Glass taking and placing mechanism

A glass and lifting mechanism technology, applied in the field of glass pick-and-place mechanism, can solve problems such as equipment performance or appearance damage, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

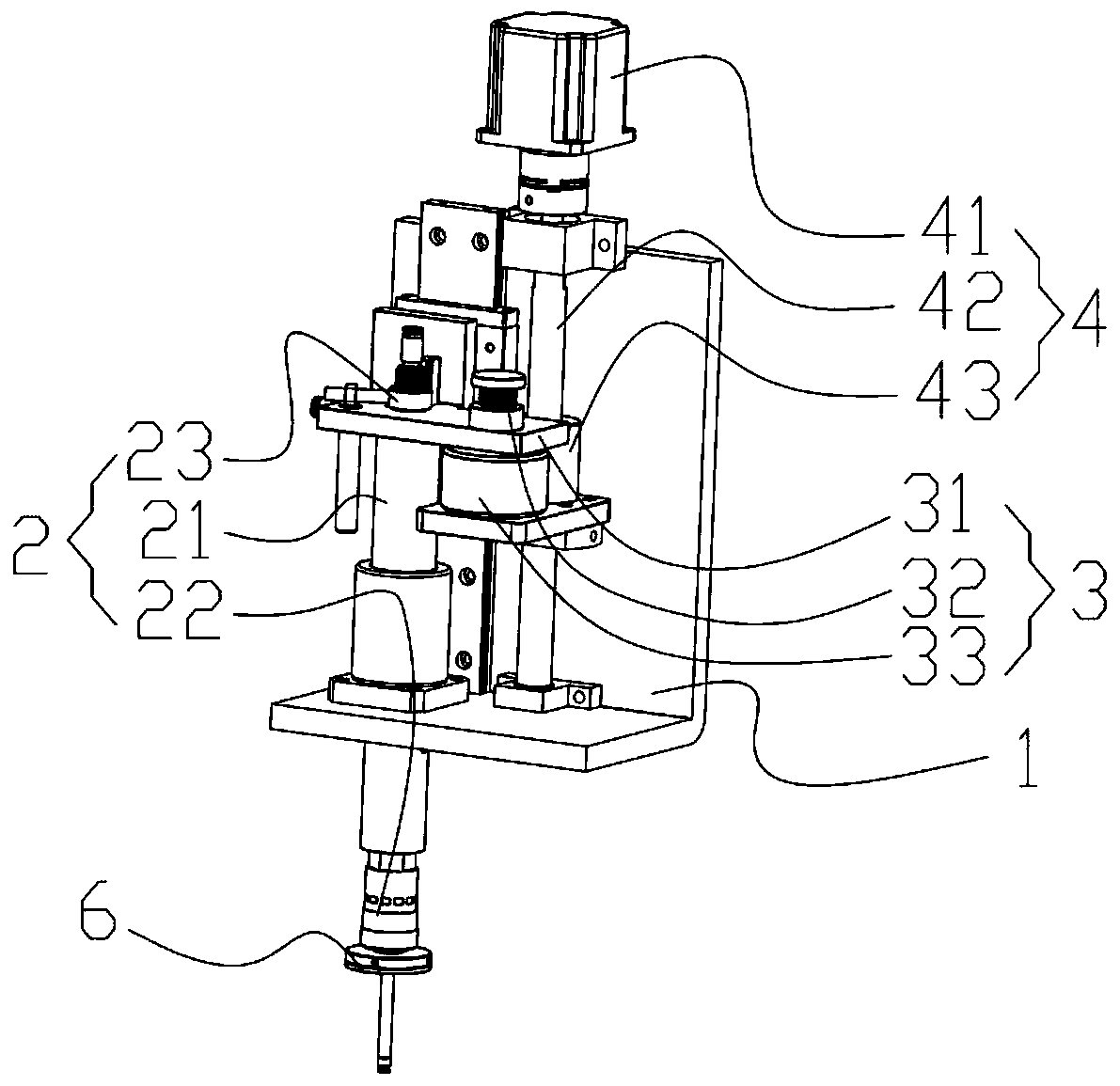

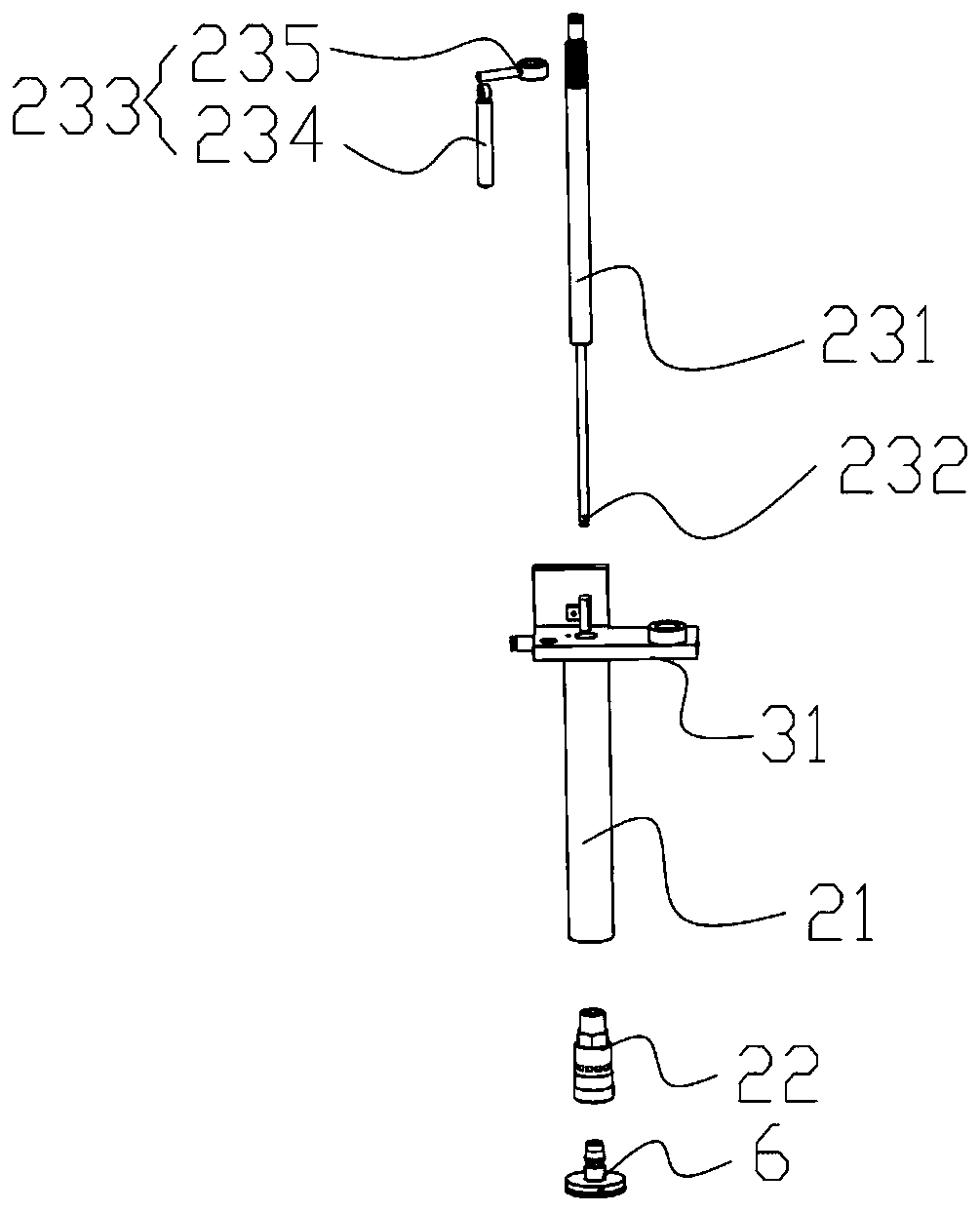

[0026] Such as figure 1 As shown, this embodiment provides a glass pick-and-place mechanism, including a base 1, an air guiding mechanism 2, a buffer mechanism 3, a lifting mechanism 4 and a suction cup 6 for sucking glass, and the lifting mechanism 4 is arranged on the The base 1, the lifting mechanism 4 is used to drive the air guiding mechanism 2 to lift, the gas guiding mechanism 2 is connected to the output end of the lifting mechanism 4 through the buffer mechanism 3, and the buffer mechanism 3 is used for Absorb the impact force between the suction cup 6 and the glass, thereby reducing the risk of the glass being crushed by the suction cup 6. The input end of the air guide mechanism 2 is used to connect an external air source, and the suction cup 6 is arranged on the air guide mechanism 2 output.

[0027] The present invention achieves the non-violent effect of removing the glass from the shell by changing the air pressure, specifically by sucking and pulling up the gl...

