Tilling and seeding machine

A rack and deep plow technology, applied in the field of cultivators and seeders, can solve problems such as the inability to ensure that crops will not be crushed, and achieve the effects of light weight, easy control and use, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

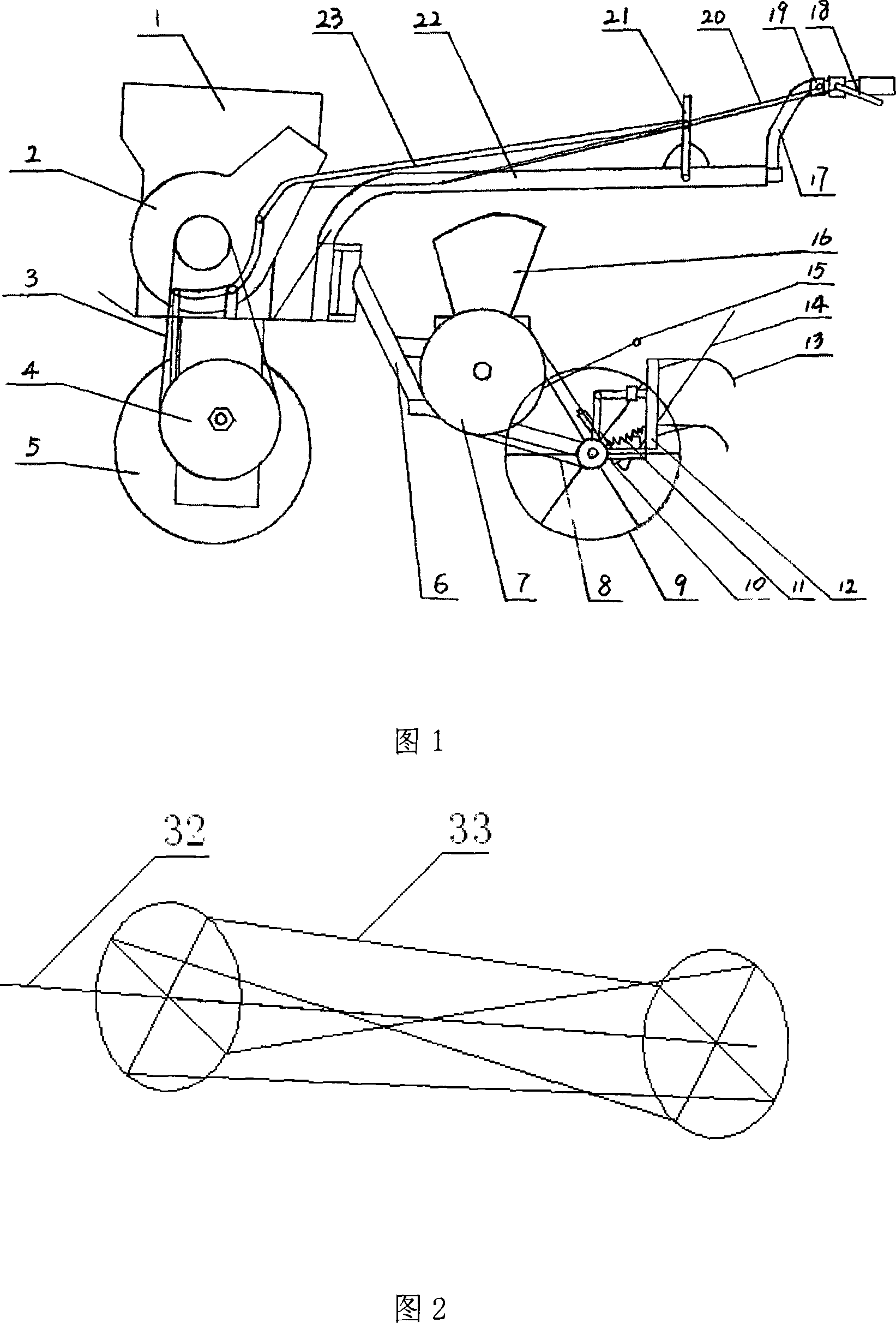

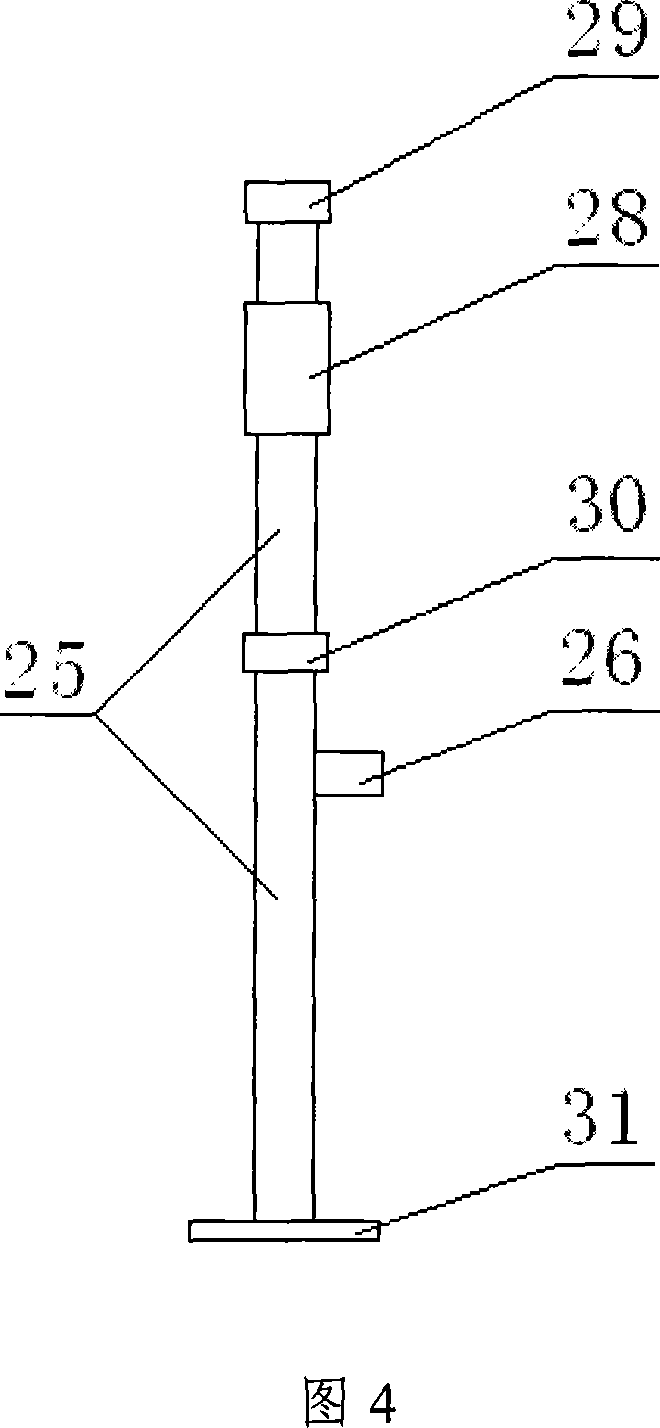

[0014] Below in conjunction with accompanying drawing, the present invention is specifically introduced as follows:

[0015] Fig. 1 is the side view of tiller-seeder of the present invention, as shown in the figure, tiller-seeder of the present invention, vehicle body overall length 130cm, comprises frame 22,, frame handle 17, power part, working part, wherein power part It is made up of diesel engine 1, transmission, a front wheel 5, shift lever 23 and shift handle 21. The power part is the source of power for the cultivator and seeder to advance. The diesel engine 1 (2.5 horsepower) rotates to drive the speed change device to rotate, and the speed change device drives the front wheel 5 to rotate to make the machine move forward. Described transmission is made up of continuously variable transmission 2, belt 3, gearbox (not shown), gearbox input wheel 4, and front wheel 5 is assembled on the output shaft of gearbox. The function of the speed change device is to convert the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com