Patents

Literature

49results about How to "Solve the problem of not being able to withstand high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional organic silicon thermal interface material

InactiveCN104497574AImprove thermal conductivitySimple preparation processGlass fiberPolyimide membrane

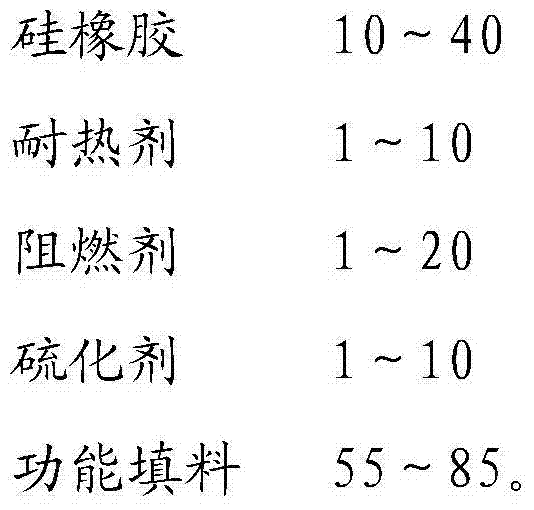

The invention relates to a multifunctional organic silicon thermal interface material. The thermal interface material is formed by compounding the following components in percentage by weight: 10-40% of silicone rubber, 1-10% of a heat resistant agent, 1-20% of a flame retardant, 1-10% of a sulfurizing agent and 55-85% of a functional filler. The thermal interface material is a flaky material formed by mixing the silicone rubber, the heat resistant agent, the flame retardant, the sulfurizing agent and the functional filler according to the proportion, and coating or calendering a mixture on glass fiber cloth or a polyimide film. The organic silicon thermal interface material provided by the invention has high temperature resistance and good heat conduction, insulation and flame retardance, thereby effectively ensuring normal working of electronic equipment.

Owner:SHENZHEN BORNSUN INDAL

Method for preparing egg and milk essence substrate

ActiveCN102232534AImprove securityAdd flavorAnimal feeding stuffWorking-up animal fodderMonoglycerideButterfat

The invention relates to the technology in the field of food and beverage processing, in particular to preparation of an egg and milk essence substrate by using a dual enzymatic method in cooperation with the mailard reaction; and the prepared egg and milk essence substrate can be widely applied to various food industries. The method comprises the following steps of: hydrolyzing natural cream by using lipase and subjecting dried egg yolk to enzymolysis by using protease; mixing a hydrolysis product and an enzymolysis product based on a certain ratio, homogenizing by a homogenizer, and obtain a homogenous emulsification system by using the monoglyceride and lecithin in a mixture per se as emulsifiers; then adding reducing sugar-xylose and amino acid-methionine for producing the egg characteristic flavor, mixing to reach a uniform state, directly heating to 105-110 DEG C, reacting for 1-3 hours; and performing the mailard reaction and enzyme deactivation at the same time. A final product has the flavor mixture of free fatty acid, lactone, methyl ketone, alcohol, aldehyde, black-like essence with antioxidant activity and the like, wherein the free fatty acid is obtained through hydrolyzing the fat, the lactone, methyl ketone, alcohol and aldehyde are obtained through heating the fat, and the black-like essence is generated by the mailard reaction; and thus, the product has an intense egg and milk flavor.