Embodiment 2

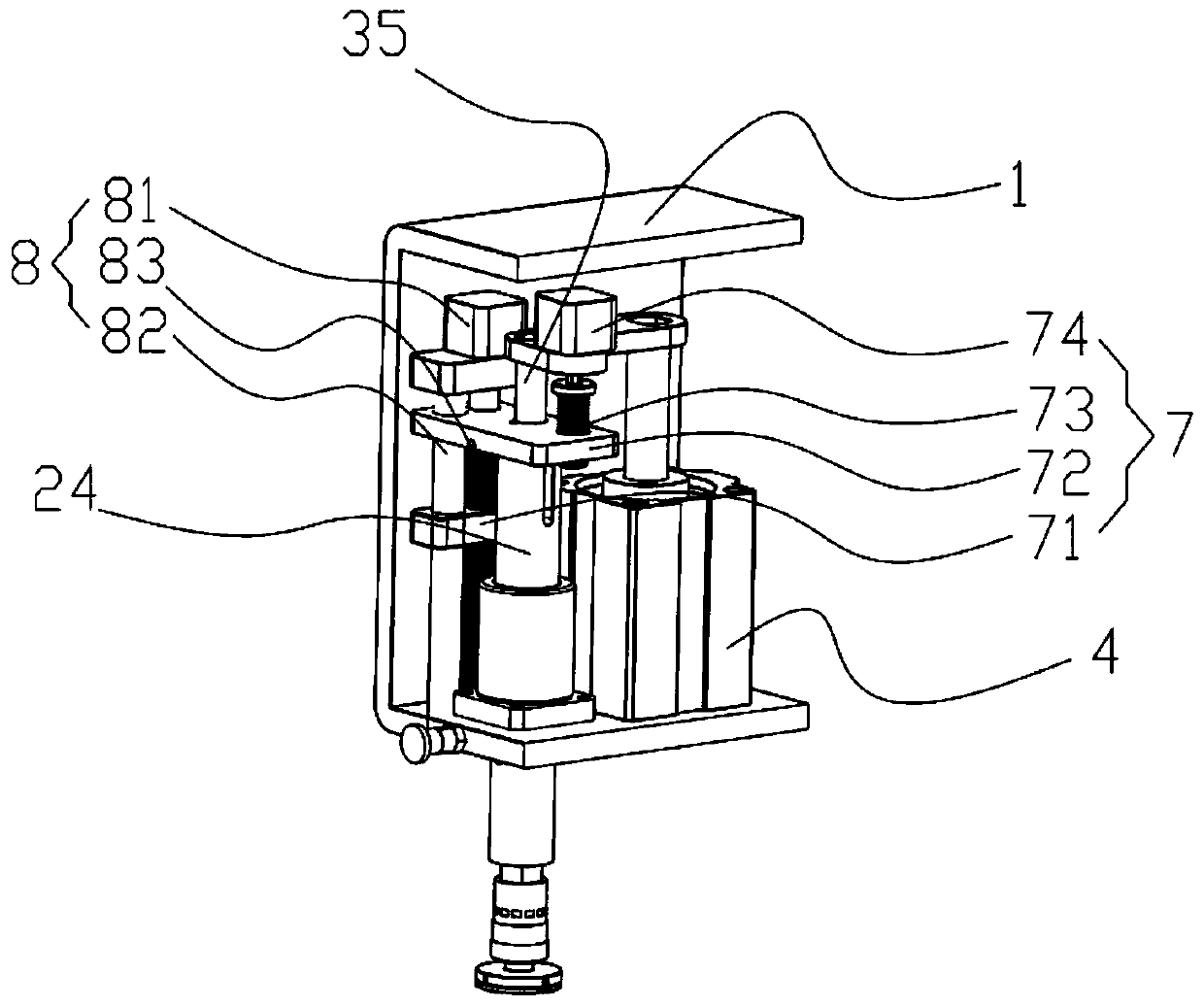

[0040] Such as image 3 with Figure 5 As shown, compared with Embodiment 1, this embodiment differs in the structure of the buffer mechanism 3 and the structure of the air guide mechanism 2, specifically: the air guide mechanism 2 is not provided with an inner air guide mechanism 23, that is, the air guide mechanism 2 Including air guide sleeve 24, quick joint 22 and suction cup 6, suction cup 6 is installed on air guide sleeve 24 through quick joint 22, and the input end of air guide sleeve 24 (i.e. air inlet 242) is arranged on one side of air guide sleeve 24 On the side, the top of the air guide sleeve 24 is provided with a blind hole 241; the buffer mechanism 3 includes a force unloading member (not marked in the figure) and a pressure rod 35, and the pressure rod 35 and the air guide mechanism 2 are all arranged on The output end of the lifting mechanism 4, the force unloading member is arranged in the blind hole 241, the pressure rod 35 is movably assembled in the blin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com