Transformer magnetic shunt structure

A magnetic shunt and transformer technology, applied in the field of power transformers, can solve the problems affecting the economy and reliability of the transformer, the high temperature rise of the hot spot at the end, and the overheating of the structural parts, so as to achieve practical reliability, reduce the temperature rise of the hot spot, reduce The effect of small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

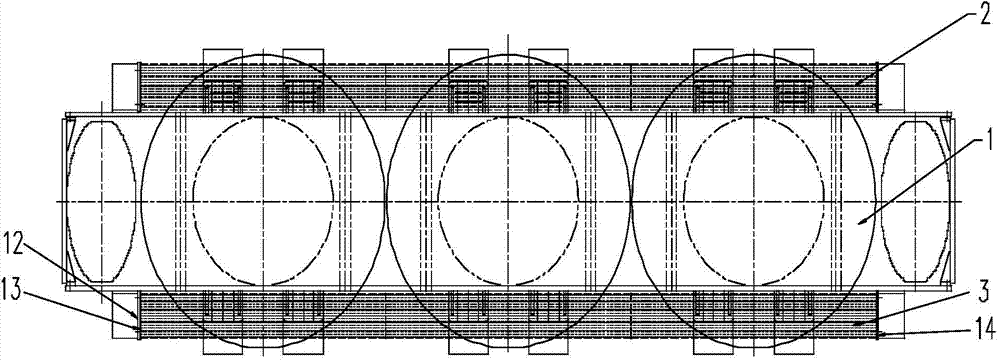

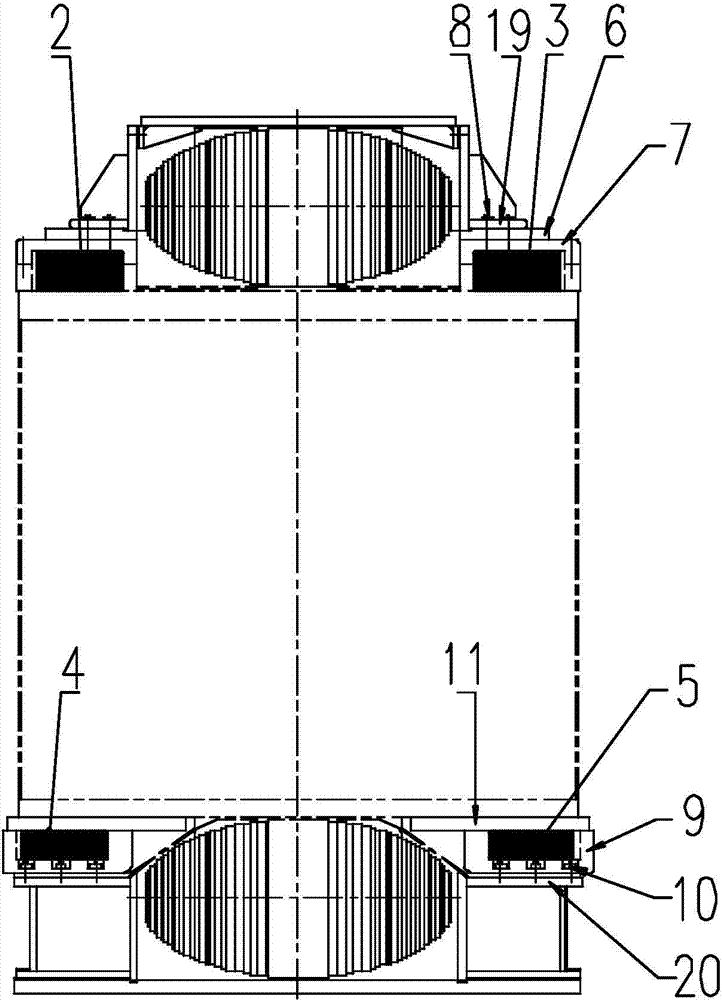

[0024] Such as Figures 1 to 3 As shown, the magnetic shunt structure of a transformer in the present invention includes an upper magnetic shunt installed above the pressure plate of the transformer 1 and a lower magnetic shunt installed under the supporting plate of the transformer 1 .

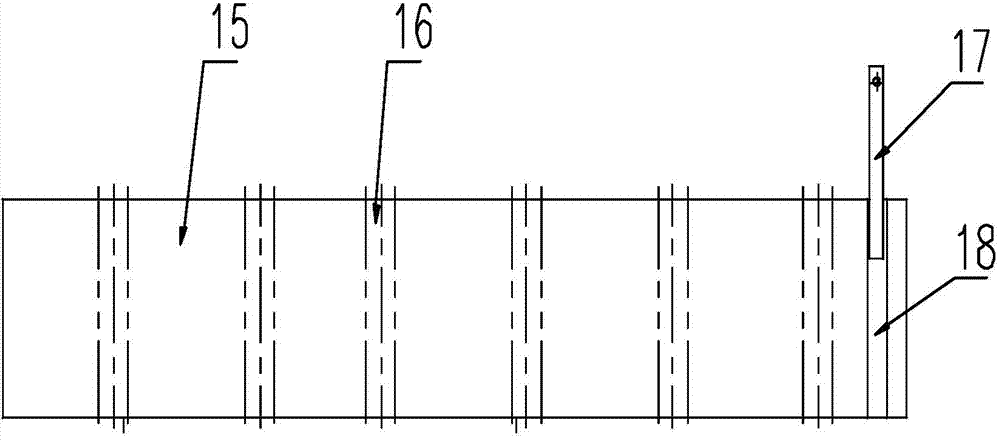

[0025] Wherein, the upper magnetic shunt includes a first upper magnetic shunt 2 and a second upper magnetic shunt 3 arranged on both sides of the upper iron yoke, and both the first upper magnetic shunt 2 and the second upper magnetic shunt 3 pass through the first upper magnetic shunt 2 and the second upper magnetic shunt 3 A fastening device is installed above the pressure plate of the transformer 1 . The first fastening device includes a first wooden part 7, a first adjusting cardboard 6 and an upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com