Owner:GUANGZHOU FLOWER FLAVOURS & FRAGRANCES

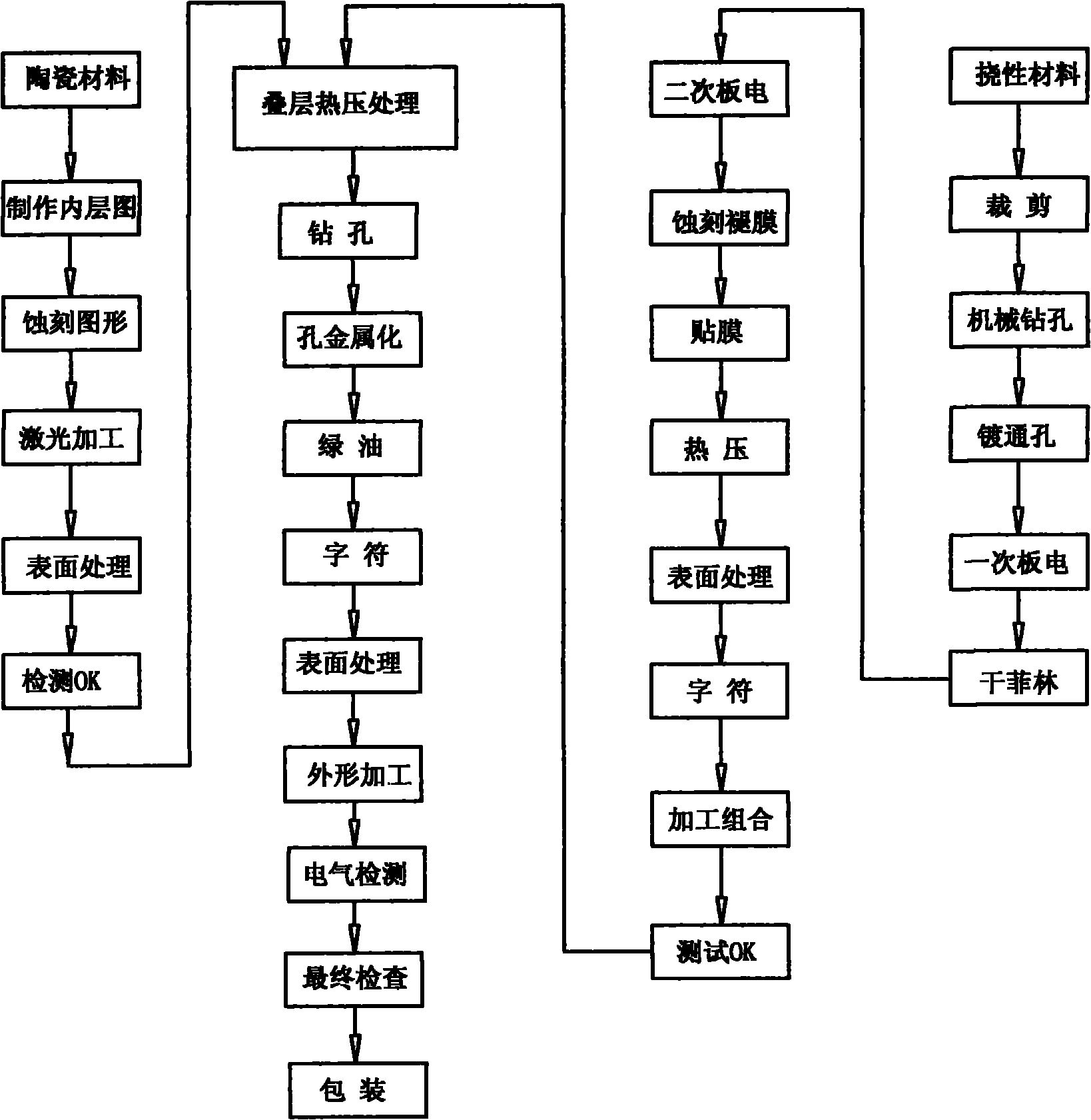

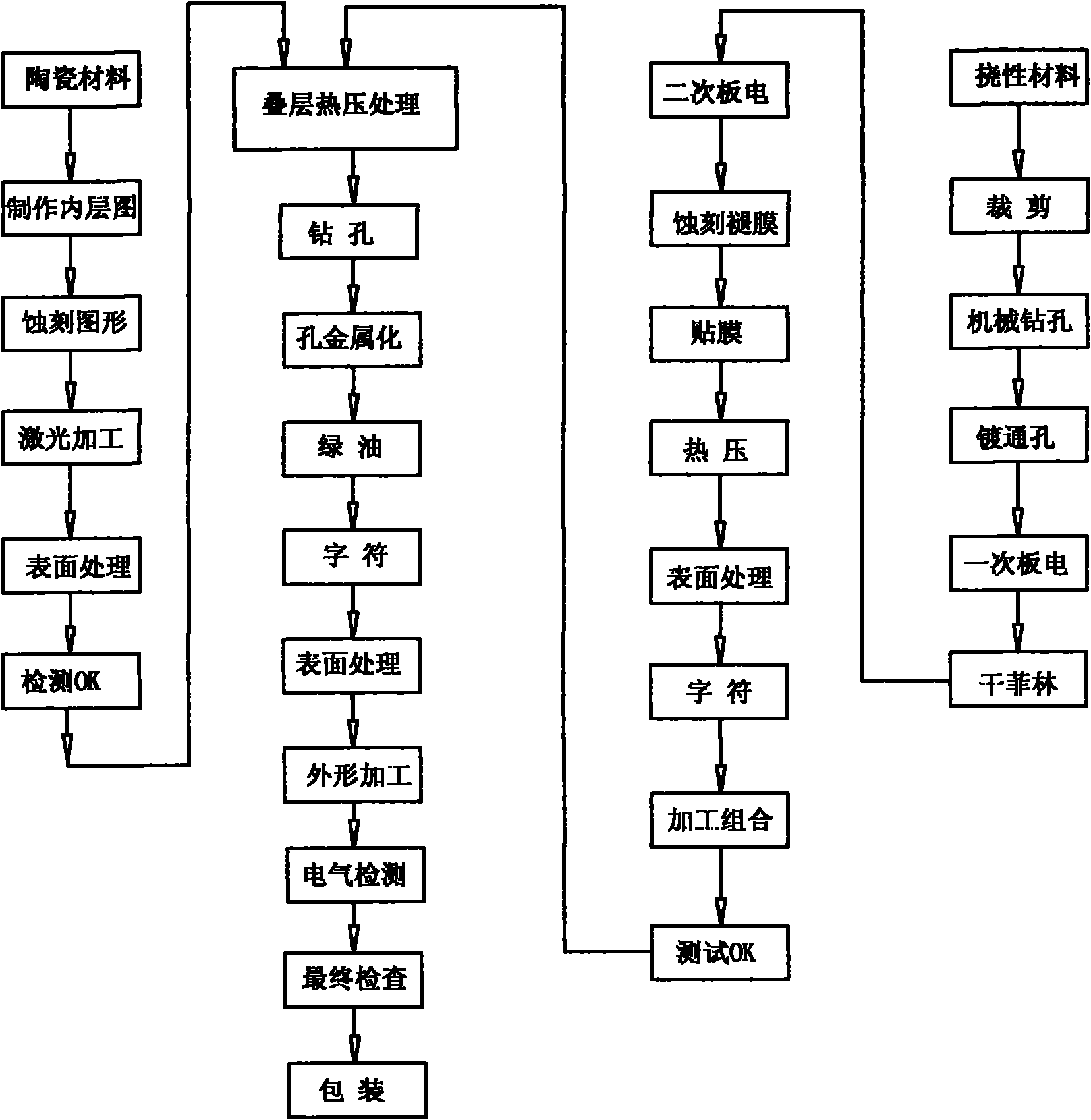

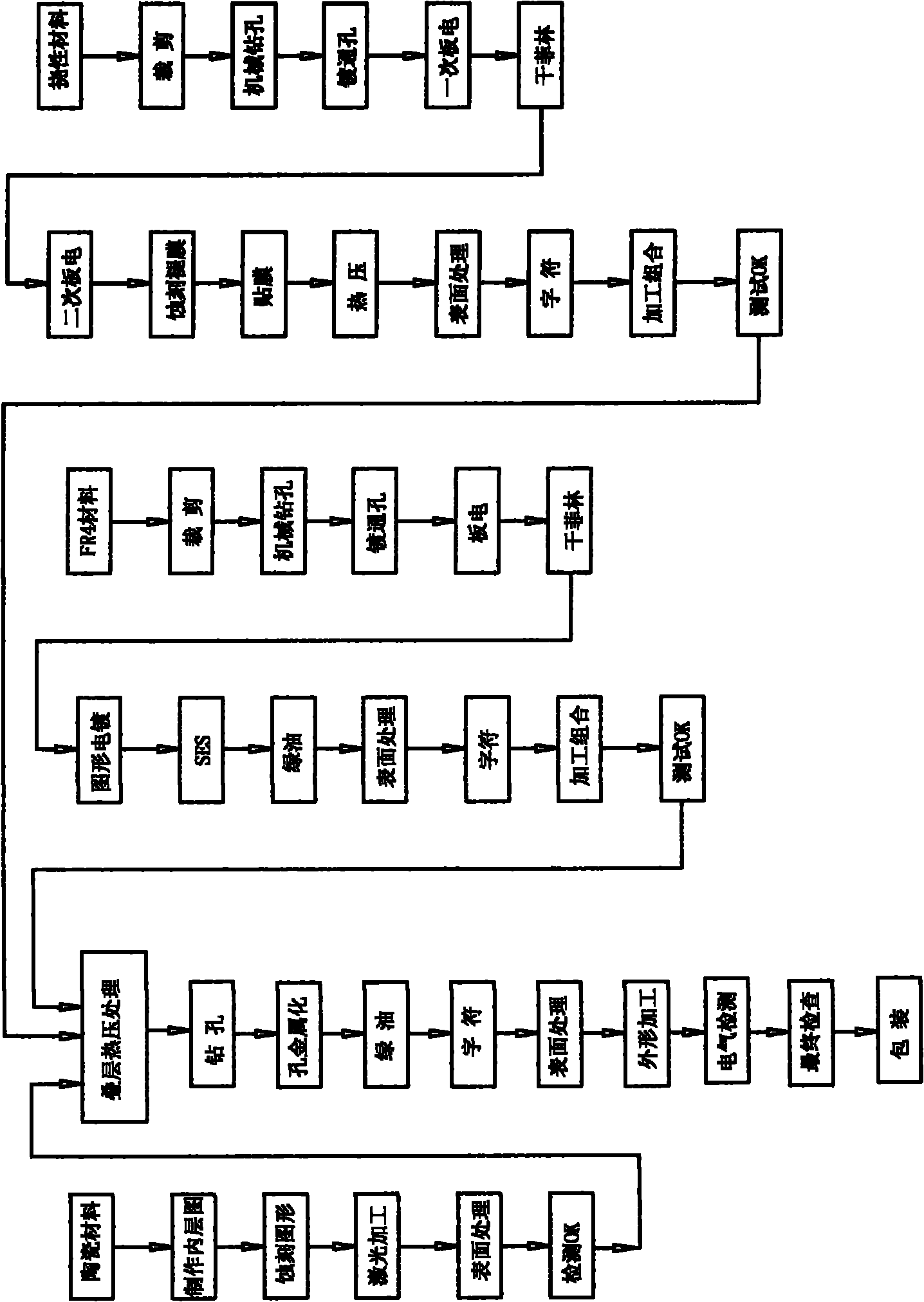

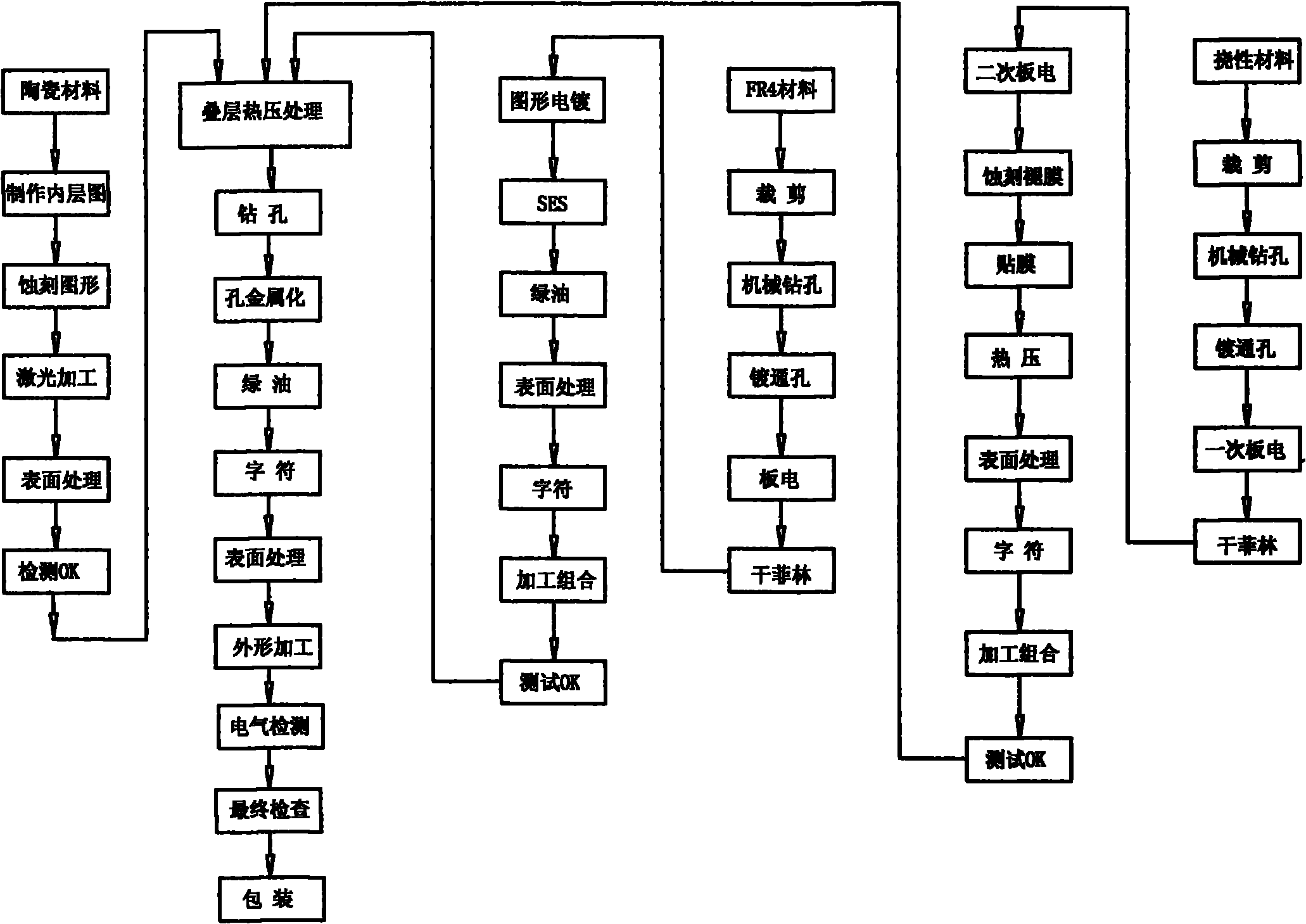

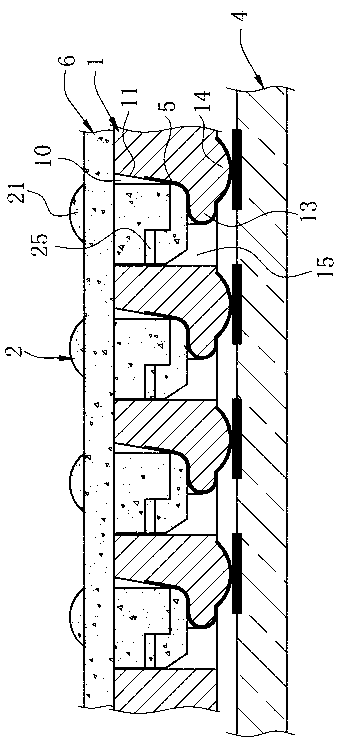

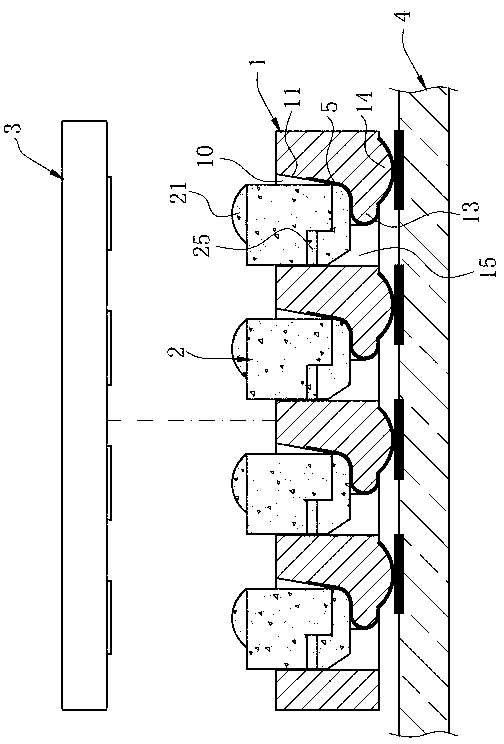

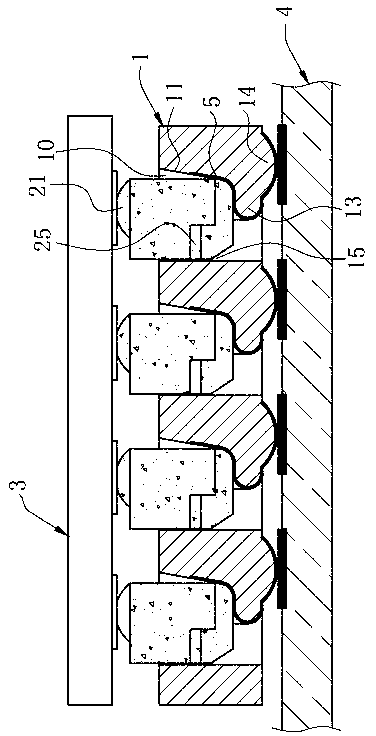

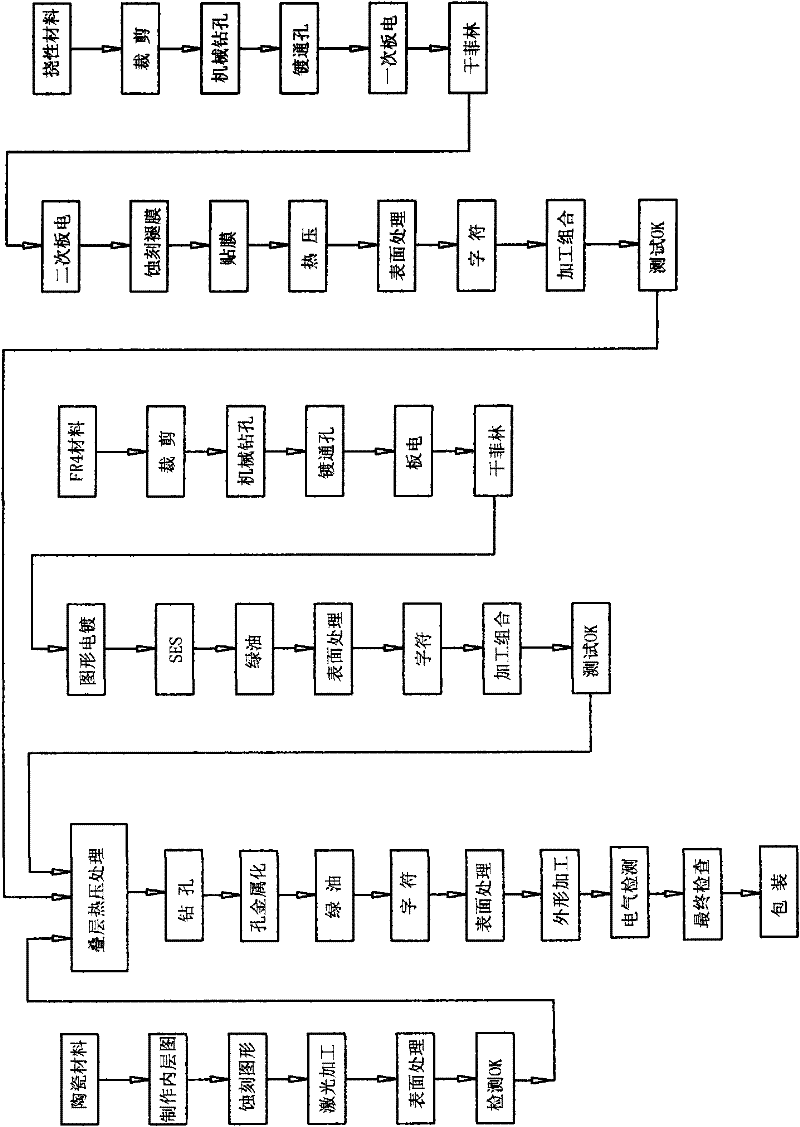

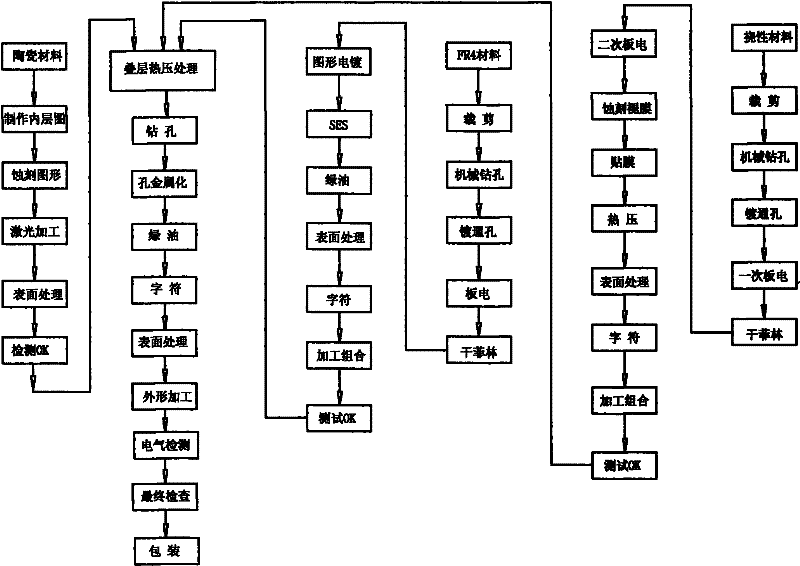

Method for manufacturing ceramic-based flexible circuit board

InactiveCN101990369ASolve the problem of high temperature resistanceExcellent 3D connection characteristicsMultilayer circuit manufactureCeramicResist

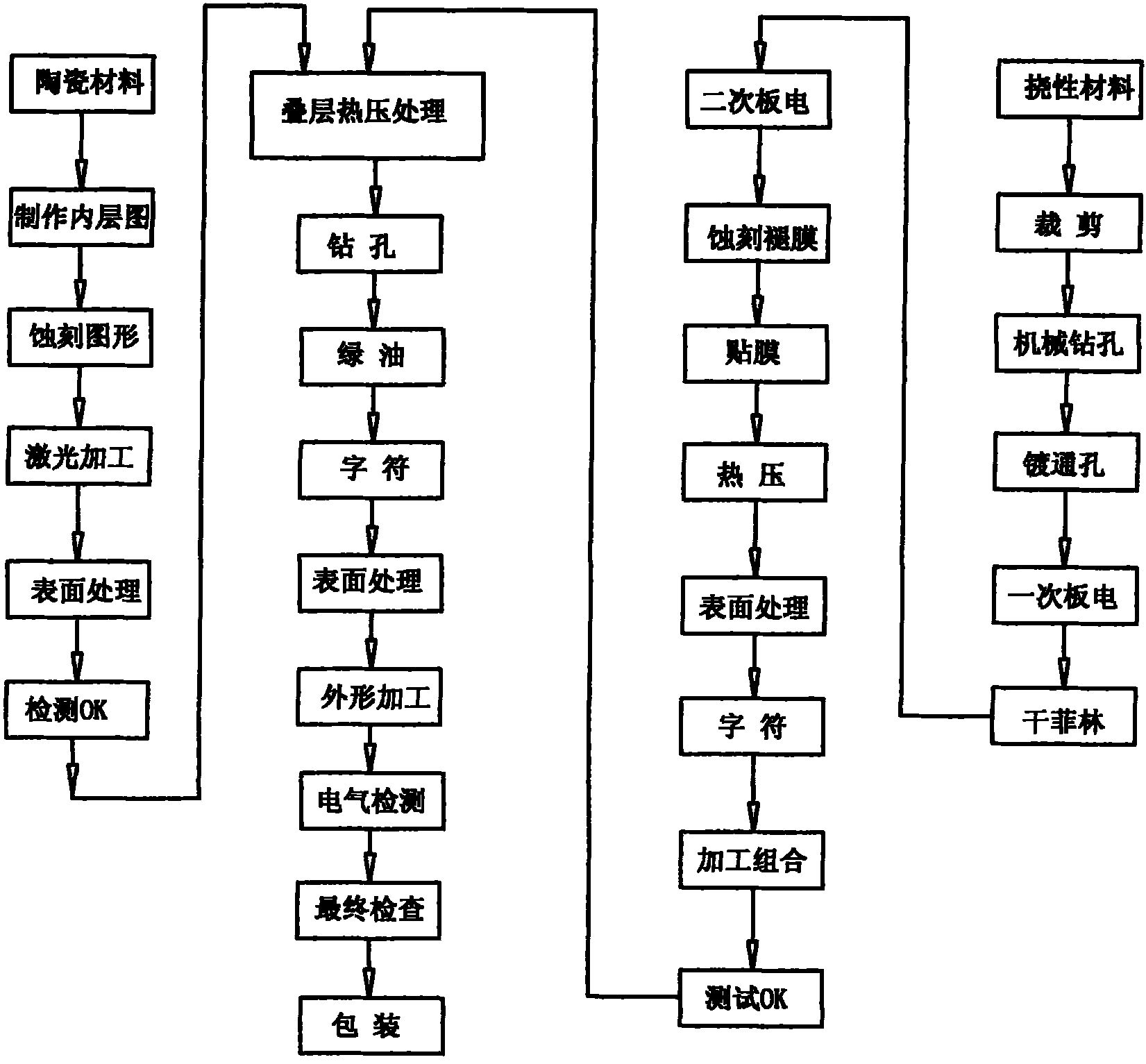

The invention discloses a method for manufacturing a ceramic-based flexible circuit board, which is characterized by comprising the following steps of: A. manufacturing an aluminum nitride ceramic circuit board; B. manufacturing a flexible circuit board; C. laminating the aluminum nitride ceramic circuit board and the flexible circuit board; D. manufacturing a through hole passing through the upper surface and the lower surface of the multilayer board on the multilayer board obtained in the step C by adopting laser drilling equipment, processing the hole with a conducting material and then drying to obtain a through hole; E. printing solder resist ink in the positions on the multilayer board, at which electronic elements do not need to be welded; F. silk printing characters at preset positions on the multilayer board; and G. cutting the circuit board into predetermined specifications by adopting laser cutting equipment to obtain the ceramic-based rigid flexible multilayer circuit board. The invention aims to overcome the defects in the prior art and provide the manufacturing method of the ceramic-based flexible circuit board with simple process, good 3D connection performance and good thermal conductivity.

Owner:广东达进电子科技有限公司

Manufacture method of ceramic-based interconnection flexible circuit board

InactiveCN101990371AOvercoming brittlenessOvercome difficultyMultilayer circuit manufacturePunchingFlexible circuits

The invention discloses a manufacture method of a ceramic-based interconnection flexible circuit board, which is characterized by comprising the following steps of: A, manufacturing an aluminum nitride ceramic circuit board; B, manufacturing a flexible circuit board; C, laminating the aluminum nitride ceramic circuit board and the flexible circuit board; D, manufacturing a through hole penetrating the upper surface and the lower surface of a multilayer board in the step C on the multilayer boardby adopting a laser punching device, penetrating the through hole by adopting a conductive material and then drying to ensure that the through hole becomes a conducting hole; E, printing welding-preventing ink on the place of the multilayer board where no electric component is welded; F, silk-screening characters on the preset place of the multilayer board; and G, cutting the circuit boards into preset specifications by adopting a laser cutting device to obtain the ceramic-based rigid flexible multilayer circuit board. The invention aims at overcoming the defects in the prior art, and provides the manufacture method of the ceramic-based interconnection flexible circuit board with excellent 3D connection characteristic and better thermal conductivity.

