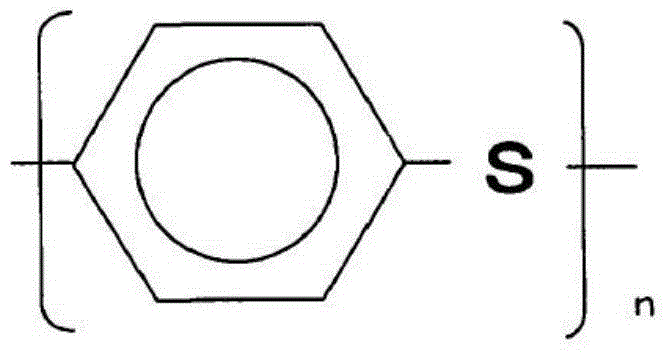

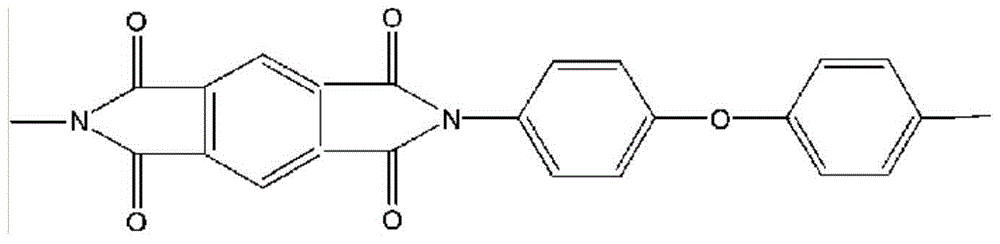

Fabric comprising fire-retardant yarn of blended polymer fiber containing aromatic polyamide and polyarylsulfone and production method of fabric

A technology of aromatic polyamides and blended polymers, applied in the field of flame-retardant yarns, can solve problems such as obvious droplet phenomenon, difficult dyeing, secondary damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

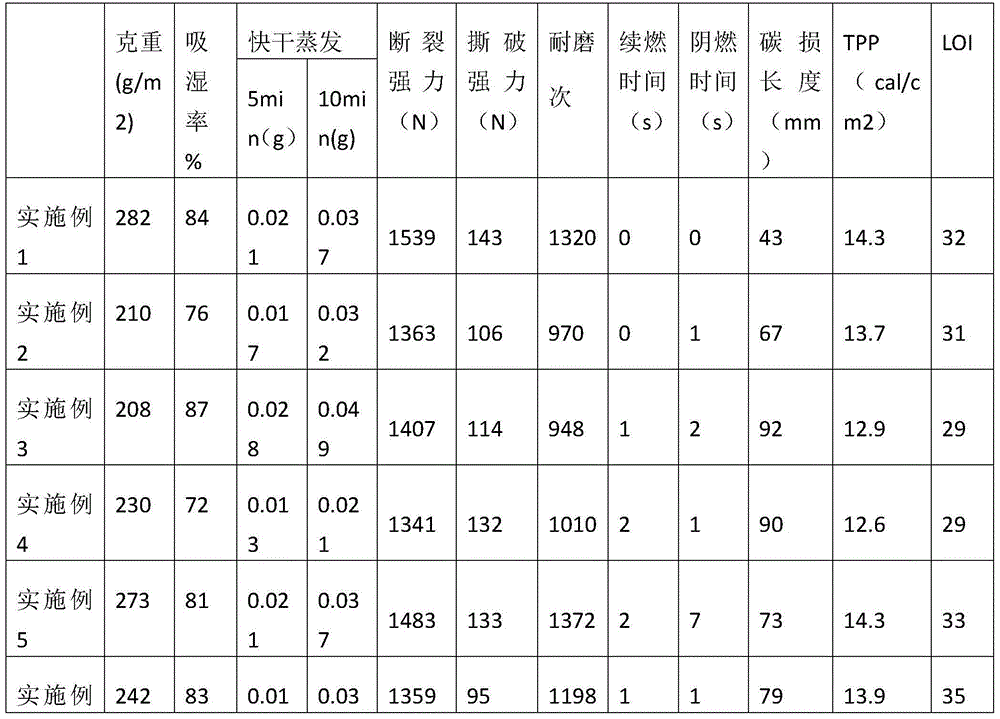

[0158] The fiber weight ratio is: 30% of the blended polymer fiber of aromatic polyamide and polyarylsulfone, 20% of flame-retardant nylon, 35% of flame-retardant viscose, 15% of aramid 1414, four kinds of fibers are passed through conventional cotton spinning system equipment The prepared clear cotton blended sliver is then spun into a 24s spun yarn by a ring spinning frame, and then plied by a plying machine to make a flame-retardant 24s / 2 ply yarn as a weaving warp. Using the same similar process and blending ratio, 20s / 2 is used as weaving weft yarn. The natural color twill fabric with a weight of 267g / m2 is produced by air-jet weaving. The washed fabric is spray dyed in the overflow dyeing vat. The resulting colored finished fabric has a gram weight of 282g / m2.

Embodiment 2

[0160] The fiber weight ratio is: 25% of the blended polymer fiber of aromatic polyamide and polyarylsulfone, 30% of flame-retardant nylon, 35% of flame-retardant viscose, 10% of aramid 1414, the four types of fibers are passed through conventional cotton spinning system equipment The prepared clear cotton blended sliver is then spun into a 30s spun yarn by a compact spinning frame, and then twisted by a twisting machine to make a flame-retardant 30s / 2 ply yarn as a weaving warp. Using the same similar process and blending ratio to make 28s / 2 as weaving weft yarn. A natural twill fabric with a weight of 203g / m2 is produced through a shuttle loom. The washed fabric is spray dyed in the overflow dyeing vat. The resulting colored finished fabric has a weight of 210g / m2.

Embodiment 3

[0162] The fiber weight ratio is: 20% of the blended polymer fiber of aromatic polyamide and polyarylsulfone, 35% of flame-retardant nylon, 40% of flame-retardant viscose, 5% of aramid 1414, the four types of fibers pass through conventional cotton spinning system equipment The prepared clear cotton blended sliver is then spun into a 32s spun yarn by a compact spinning frame, and then plied by a twister to make a flame-retardant 32s / 2 ply yarn as a weaving warp. A plain weave fabric with a basic color of 201g / m2 is produced by weaving a shuttle loom. The washed fabric is spray dyed in the overflow dyeing vat. The resulting colored finished fabric has a weight of 208g / m2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com