Clamp for cloth

A cloth clamping and horizontal plate technology, applied in the field of cloth clamps, can solve the problems of uneven test cloth force, easy crushing of test cloth, and inability to test, so as to improve reliability, improve reliability and stability, even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

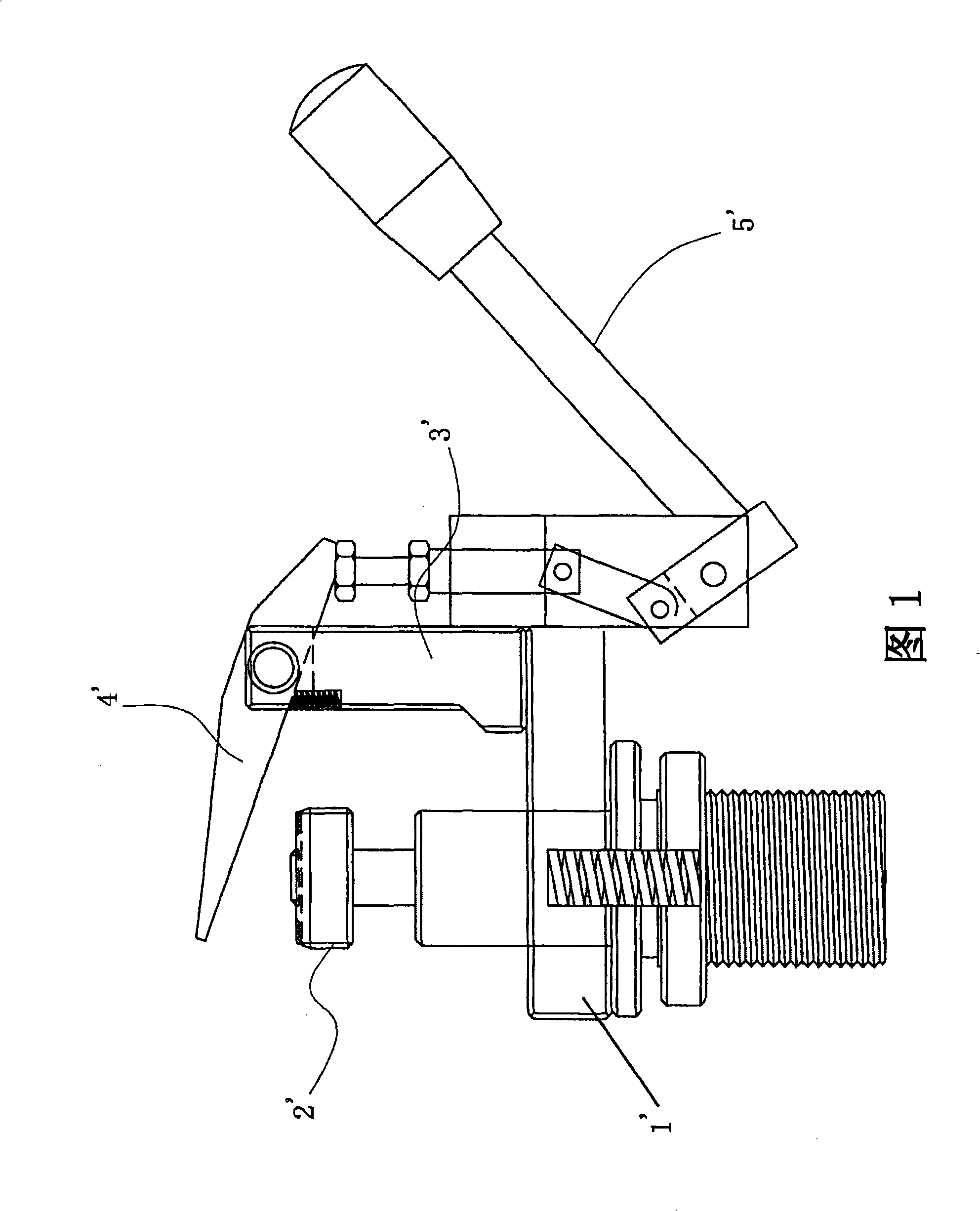

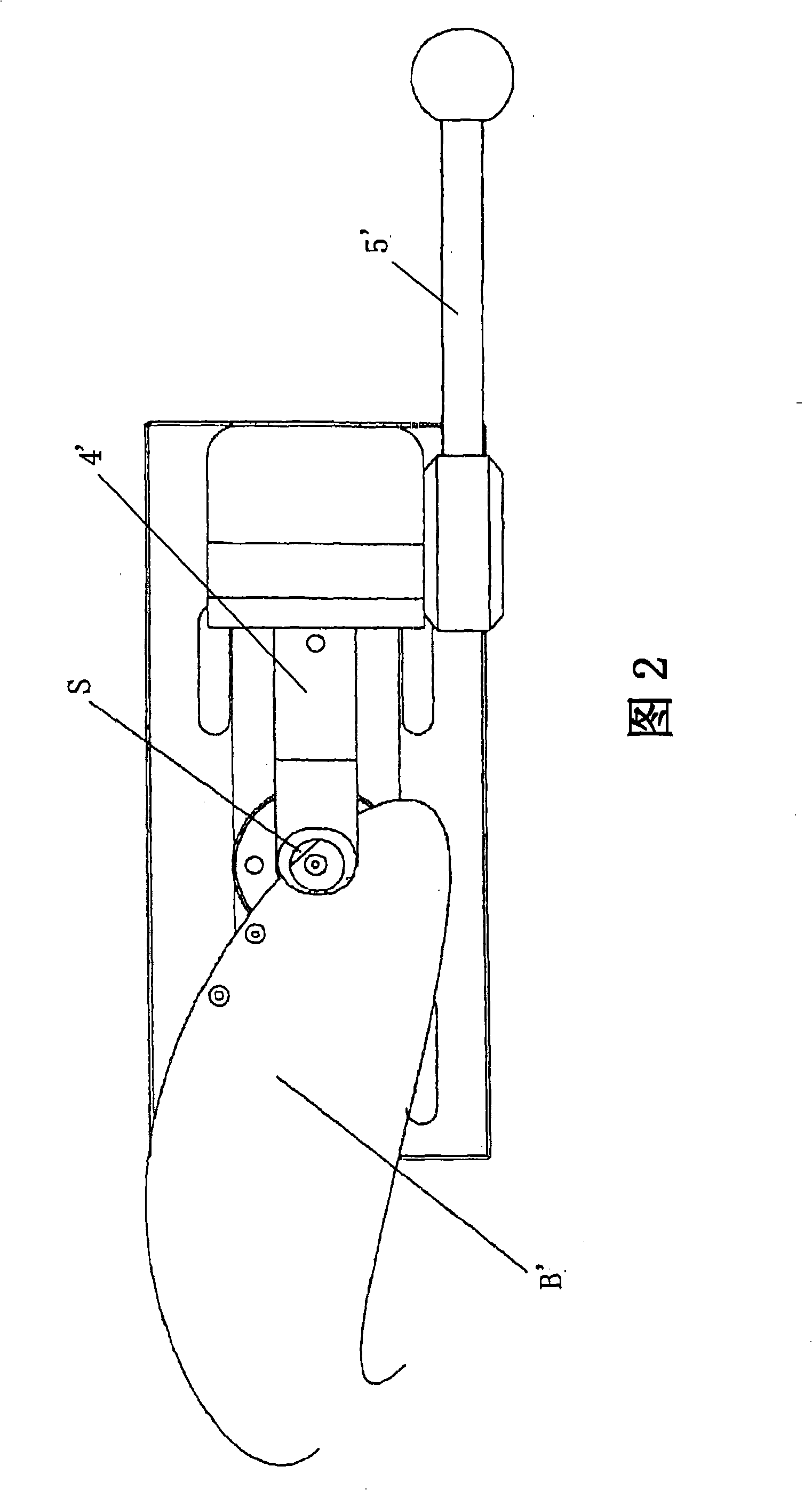

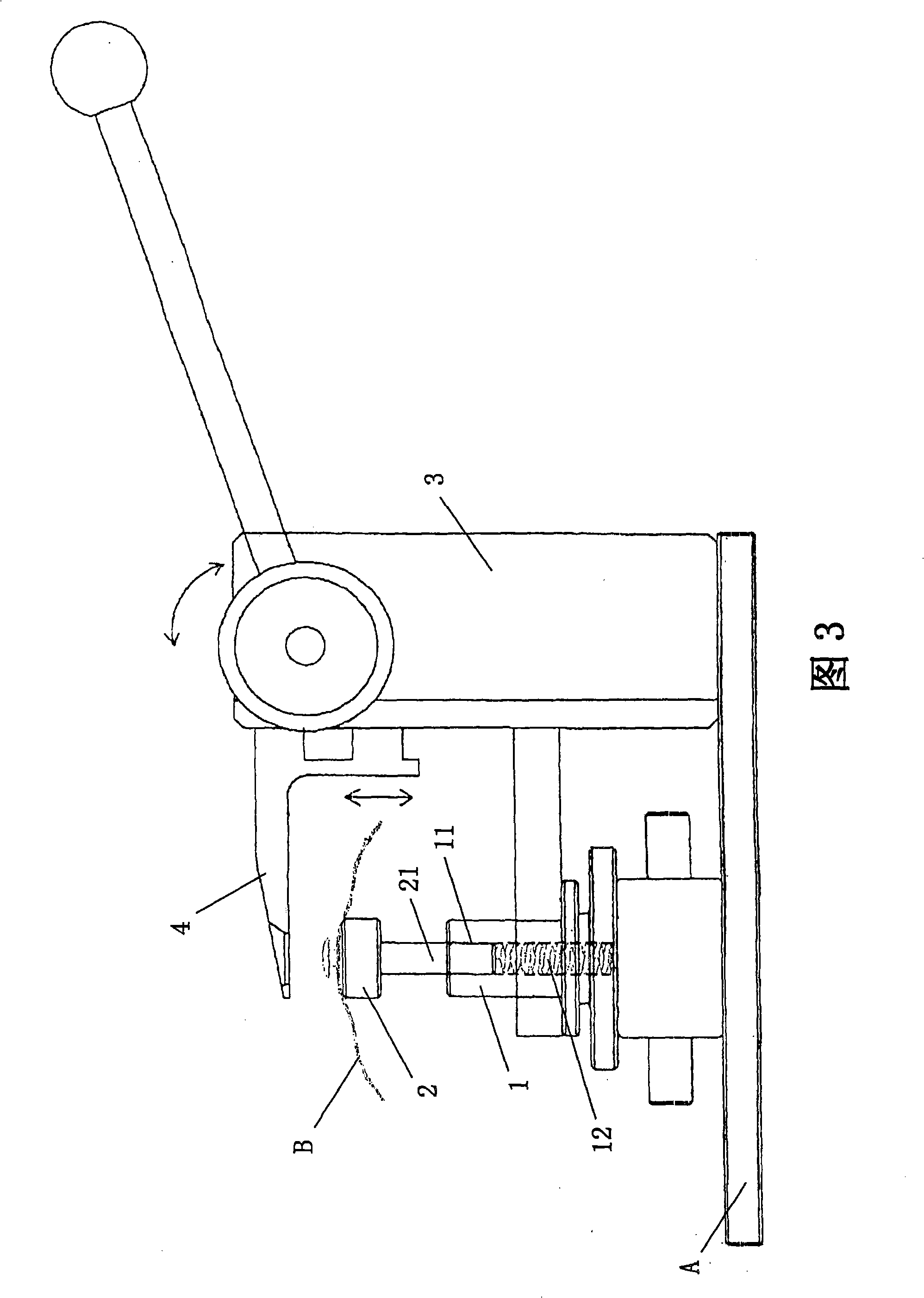

[0037] As shown in Figures 3-8, the cloth clamp pliers proposed by an embodiment of the present invention includes a fixed seat 1 that is convenient to be fixedly connected with other equipment (such as a tension machine base A), and is used for placing a test sample B (cloth for clothing) The positioning plate 2 is elastically connected to the fixed seat 1, and its top protrudes from the top of the fixed seat 1. In this embodiment, an insertion hole 11 is provided on the upper part of the fixing base 1, and an elastic element 12 is arranged inside the insertion hole 11. The column 21 of the positioning plate 2 is partially inserted into the insertion hole 11 and supported on the upper part of the elastic element 12. . The top of the positioning plate 2 adopts elastic and non-slip material, which can be non-metallic material, so as to increase the tightness and prevent the test sample from slipping away. Wherein the elastic element 12 can be a spring, more specifically a comp...

Embodiment approach 2

[0043] The difference between this embodiment and Embodiment 1 is that the combination of the operating handle 5, the support shaft 32 and the coupling block 6 is different. It is also fixedly connected, and when the operating handle 5 rotates, it drives the support shaft 32 to rotate together, and further drives the joint block 6 to rotate synchronously.

[0044] Other structures, working principles, and beneficial effects of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com