Owner:广东达进电子科技有限公司

Method for manufacturing ceramic-based interconnected rigid flexible combined multilayer circuit board

InactiveCN101990373ASolve the problem that it is difficult to achieve interlayer conduction through electroplatingSolve the problem of not being able to withstand high temperatureMultilayer circuit manufactureResistFlexible circuits

The invention discloses a method for manufacturing a ceramic-based interconnected rigid flexible combined multilayer circuit board, which is characterized by comprising the following steps of: A. manufacturing an aluminum nitride ceramic circuit board; B. manufacturing a flexible circuit board; C. manufacturing an epoxy resin circuit board; D. laminating the aluminum nitride ceramic circuit board, the flexible circuit board and the epoxy resin circuit board; E. manufacturing a through hole passing through the upper surface and the lower surface of the multilayer board on the multilayer board obtained in the step D by adopting laser drilling equipment, processing the hole with a conducting material, then drying to obtain a through hole; F. printing solder resist ink in positions on the multilayer board, at which electronic elements do not need to be welded; G. silk printing characters in preset positions on the multilayer board; and H. cutting the circuit board into predetermined specifications by adopting laser cutting equipment to obtain the ceramic-based rigid flexible multilayer circuit board. The invention provides the manufacturing method of the ceramic-based interconnected rigid flexible combined multilayer circuit board with simple process, high wiring density, good 3D connection performance and good thermal conductivity.

Owner:广东达进电子科技有限公司

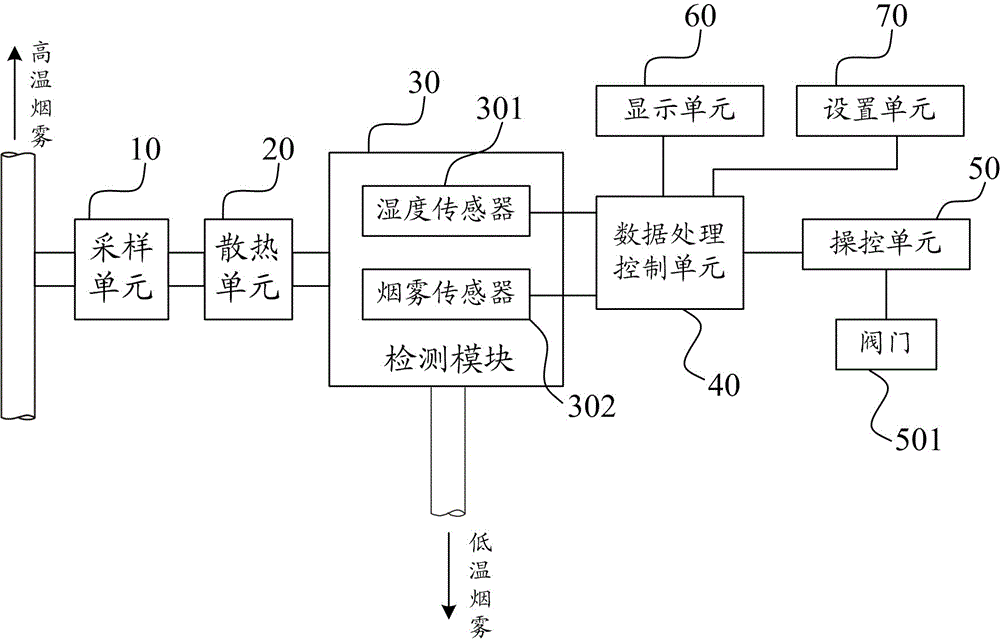

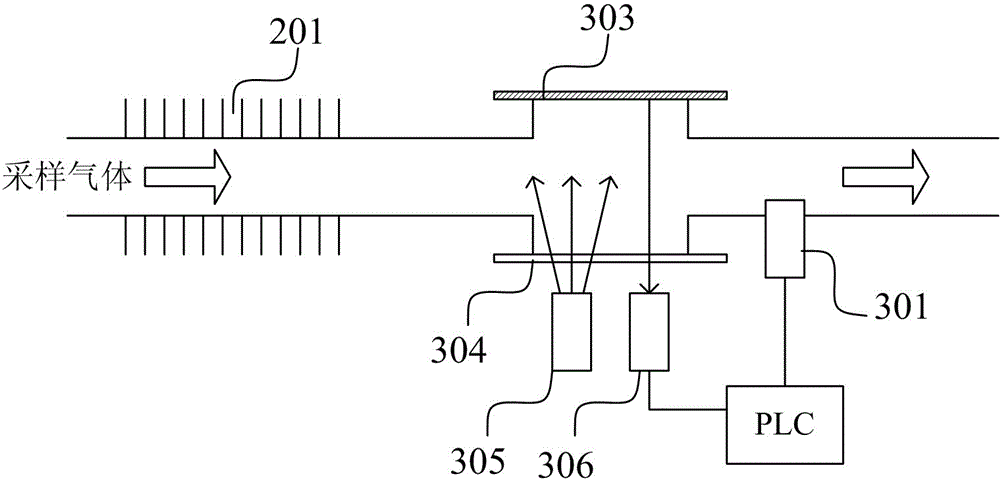

Fabric shaping/dryer energy conservation and emission reduction control system and method for textile and dying industry

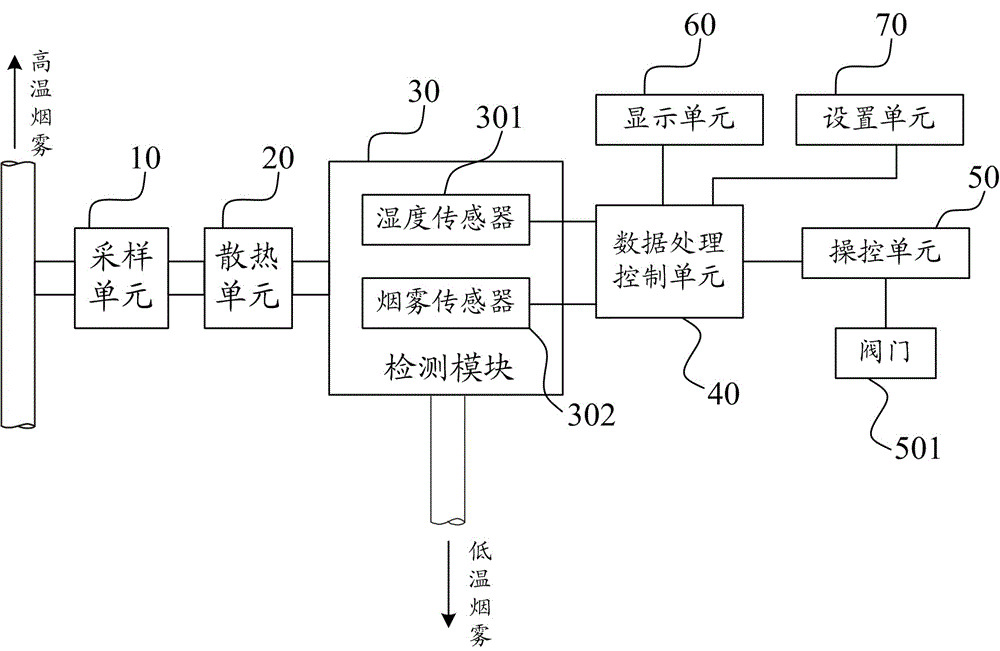

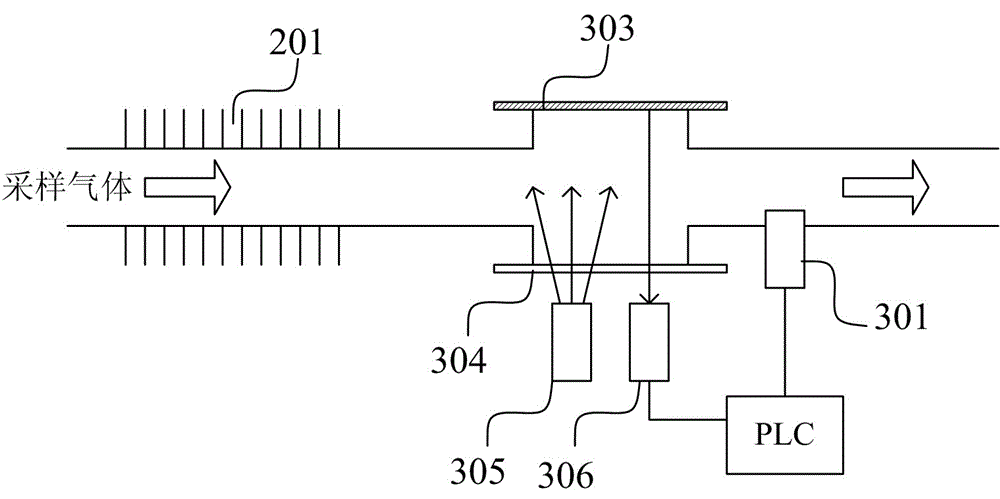

ActiveCN103184667ASolve the problem of not being able to withstand high temperatureImprove printing and dyeing effectTextile treatment machine arrangementsExhaust valveControl signal

An embodiment of the invention discloses a fabric shaping / dryer energy conservation and emission reduction control system for the textile and dying industry. The control system comprises a sampling unit, a radiating unit, a detection module, a data processing control unit, a control unit, a display unit and a setting unit, wherein the sampling unit obtains sampling gas, and the sampling gas is cooled by the radiating unit; the data processing control unit compares values, detected by a humidity sensor and / or a smoke sensor, of the cooled sampling gas with a set value; and a control signal is output to control the opening degree of an exhaust valve, so that exhaust operation is performed. The embodiment of the invention further discloses a clothes shaping and drying energy conservation and emission reduction control method. When the control system and method are adopted, the problem that the humidity sensor or the smoke sensor are not high temperature resistant is solved, the detection values of the humidity sensor and / or the smoke sensor are chosen to be compared with a set value according to different technologies, and the opening degree of the exhaust valve is controlled, so that optimal working parameters are maintained, and a large amount of energy is avoided from being consumed by exhaust by mistake.

Owner:李川凌

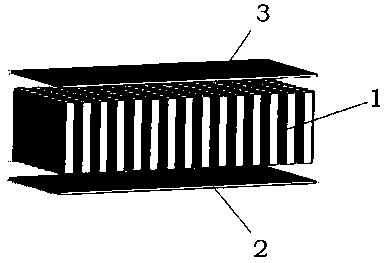

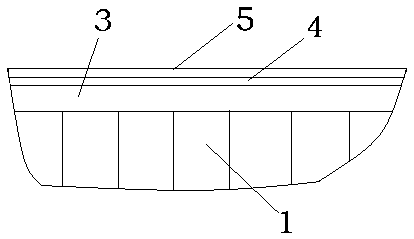

High-temperature thermal transfer decoration method for abrasion-resistant aluminum honeycomb panel of rail transit interior decoration and product

ActiveCN109291675AImproved abrasion and weather resistanceImprove the effectDecorative surface effectsDuplicating/marking methodsWood grainHigh pressure

The invention relates to a high-temperature thermal transfer decoration method for an abrasion-resistant aluminum honeycomb panel of rail transit interior decoration and a product. A honeycomb panel core of the aluminum honeycomb panel and two panels are combined and welded through spot welding and brazing to form the high-temperature resistant aluminum honeycomb panel; the surface of the aluminumhoneycomb panel is pretreated, then a layer of resin base powder is sprayed to the surface of the aluminum honeycomb panel through high voltage static, and the resin base powder is cured at the hightemperature being 210 to 280 DEG C; after the resin base powder is cured, woodgrained paper is pasted to the resin base powder; and then the aluminum honeycomb panel provided with the woodgrained paper in a pasted manner is placed into an oven for high-temperature thermal transfer at 210-260 DEG C, so that the surface of the aluminum honeycomb panel has the effect of natural wood grains, and the decoration effect the same as that of natural wood is achieved.

Owner:株洲九方因赛德技术有限公司

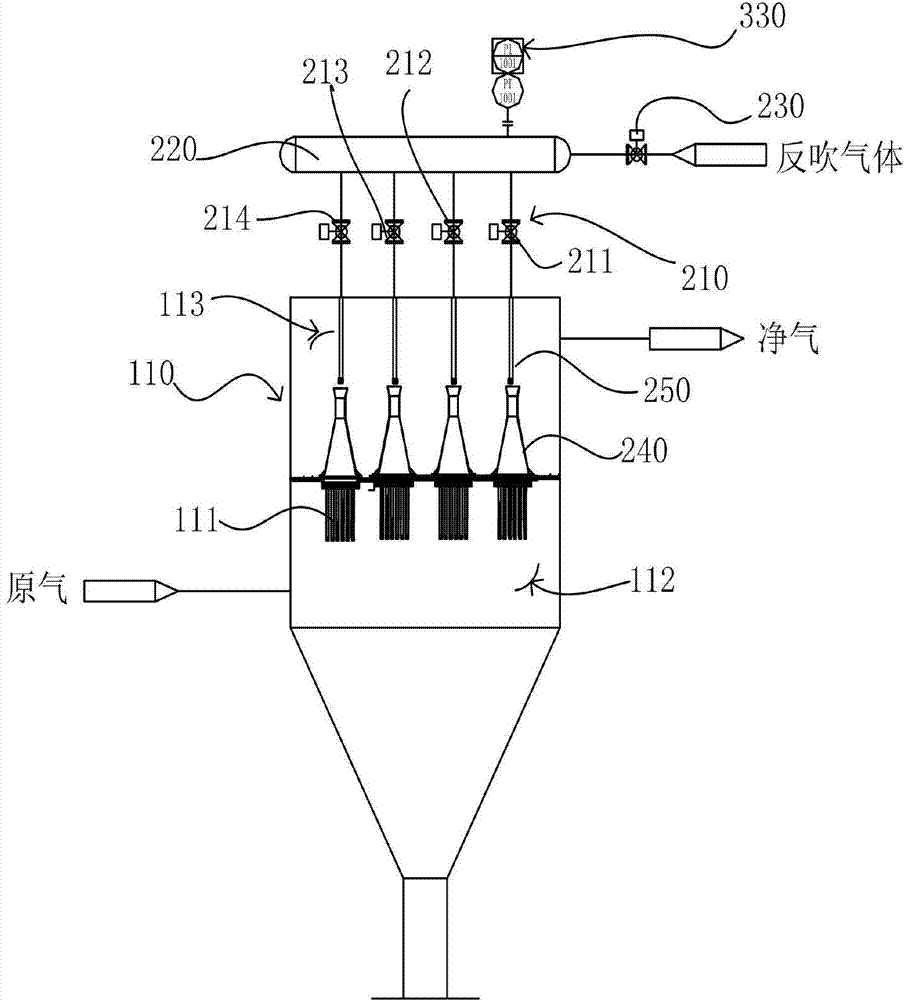

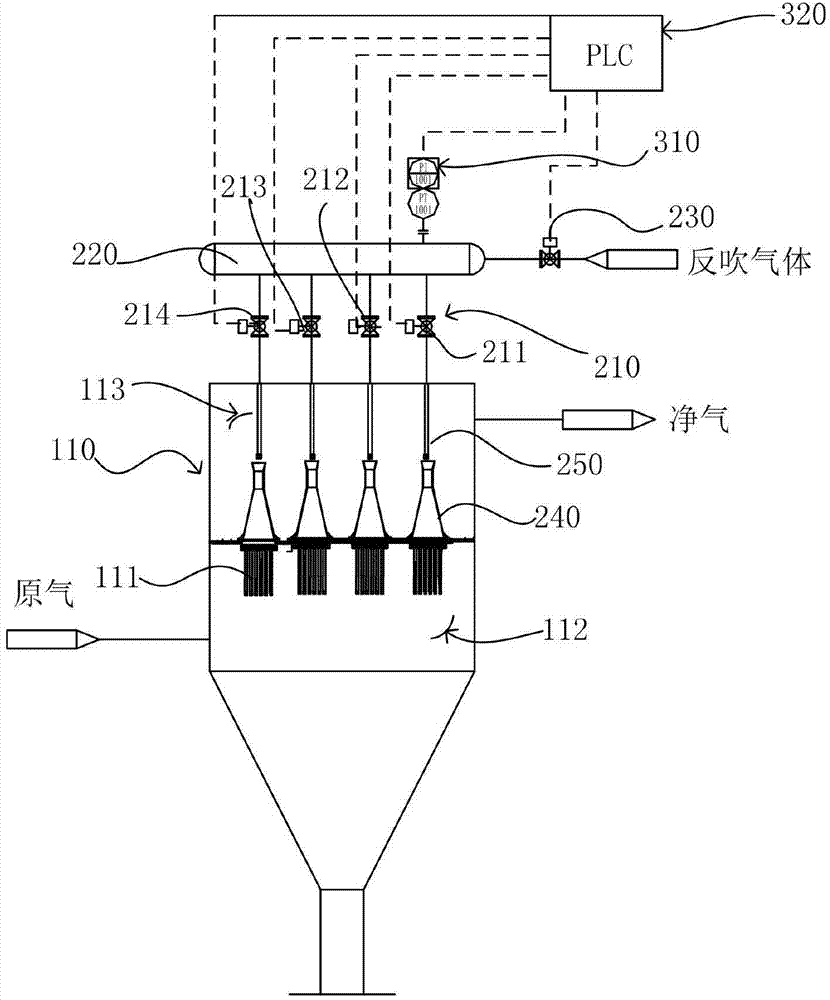

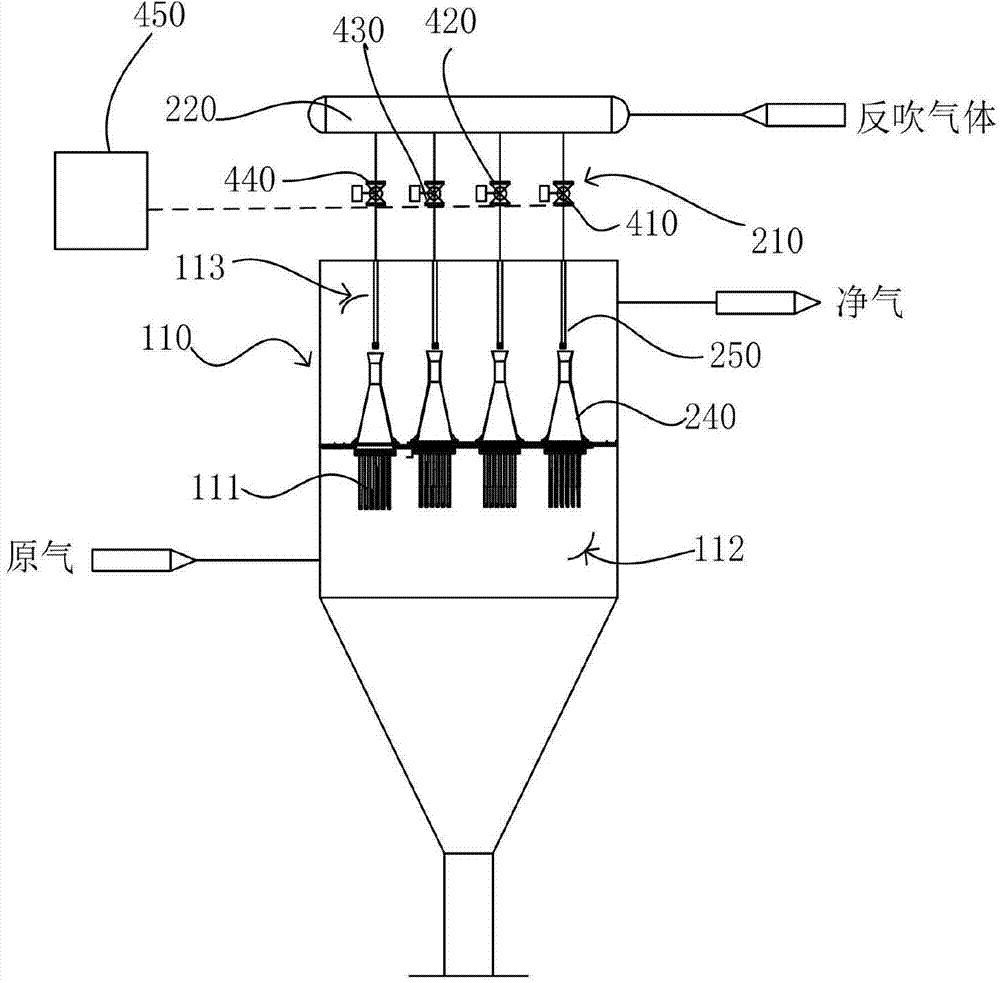

High-temperature reverse blowing process and device thereof

ActiveCN104771964ABackflush pressure requirements are metAvoid job instabilityDispersed particle filtrationEngineeringClosed cavity

Owner:CHENGDU INTERMENT TECH

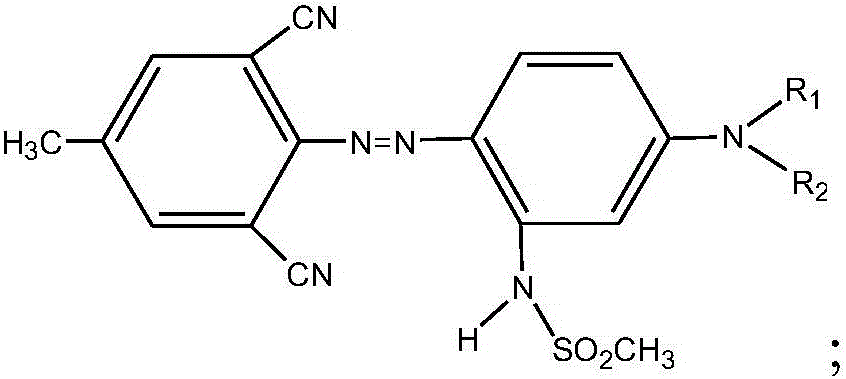

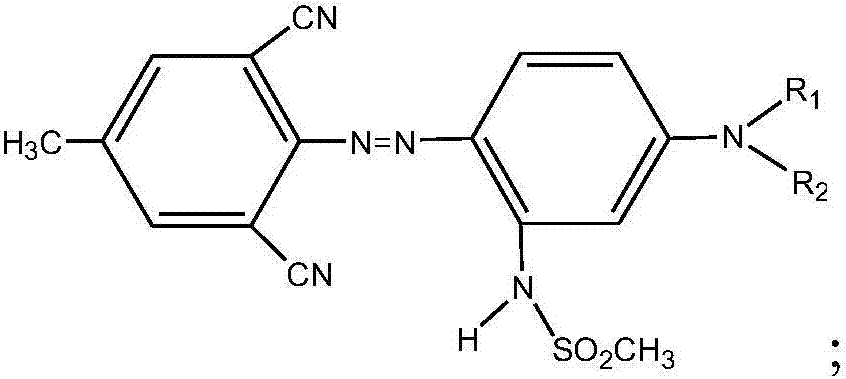

Disperse dye composition used for cellulose triacetate fibers

ActiveCN106317957ASolve the problem of not being able to withstand high temperatureImprove dyeing effectOrganic dyesDyeing processDisperse dyeChemical reaction

The invention discloses a disperse dye composition used for cellulose triacetate fibers, particularly relates to a disperse dye composition without a chemical reaction and belongs to the field of dye. The dye part of the disperse dye composition comprises, by mass, 1-45 parts of component A, 1-35 parts of component B, 25-75 parts of component C and 0.1-2 parts of component D. When the disperse dye composition used for cellulose triacetate fibers is adopted for dyeing, a navy dyed fabric which is beautiful in color, good in fastness to rubbing and excellent in light fastness and other fastness can be obtained; in this way, the disperse dye composition is economic and environmentally-friendly disperse red dye which has excellent dyeing performance.

Owner:上海贝通色彩科技有限公司

A high-temperature resistant wax anticorrosion material

InactiveCN106633268ASolve the problem of not being able to withstand high temperatureOvercoming ingredients are easy to loseWaxSulfonate

A high-temperature resistant wax anticorrosion material is disclosed. The anticorrosion material is prepared from, by mass, 3-70% of polyethylene wax, 5-20% of polytetrafluoroethylene modified polyethylene wax, 0.5-4.5% of 2,6-bis(1,1-dimethylethyl)-4-methylphenol, 5-25% of white oil, 2-3% of petroleum sodium sulfonate, 1.5-10% of fumed silica, and 0.1-0.5% of polysiloxane. The anticorrosion material can overcome the problem that other flexible anticorrosion materials cannot resist high temperatures, and overcomes a problem that petrolatum type anticorrosion materials are prone to component loss and volatilization. The process and operation are simple. The anticorrosion material is prone to industrial production.

Owner:斯耐克(天津)防腐科技有限公司

Electrical connector and production method thereof

ActiveCN103001099ASolve the problem of not being able to withstand high temperatureSimple processContact member assembly/disassemblySecuring/insulating coupling contact membersElectrical connectionElectrical connector

The invention discloses an electrical connector and a production method thereof. At least one electricity conductive layer is plated in a plurality of sheltering holes because the holes are opened on an insulating body; the insulating body is arranged on a circuit board firstly to enable the electricity conductive layer to be in a conductive connection with the circuit board; and then a plurality of electricity conductive rubber blocks are arranged into the sheltering holes correspondingly so as to be electrically connected with the electricity conductive layer. Thus, the plated insulating body is welded fixedly to the circuit board, then the electricity conductive rubber blocks which replace the existing metal stamping terminals are arranged into the insulating body, so that the problem that the electricity conductive rubber is not resistant to high temperature can be solved, the technology is simple, and the cost is reduced.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

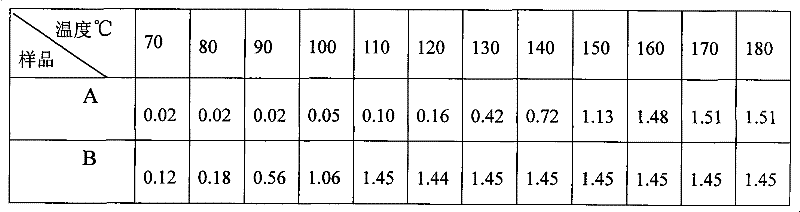

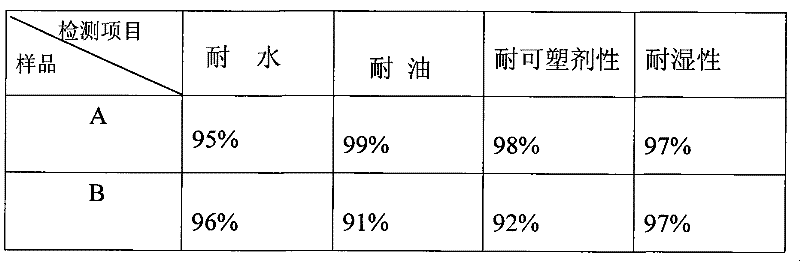

High temperature resistant thermosensitive paper

Disclosed is high temperature resistant thermosensitive paper, a precoating is applied on the original thermosensitive paper; hollow ball resin is added in the precoating paint, a chromogenic layer is applied on the paper with the precoating; and a protective layer is applied on the paper with the chromogenic layer. The chromogenic layer comprises leuco dye, oxidant, sensitizer, lubricant, adhesive, filling calcining soil and anti-aging preparation. The protective layer is acrylamide and epichlorohydrin. In the novel thermosensitive paper process, color development occurs at 180 DEG C, and the bottom color occurs at 150 DEG C so as to solve the problem that common thermosensitive paper does not resist high temperature.

Owner:HENAN JIANGHE PAPER +1

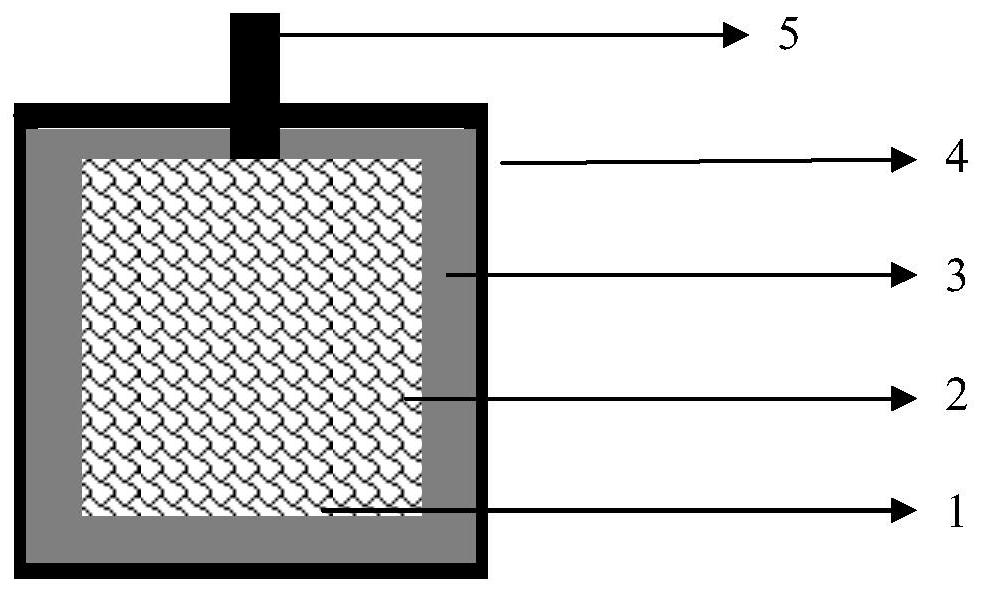

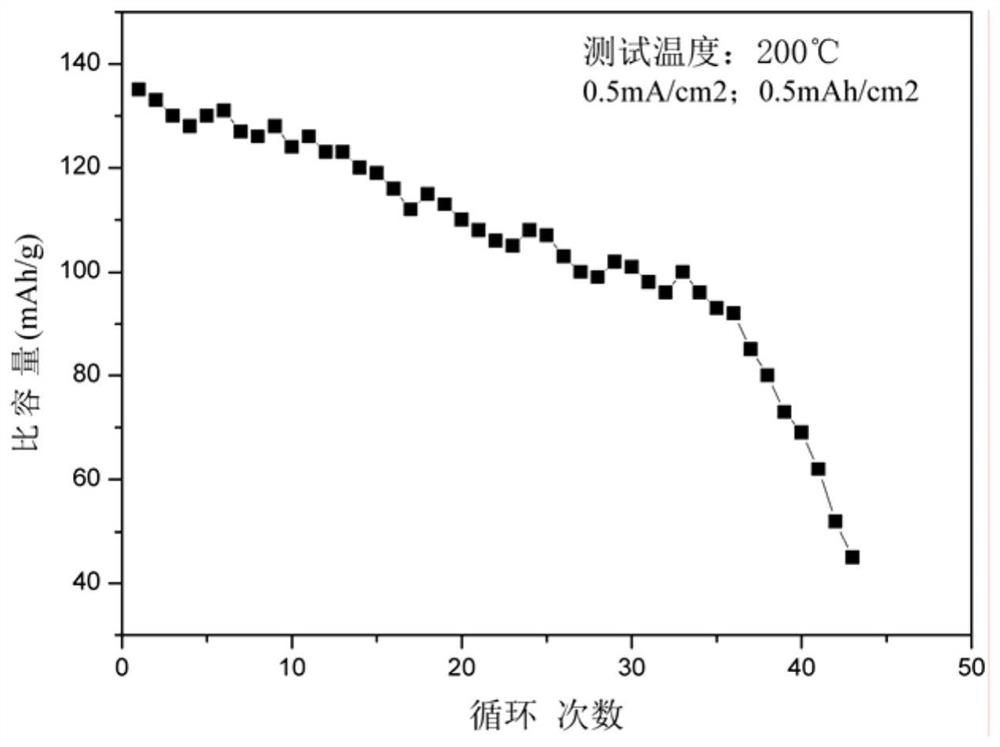

High-temperature-resistant metal lithium negative electrode as well as preparation method and application thereof

ActiveCN113193172AWill not damage the structureSolve the problem of not being able to withstand high temperatureFuel and primary cellsPrimary cellsSolid state electrolyteMetallic lithium

The invention discloses a high-temperature-resistant metal lithium negative electrode as well as a preparation method and application thereof. The high-temperature-resistant metal lithium negative electrode comprises a metal lithium core, a tab in contact with the metal lithium core; a packaging layer used for packaging the metal lithium core, the packaging layer comprising a porous protection layer and an external packaging layer, wherein the porous protection layer is made of a high-temperature-resistant material and is used for packaging all structures, except a tab contact part, of the metal lithium core; and the external packaging layer is a solid electrolyte layer and is formed on the surface, opposite to the main surface of the metal lithium core, of the porous protection layer, or is formed on the whole outer surface of the porous protection layer. The high-temperature-resistant metal lithium negative electrode solves the problem of melting failure of a conventional metal lithium negative electrode at a high temperature, and by using the metal lithium negative electrode disclosed by the invention, even in a working environment exceeding a melting point of metal lithium, the high-temperature-resistant metal lithium negative electrode can still execute functions of the negative electrode without damaging a battery structure and causing failure of the battery.

Owner:CHINA ENERGY LITHIUM

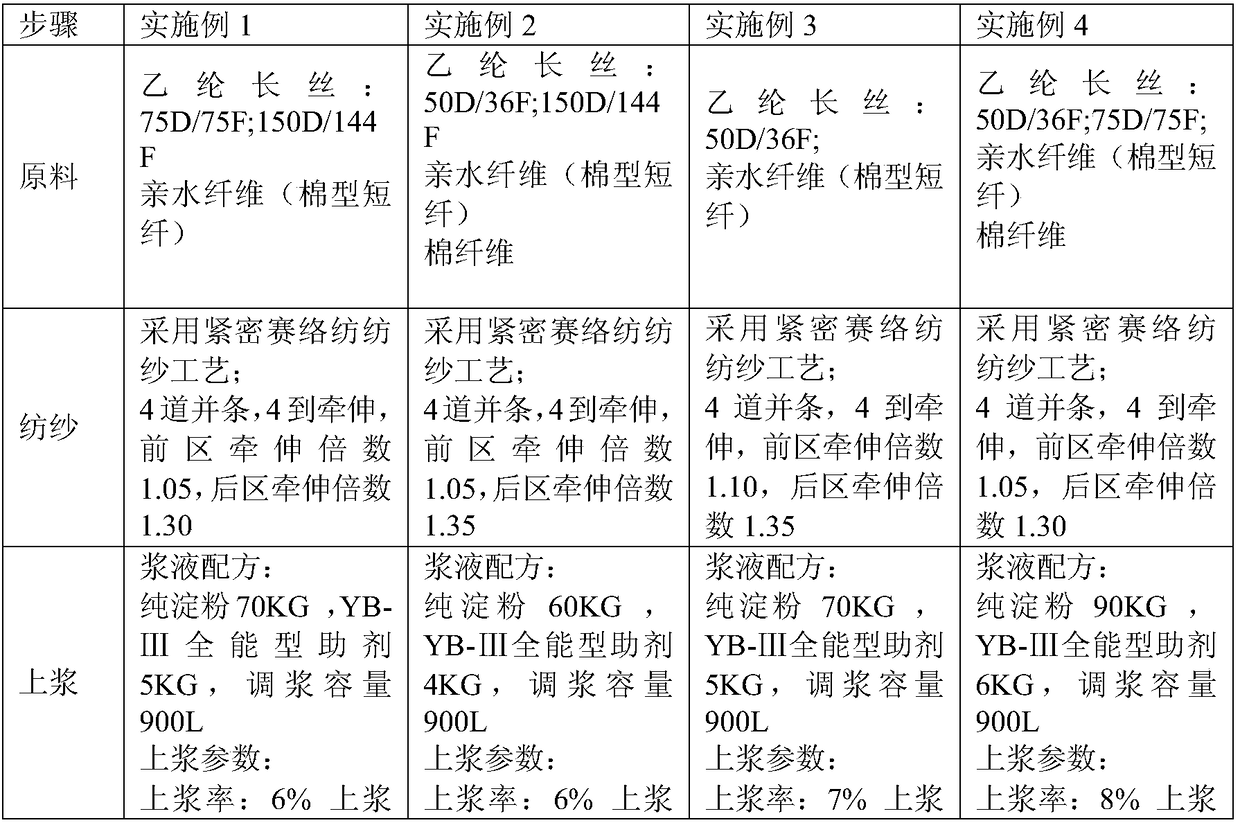

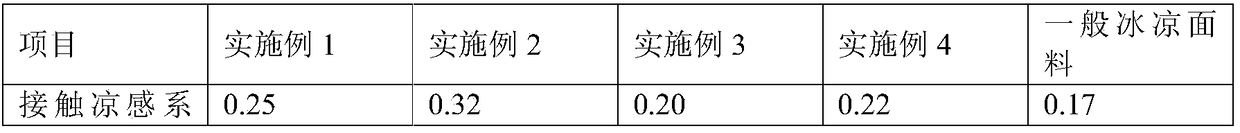

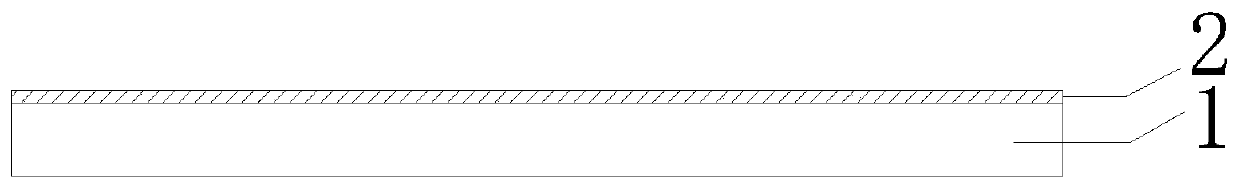

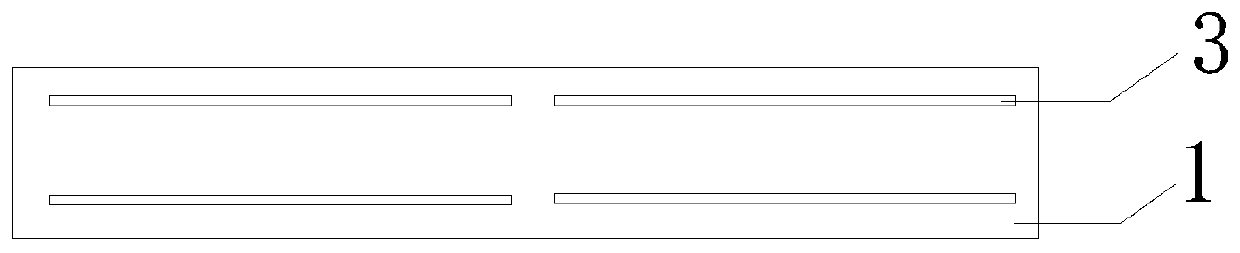

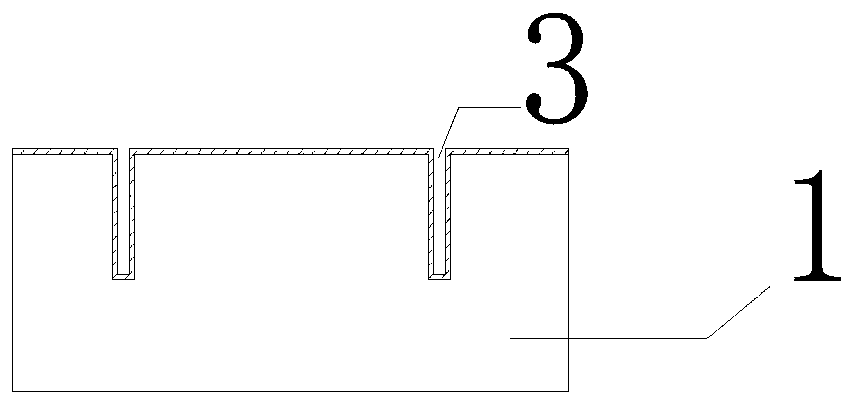

Ice-cold polyethylene fiber wash-and-wear shirt fabric and processing method thereof

InactiveCN109056146ASolve the problem of not being able to withstand high temperatureCool to touchSucessive textile treatmentsDry-cleaning apparatus for textilesCellulose fiberEngineering

The invention relates to the field of textile fabric production, in particular to ice-cold polyethylene fiber wash-and-wear shirt fabric and a processing method thereof. The ice-cold polyethylene fiber wash-and-wear shirt fabric is formed by spinning, starching, fabric weaving, desizing, singeing, dyeing and sizing, wherein spinning comprises the step that one or more of cellulosic fibers are selected to blend with one or more of medium-and-low-temperature dyed synthetic fibers to serve as warp yarn, and the fabric is woven by the warp yarn and polyethylene fiber filaments as weft yarn. According to the above dyeing scheme, the ice-cold polyethylene fiber wash-and-wear shirt fabric has good cool contact sense, moisture absorption, sweat releasing performance and comfort.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Solder strip for IBC photovoltaic module

PendingCN111477713ASolve the problem of not being able to withstand high temperatureMinimizes the problem of easy breakagePhotovoltaic energy generationSemiconductor devicesSlurryVacuum evaporation

The invention aims at disclosing a solder strip for an IBC photovoltaic module. The solder strip comprises a base material and a coating covering the surface of the base material, wherein stress buffer grooves are formed in the base material and distributed in the length direction and the width direction of the base material. Compared with the prior art, the solder strip of the invention has the following characteristics that the coating is made of three materials of Sn, Bi and Pb, the melting point is 160-180 DEG C, low-temperature welding can be achieved, good tensile force is achieved, andthe problem that insulating slurry of an IBC battery is not resistant to high temperature is solved; the stress buffer groove is formed in the base material, and low-temperature welding is adopted, sothat the problem that the IBC battery is easy to crack due to stress concentration during welding can be effectively reduced; and a vacuum evaporation method is adopted to plate a coating, so that the film forming speed is high, the quality is high, the thickness can be accurately controlled, and the purpose of the invention is achieved.

Owner:SPIC XIAN SOLAR POWER CO LTD +3

A Strain of Thermostable Bacillus licheniformis Producing α-Amylase

ActiveCN104357357BSolve the problem of not being able to withstand high temperatureBacteriaMicroorganism based processesBacillus licheniformisMicroorganism

A strain of α-amylase-producing thermostable Bacillus licheniformis, which relates to a strain of Bacillus licheniformis. It solves the problem that the existing engineering strains producing α-amylase are not resistant to high temperature. It is Bacillus licheniformis (Bacillus licheniformis) HWyb1401, which is preserved in the General Microorganism Center of China Committee for the Collection of Microorganisms, and the preservation number is CGMCC No.8718. Bacillus licheniformis (Bacillus licheniformis) HWyb1401 of the present invention has high temperature resistance, can survive at 70°C, and metabolizes α-amylase, and the enzyme activity of α-amylase in its fermentation broth at 55°C can reach 70U / mL .

Owner:INST OF MICROBIOLOGY HEILONGJIANG ACADEMY OF SCI

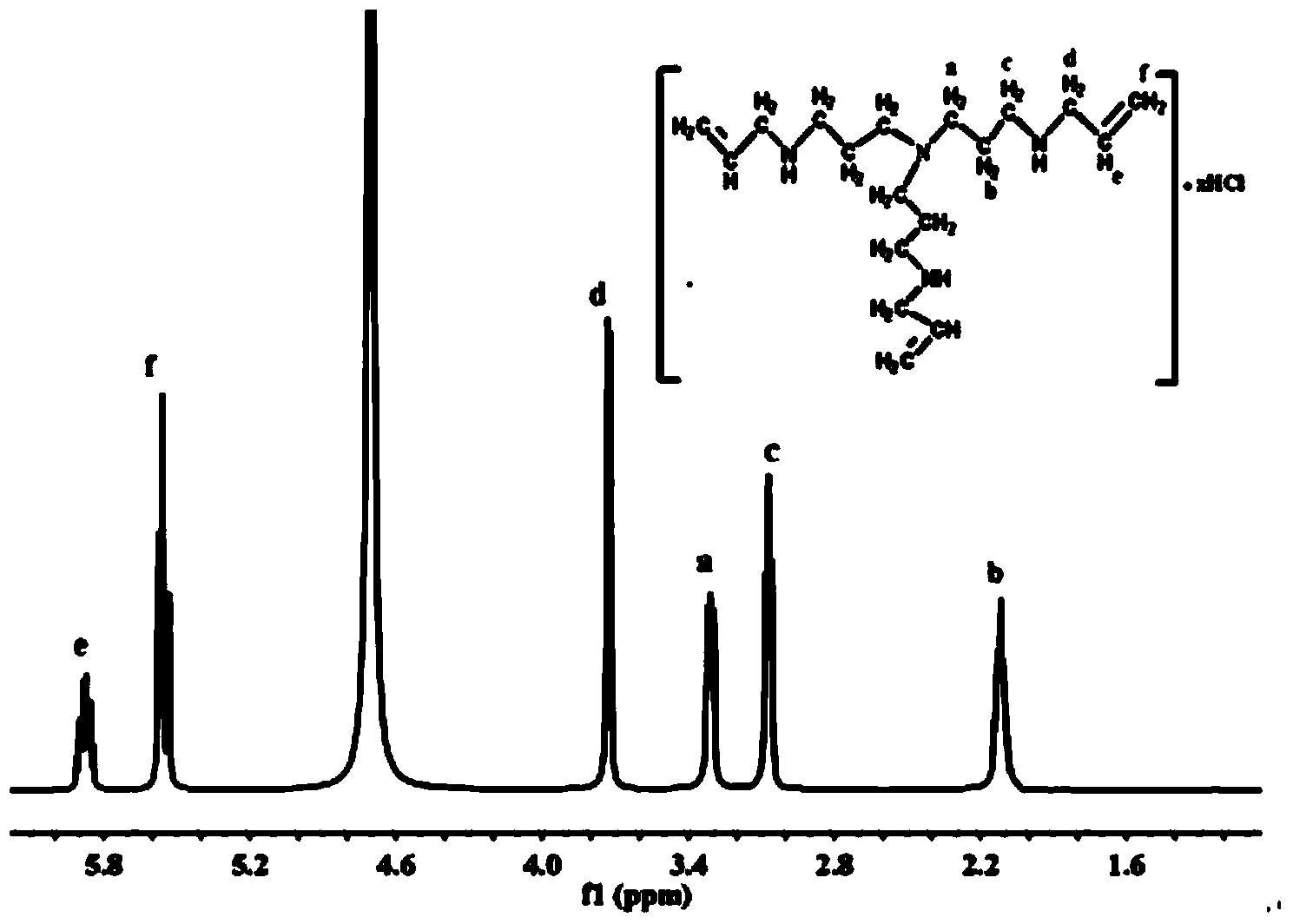

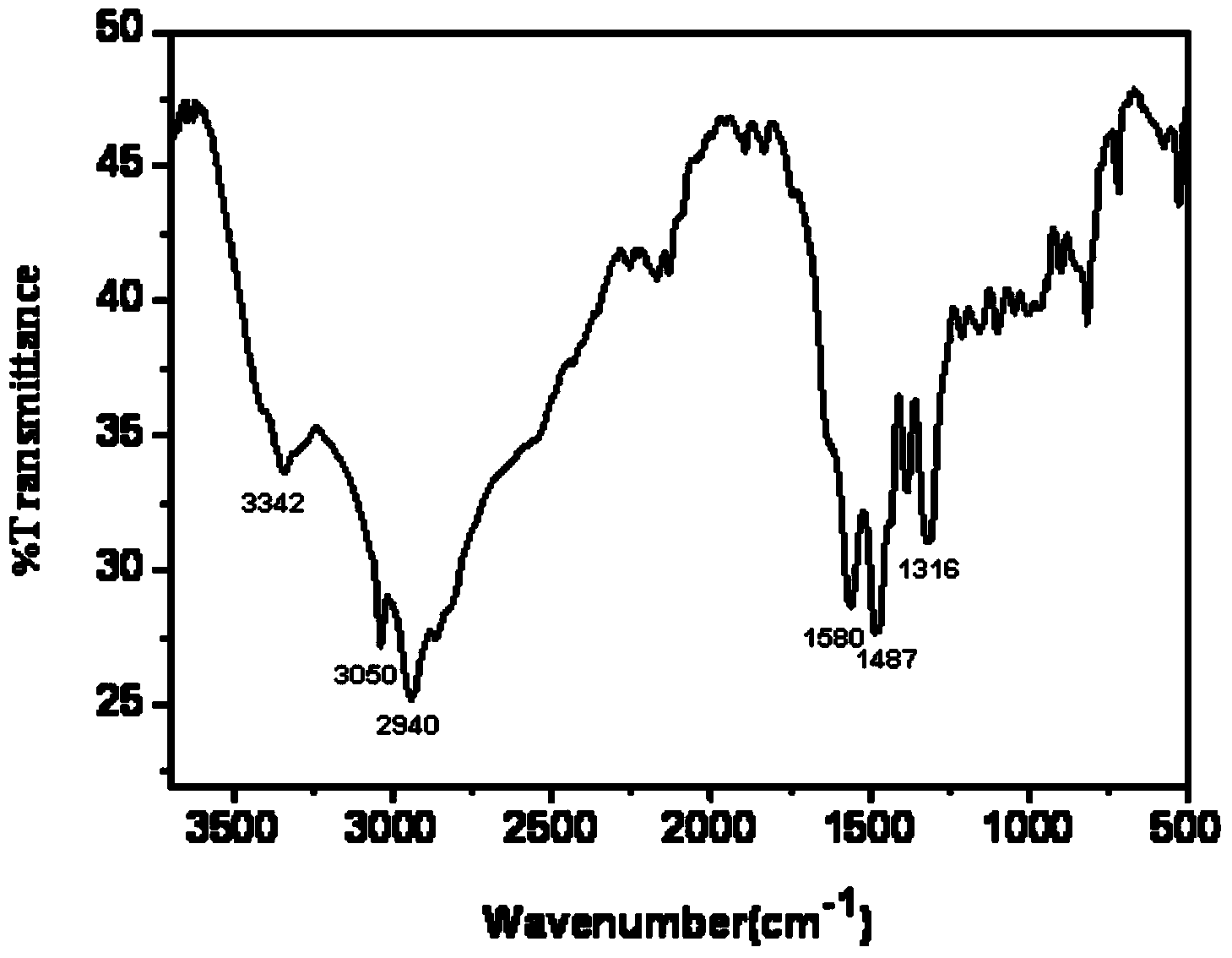

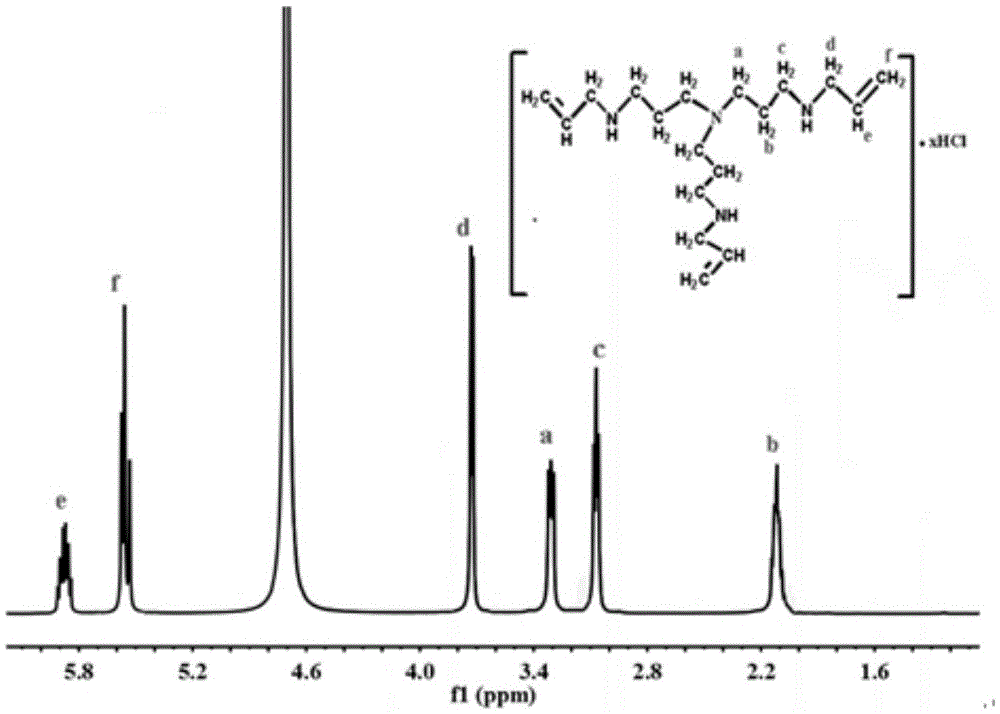

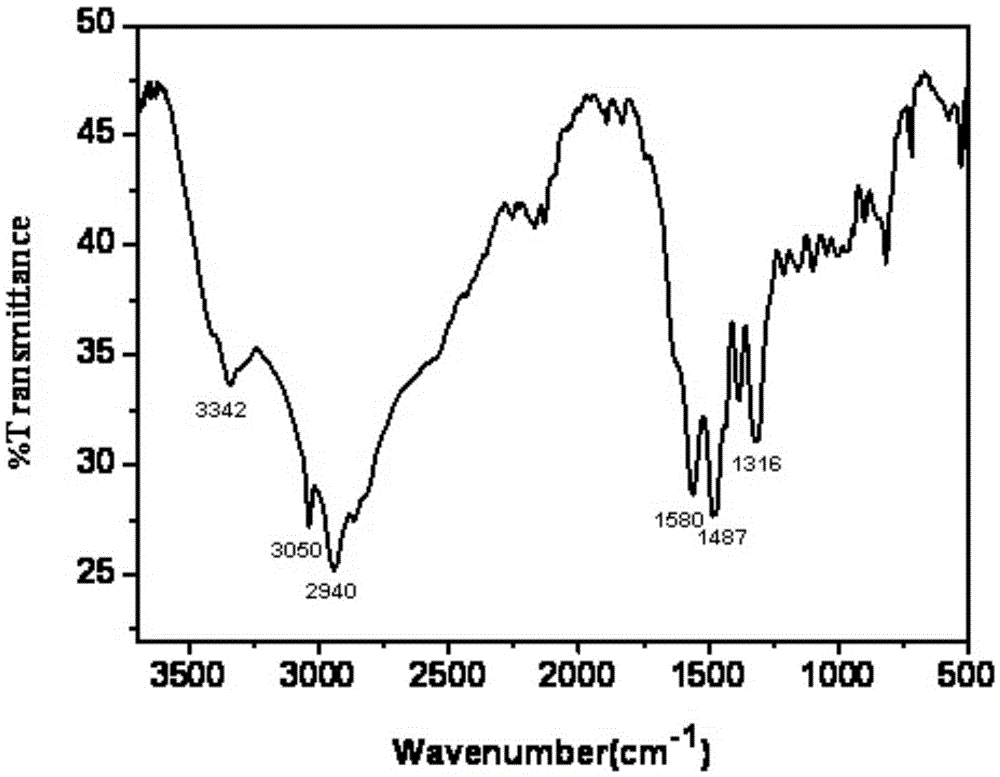

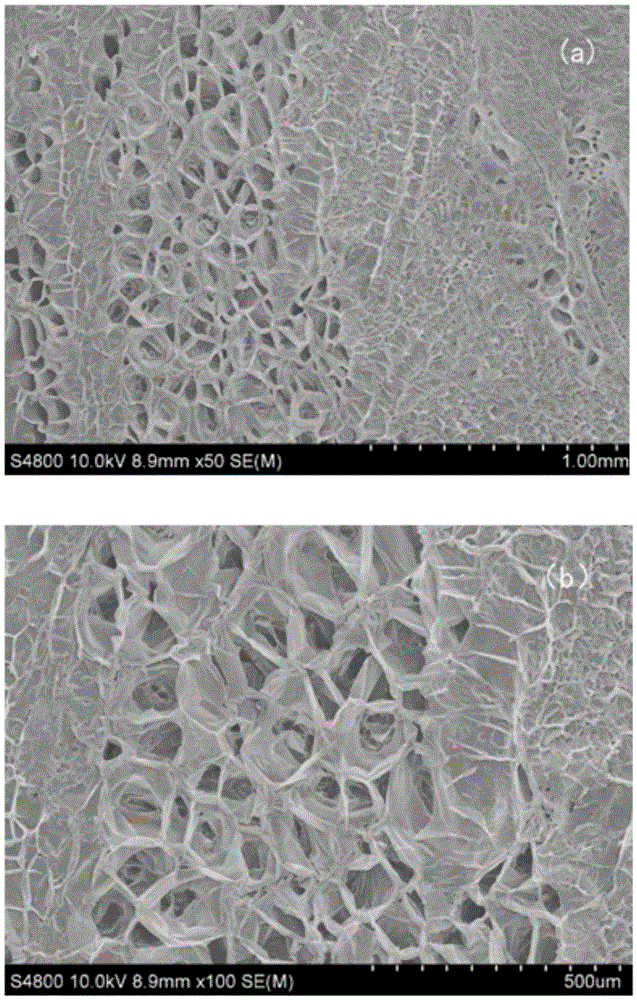

Synthesis method of water-soluble triene cross-linking agent and high-temperature resistant water-absorbing resin

InactiveCN103664632ASolve the problem of not being able to withstand high temperatureSimple processAmino preparation by functional substitutionCross-linkSynthesis methods

The invention discloses a synthesis method of a water-soluble triene cross-linking agent. The synthesis method comprises the following steps: adding triaminopropylamine (trpn), water and cationic surfactant into a reactor, evenly stirring and mixing, controlling the reaction temperature in a range of 30 to 35 DEG C, dropwise adding chloropropene into the reactor within 4 hours, controlling the temperature under 35 DEG C, and keeping on stirring until the solution turns transparent after the adding of chloropropene so as to obtain the triene cross-linking agent. The invention also provides a synthesis method of a high-temperature resistant water-absorbing resin by using the triene cross-linking agent. The synthesis method comprises the following steps: adding a mixed solution of copolymerization monomers and the triene cross-linking agent into a reactor, introducing nitrogen gas for 30 minutes, then adding an initiator, stopping introducing nitrogen gas after 10 minutes, carrying out reactions for 4 hours at a room temperature so as to obtain a reaction product, subjecting the reaction product to an extruding and granulating process, drying the granules at a temperature of 80 DEG C, and finally grinding the dried granules so as to obtain the high-temperature resistant water-absorbing resin. The synthesis method of water-absorbing resin has the advantages of simple process and low energy consumption, the saturated water absorption rate of the resin in distilled water with a temperature of 300 DEG C is 150 to 400 g / g, and the saturated water absorption rate of the resin in a NaCl water solution with a mass percentage of 0.9% is 50 to 130 g / g.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

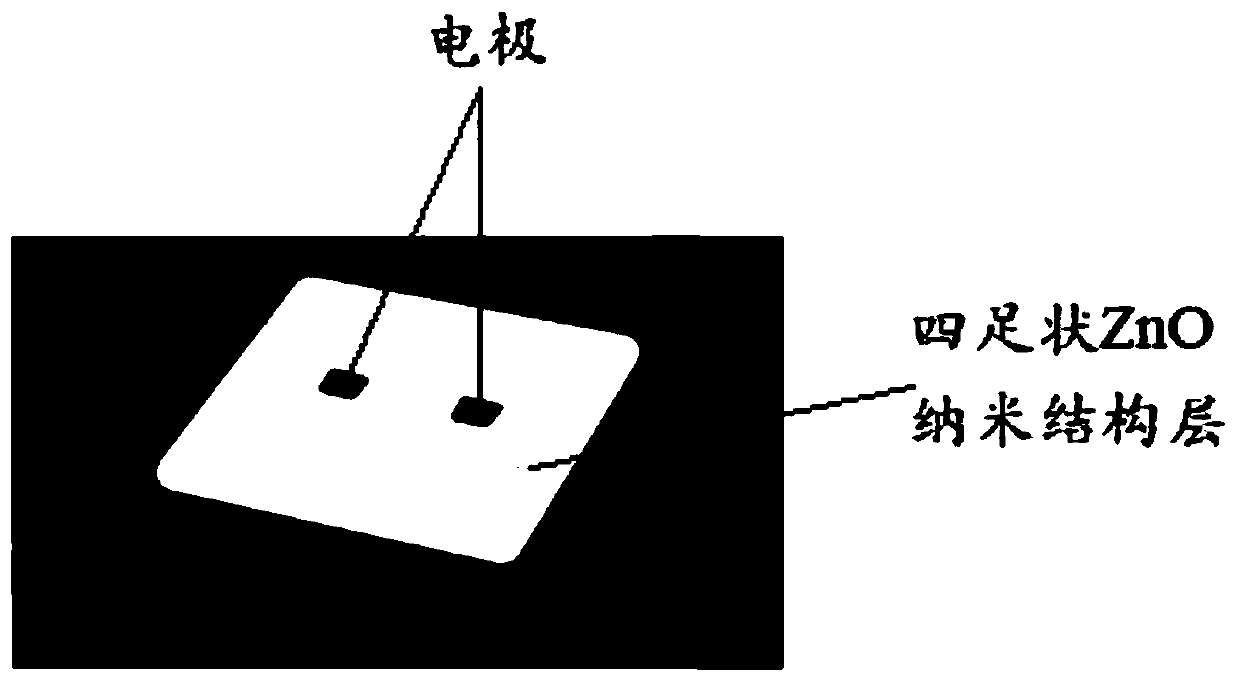

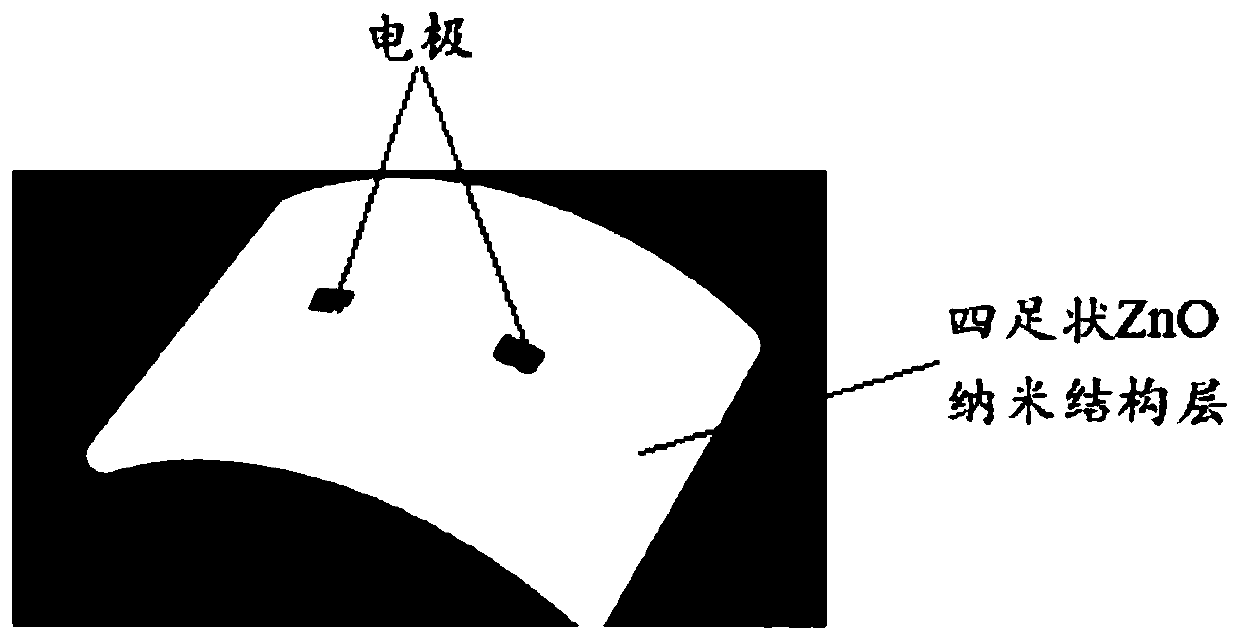

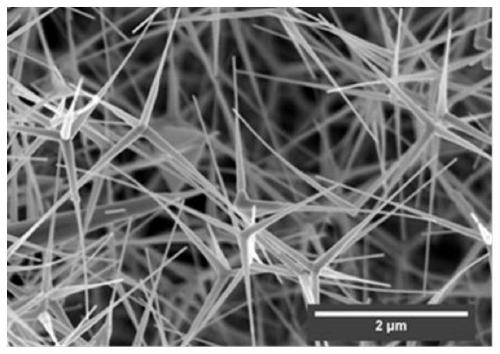

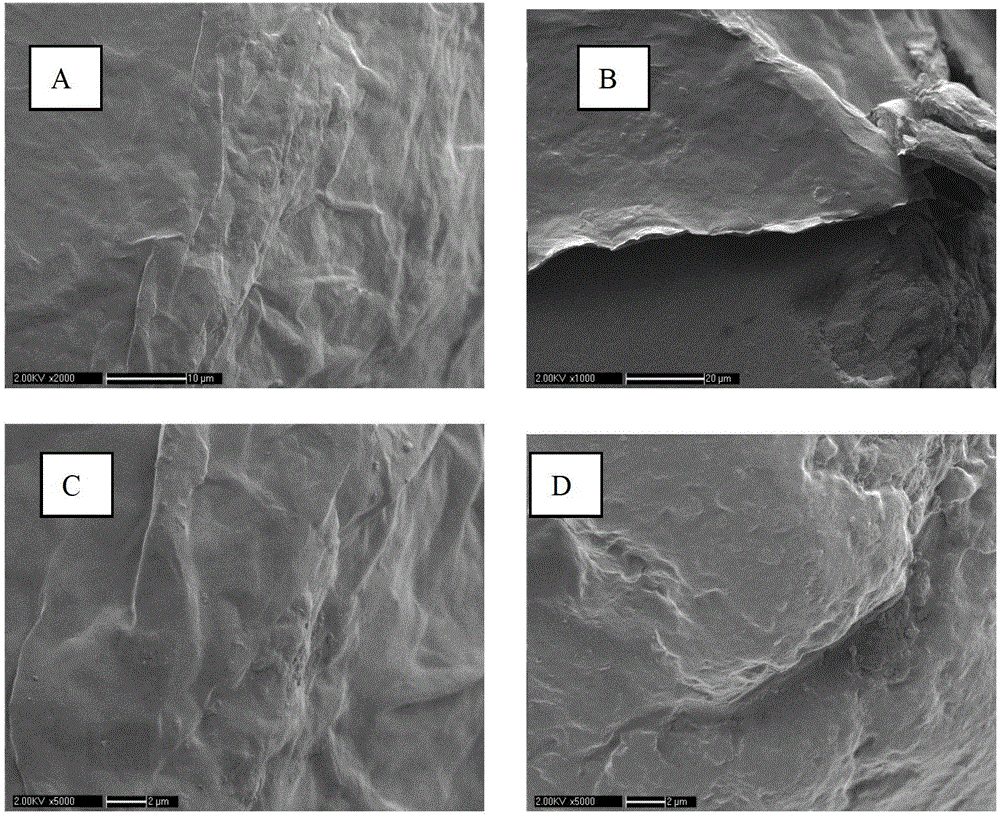

Flexible self-supporting ZnO ultraviolet detector and preparation method thereof

ActiveCN111244201AEasy to prepareSimple manufacturing methodFinal product manufactureSemiconductor devicesUltraviolet detectorsNanowire

The invention provides a flexible self-supporting ZnO ultraviolet detector, which belongs to the technical field of ultraviolet detection. The flexible self-supporting ZnO ultraviolet detector comprises a quadruped ZnO nano-structure layer, two electrodes arranged on the surface of the quadruped ZnO nano-structure layer, and a flexible substrate; and the quadruped ZnO nano-structure layer independently exists to realize self-supporting, and is arranged on the flexible substrate through transfer. The invention also provides a preparation method of the flexible self-supporting ZnO ultraviolet detector. According to the ultraviolet detector, the quadruped ZnO nanostructure layer is adopted, the ultraviolet detector has a special quadruped structure, four nanowires are used as a unit and stacked to form a flocculent self-supporting structure, and the flexible ultraviolet detector with high response speed is simply and efficiently obtained; and the tetrapod-shaped ZnO nano-structure layer is high in crystallization quality, excellent in performance, high in light and dark inhibition ratio and high in response speed, can be applied to manufacturing of a flexible ultraviolet detector, andeffectively solves the problem that a substrate in an existing ZnO micro-nano structure flexible ultraviolet detector is not resistant to high temperature.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Probiotic fresh stewed edible bird's nest and preparation method thereof

InactiveCN110074401ASolve the problem of not being able to withstand high temperatureKeep aliveFood ingredient functionsIntestinal microorganismsSugar

The invention relates to the field of edible bird's nest processing, and particularly relates to a probiotic fresh stewed edible bird's nest and a preparation method thereof. The preparation method ofthe probiotic fresh stewed edible bird's nest comprises using a mixture of agar oligosaccharide and ethyl cellulose, gelatin and starch to embed probiotics to prepare a probiotic microcapsule preparation; specifically, the edible bird's nest is soaked into a soaked edible bird's nest, then the soaked edible bird's nest, the probiotic microcapsule preparation, rock sugar and water are added to a sealed container, and the sealed container is placed in a cooking pot at 85 to 100 DEG C for stewing for 30 to 50 minutes to prepare the probiotic fresh stewed edible bird's nest, thereby reducing theloss of nutrients in the edible bird's nest, solving the problem that the probiotics in the edible bird's nest product is not resistant to high temperature, and realizing the effect of regulating intestinal microbes.

Owner:大洲新燕(厦门)生物科技有限公司

A kind of disperse dye composition for triacetate

ActiveCN106317957BSolve the problem of not being able to withstand high temperatureImprove dyeing effectOrganic dyesDyeing processDisperse dyeChemical reaction

The invention discloses a disperse dye composition used for cellulose triacetate fibers, particularly relates to a disperse dye composition without a chemical reaction and belongs to the field of dye. The dye part of the disperse dye composition comprises, by mass, 1-45 parts of component A, 1-35 parts of component B, 25-75 parts of component C and 0.1-2 parts of component D. When the disperse dye composition used for cellulose triacetate fibers is adopted for dyeing, a navy dyed fabric which is beautiful in color, good in fastness to rubbing and excellent in light fastness and other fastness can be obtained; in this way, the disperse dye composition is economic and environmentally-friendly disperse red dye which has excellent dyeing performance.

Owner:上海贝通色彩科技有限公司

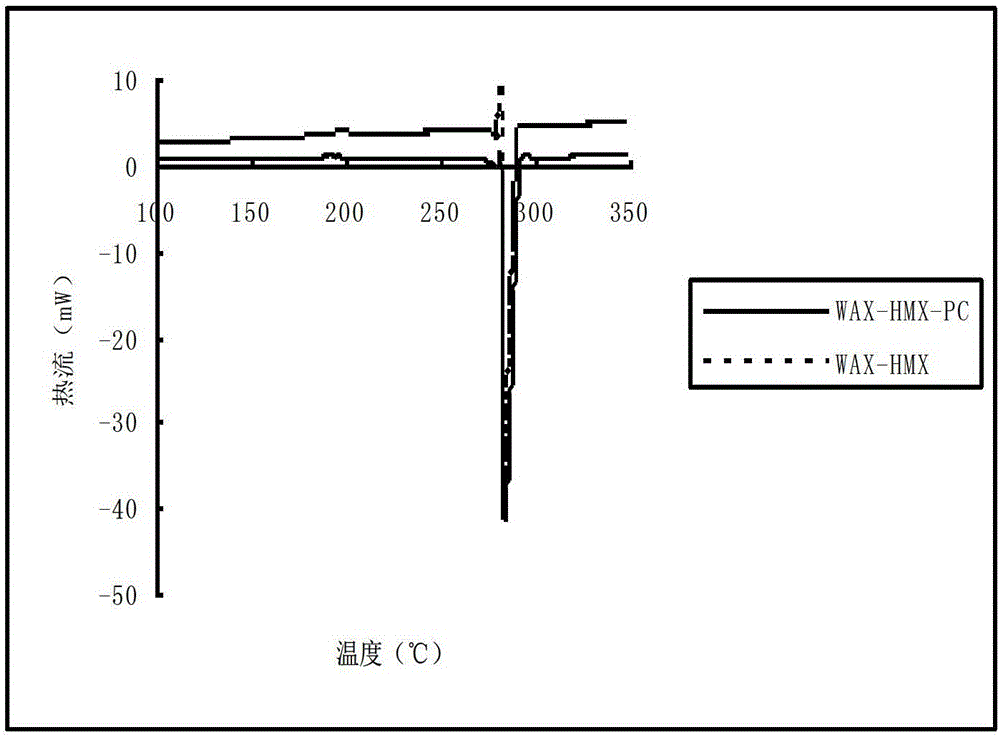

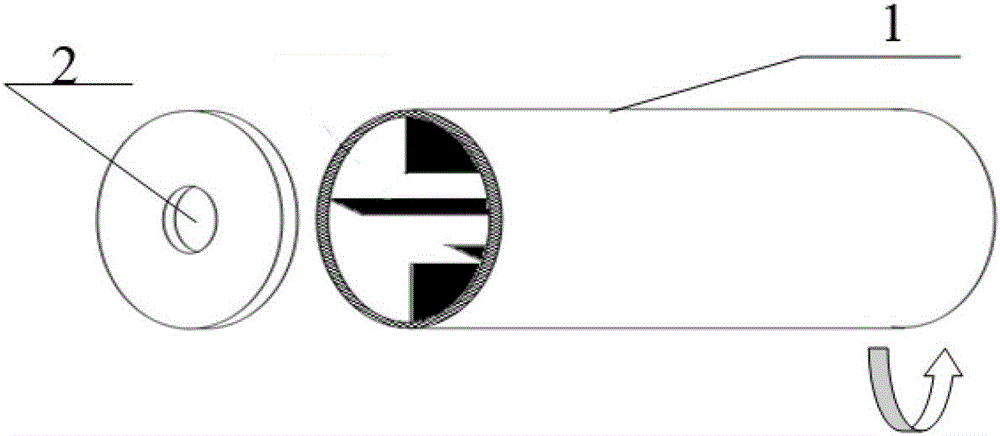

Method for Surface Coating of Explosive Particles

ActiveCN103342619BSolve the problem of not being able to withstand high temperatureStrong high temperature resistanceExplosive working-up apparatusParyleneExplosive cladding

The invention discloses a surface coating method for explosive particles. The surface coating method comprises the following steps of: (1) depositing vapor deposition substances at the surfaces of the explosive particles by utilizing a vacuum physical vapor deposition method, so as to obtain explosives coated by wax; and (2) depositing chemical vapor deposition substances at the surfaces of the explosive particles obtained in the step (1) by utilizing a vacuum chemical vapor deposition method. According to the coating method, the explosive particles are coated by a Parylene film after being coated by the wax, as the Parylene film has relatively strong high temperature resistance and can be used for further coating the explosives coated by the wax, the problem that the explosives coated by the wax cannot resist the high temperature is solved, and the explosive particles coated by the Parylene film after being coated by the wax can be used for casting the explosives or composite explosives.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

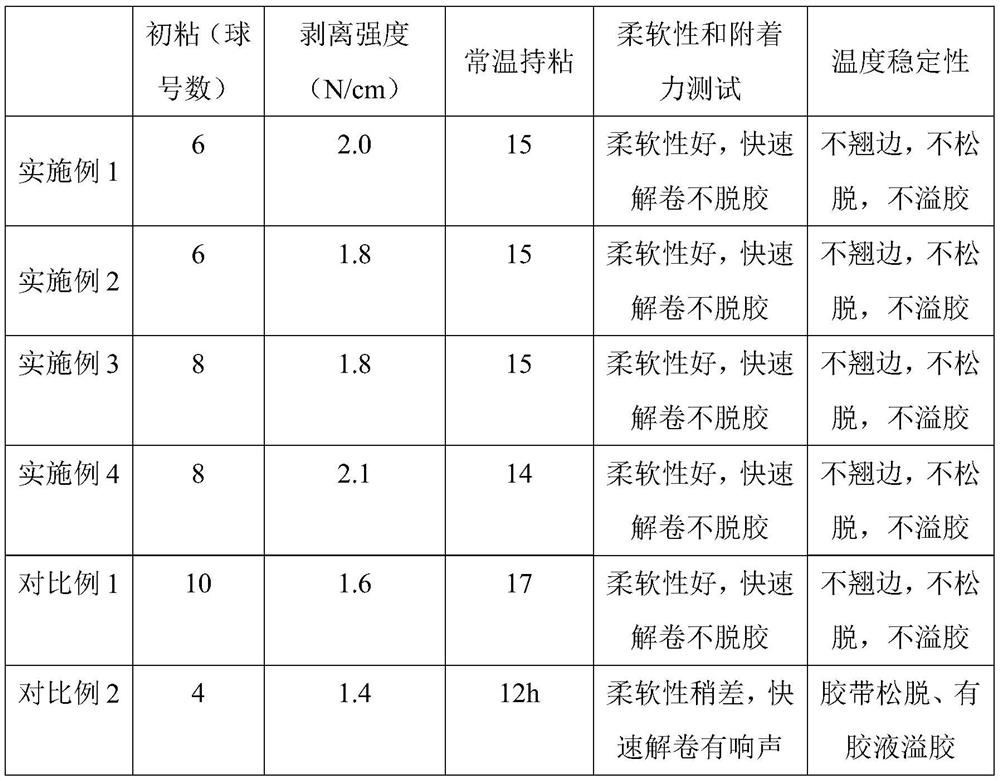

Electron beam curing type hot-melt pressure-sensitive adhesive and application thereof

PendingCN114763456AOvercome the disadvantage of high consumptionSolve the problem of not being able to withstand high temperatureEster polymer adhesivesPolymer scienceFunctional monomer

The invention relates to the field of adhesives, in particular to an electron beam curing type hot-melt pressure-sensitive adhesive and application thereof. The adhesive is prepared from the following raw materials: an allyl monomer and a solvent. The electron beam curing type hot-melt pressure-sensitive adhesive provided by the invention overcomes the defect of high energy consumption caused by solvent type glue coating, and achieves remarkable social benefits in the aspect of production energy conservation. And in the aspects of environmental protection, sanitation and safety, no solvent, zero emission, 100% curing, real no residue, no photoinitiator, no odor and no VOC emission are realized. The problem that water emulsion type glue cannot resist high temperature is solved, and an adhesive tape manufactured by adopting the electron beam curing type hot-melt pressure-sensitive adhesive has a high long-term temperature-resistant grade and can be used in a high-temperature environment. The adhesive is prepared by using a soft monomer and a functional monomer in a certain weight ratio as alkene monomers, and through electron beam curing, high high-temperature stability can be obtained, and high adhesive force and initial adhesion performance are ensured while the flexibility of an adhesive product is improved.

Owner:亮线上海新材料科技有限公司

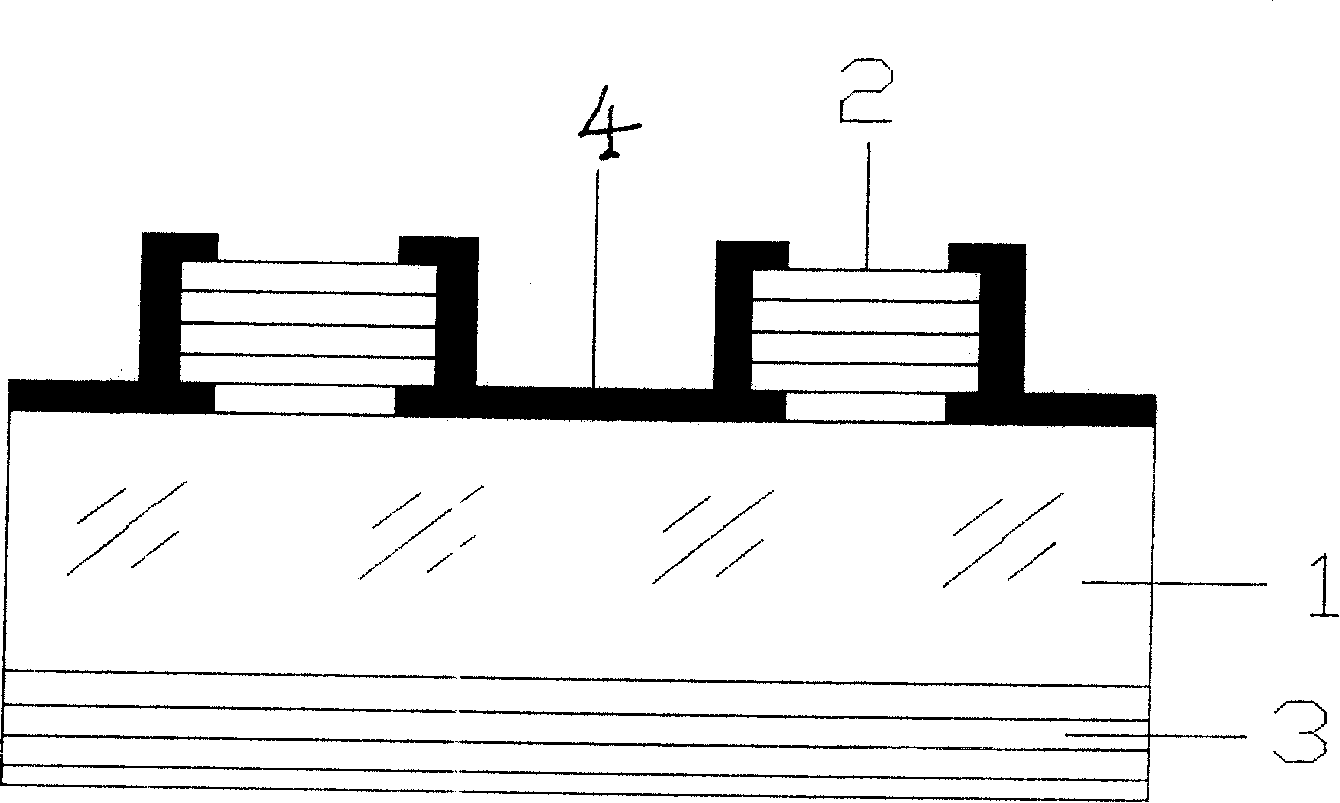

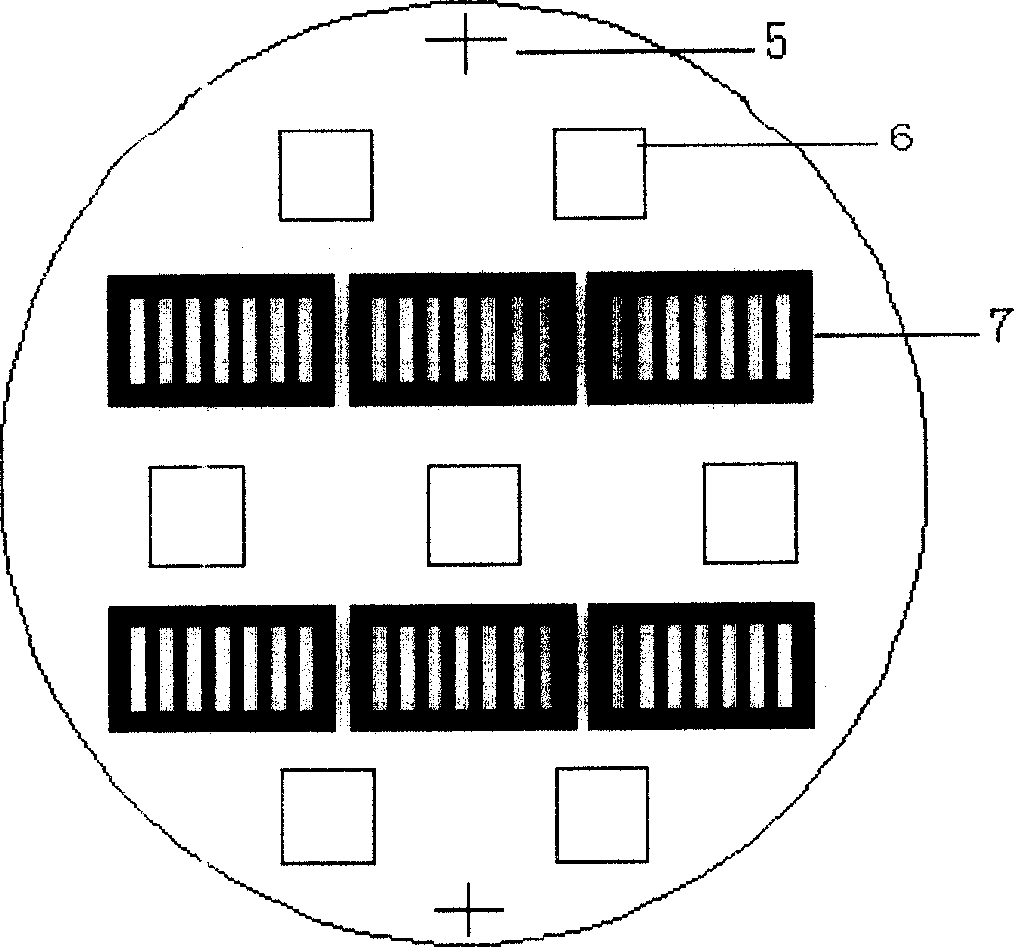

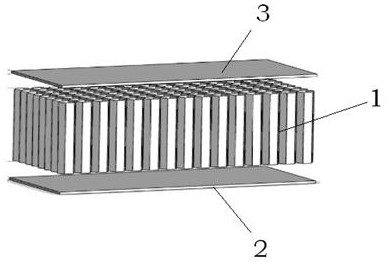

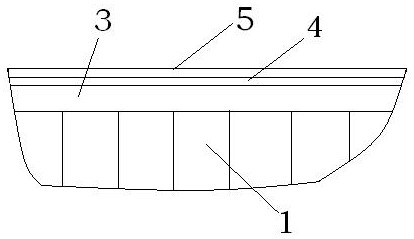

Micro-integrated narrow-band filter array and preparing method thereof

ActiveCN100385268CCrosstalk EliminationHigh transfer functionOptical filtersPhotomechanical apparatusLight filterCrosstalk

The present invention discloses a micro type integrated narrow-band filter array and its preparation method. Said filter array includes the following several portions: a substrate, on one side surface of said substrate several channel micro type narrow-band light-filtering film layers are firmly combined, on its another side surface a common section subpeak film layer is coated. It is characterized by that between every two channel micro type narrow-band light-filtering film layers a space layer is set, in the space layer interior a light-proof metal layer capable of preventing light crosstalk is set. Besides, said invention also provides the concrete steps of its preparation method.

Owner:上海欧菲尔光电技术有限公司 +2

High-temperature thermal transfer printing decoration method and product of wear-resistant aluminum honeycomb panel for interior decoration of rail transit

ActiveCN109291675BSolve the problem of not being able to withstand high temperatureImprove the decorative effectDecorative surface effectsDuplicating/marking methodsAluminum honeycombSpot welding

The invention relates to a high-temperature thermal transfer decoration method for an abrasion-resistant aluminum honeycomb panel of rail transit interior decoration and a product. A honeycomb panel core of the aluminum honeycomb panel and two panels are combined and welded through spot welding and brazing to form the high-temperature resistant aluminum honeycomb panel; the surface of the aluminumhoneycomb panel is pretreated, then a layer of resin base powder is sprayed to the surface of the aluminum honeycomb panel through high voltage static, and the resin base powder is cured at the hightemperature being 210 to 280 DEG C; after the resin base powder is cured, woodgrained paper is pasted to the resin base powder; and then the aluminum honeycomb panel provided with the woodgrained paper in a pasted manner is placed into an oven for high-temperature thermal transfer at 210-260 DEG C, so that the surface of the aluminum honeycomb panel has the effect of natural wood grains, and the decoration effect the same as that of natural wood is achieved.

Owner:株洲九方因赛德技术有限公司

A kind of synthetic method of water-soluble triene crosslinking agent and high temperature resistant water-absorbent resin

InactiveCN103664632BSolve the problem of not being able to withstand high temperatureSimple processAmino preparation by functional substitutionCross-linkSynthesis methods

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Multifunctional cable

InactiveCN107134310AImprove high temperature resistanceEnsure safetyInsulated cablesInsulated conductorsPolypropylenePolyacrylamide

The invention discloses a multifunctional cable, which includes a conductor layer, the conductor layer includes at least one conductor, an insulating layer is arranged on the outer layer of the conductor layer, the insulating layer is glass fiber, and the insulating layer is The outer layer is provided with an anti-bite layer, and the outer layer of the anti-bite layer is provided with a high temperature resistant layer, and the anti-bite layer is composed of the following components by weight: 80-100 parts by weight of silicone rubber, polyaryl boron 12-25 parts by weight, 10-15 parts by weight of inorganic filler, 8-10 parts by weight of hydroxy silicone oil, 1-3 parts by weight of vulcanizing agent; the high temperature resistant layer is composed of the following parts by weight: ethylene and its polymer 20- 30 parts by weight, 80-100 parts by weight of thermoplastic elastomer, 10-15 parts by weight of polypropylene, 50-60 parts by weight of flame retardant, 12-18 parts by weight of polyacrylamide, and 10-20 parts by weight of crosslinking agent. The invention solves the problems that the existing cables are easily eaten by mice and are not resistant to high temperature.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Method for manufacturing ceramic-based interconnected rigid flexible combined multilayer circuit board

InactiveCN101990373BSolve the problem that it is difficult to achieve interlayer conduction through electroplatingSolve the problem of not being able to withstand high temperatureMultilayer circuit manufactureEpoxyResist

The invention discloses a method for manufacturing a ceramic-based interconnected rigid flexible combined multilayer circuit board, which is characterized by comprising the following steps of: A. manufacturing an aluminum nitride ceramic circuit board; B. manufacturing a flexible circuit board; C. manufacturing an epoxy resin circuit board; D. laminating the aluminum nitride ceramic circuit board, the flexible circuit board and the epoxy resin circuit board; E. manufacturing a through hole passing through the upper surface and the lower surface of the multilayer board on the multilayer board obtained in the step D by adopting laser drilling equipment, processing the hole with a conducting material, then drying to obtain a through hole; F. printing solder resist ink in positions on the multilayer board, at which electronic elements do not need to be welded; G. silk printing characters in preset positions on the multilayer board; and H. cutting the circuit board into predetermined specifications by adopting laser cutting equipment to obtain the ceramic-based rigid flexible multilayer circuit board. The invention provides the manufacturing method of the ceramic-based interconnected rigid flexible combined multilayer circuit board with simple process, high wiring density, good 3D connection performance and good thermal conductivity.

Owner:广东达进电子科技有限公司

Fabric shaping/dryer energy conservation and emission reduction control system and method for textile and dying industry

ActiveCN103184667BSolve the problem of not being able to withstand high temperatureImprove printing and dyeing effectTextile treatment machine arrangementsExhaust valveControl signal

An embodiment of the invention discloses a fabric shaping / dryer energy conservation and emission reduction control system for the textile and dying industry. The control system comprises a sampling unit, a radiating unit, a detection module, a data processing control unit, a control unit, a display unit and a setting unit, wherein the sampling unit obtains sampling gas, and the sampling gas is cooled by the radiating unit; the data processing control unit compares values, detected by a humidity sensor and / or a smoke sensor, of the cooled sampling gas with a set value; and a control signal is output to control the opening degree of an exhaust valve, so that exhaust operation is performed. The embodiment of the invention further discloses a clothes shaping and drying energy conservation and emission reduction control method. When the control system and method are adopted, the problem that the humidity sensor or the smoke sensor are not high temperature resistant is solved, the detection values of the humidity sensor and / or the smoke sensor are chosen to be compared with a set value according to different technologies, and the opening degree of the exhaust valve is controlled, so that optimal working parameters are maintained, and a large amount of energy is avoided from being consumed by exhaust by mistake.

Owner:李川凌

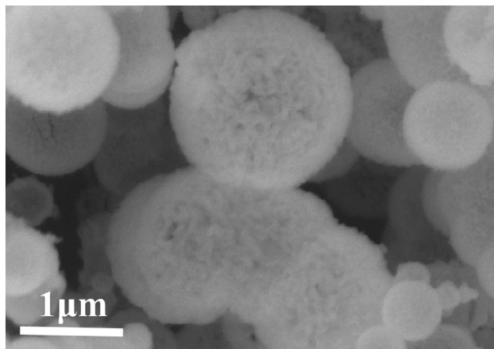

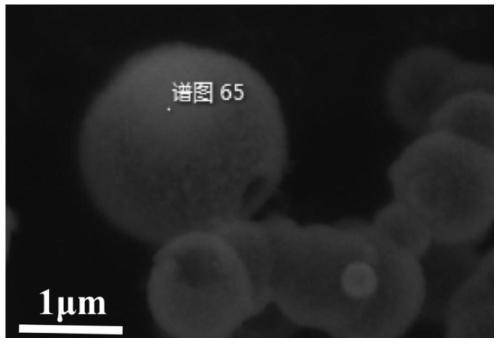

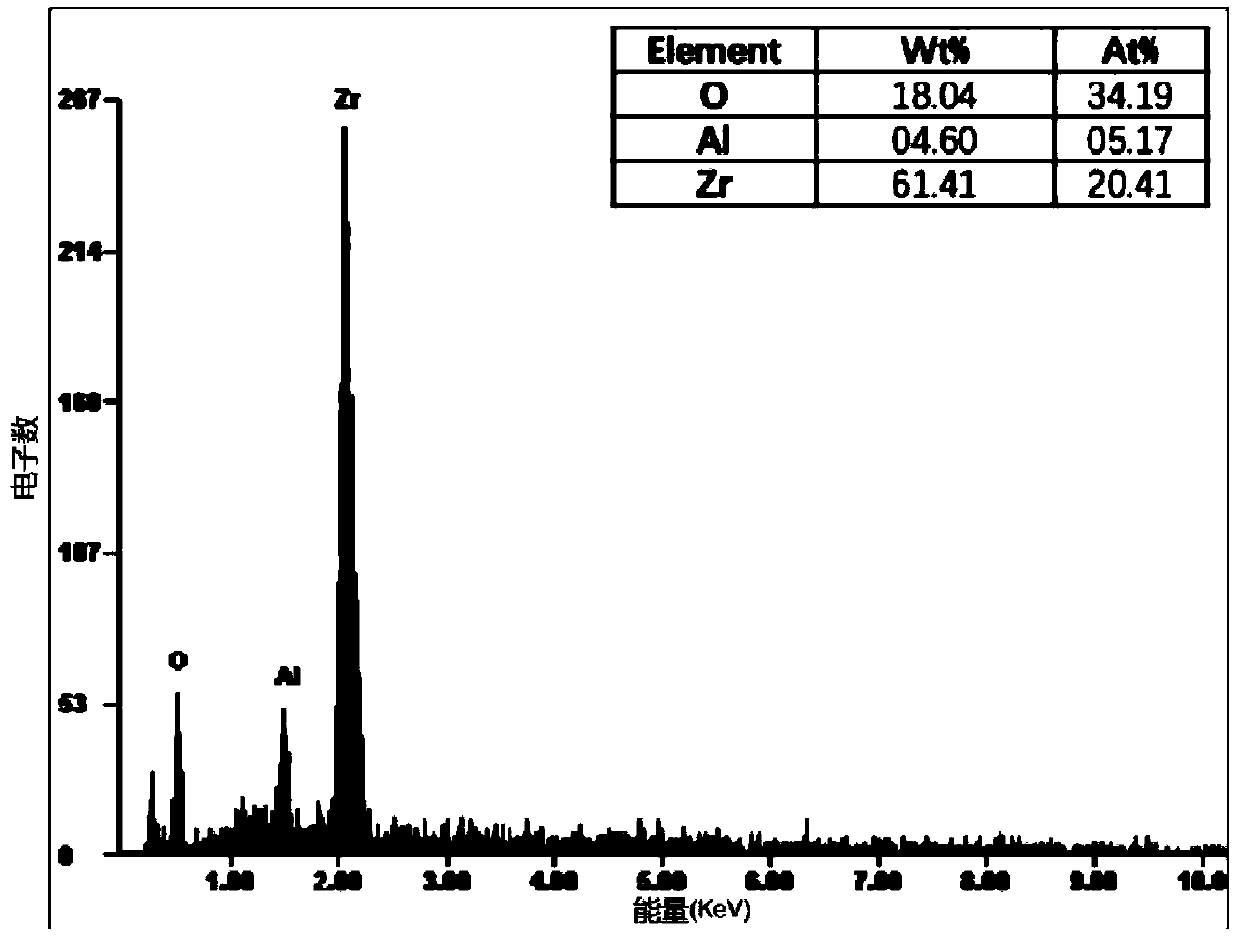

Aluminum-containing zirconia hollow microspheres and preparation method thereof

ActiveCN108640151BReduced diffusion rateSolve the problem of not being able to withstand high temperatureZirconium oxidesMicrospherePhysical chemistry

The invention discloses an aluminum-containing zirconia hollow microsphere. The aluminum-containing zirconia hollow microsphere comprises an aluminum element and a zirconium element in a molar ratio of (1-4):8, and the diameter of the aluminum-containing zirconia hollow microsphere is 0.1 to 10 mu m. The invention also discloses a method for preparing the aluminum-containing zirconia hollow microsphere, comprising the following steps: uniformly mixing an aluminum precursor, a zirconium precursor, urea and strong acid in ethanol to form a clear solution; placing the clear solution in a closed reaction kettle, performing solvothermal reaction at 160 to 200 DEG C for 6 to 18 hours, cooling, collecting white precipitates in the product, and performing washing and drying; calcining at 800 to 1000 DEG C for 1 to 4 hours. In the invention, the aluminum element is introduced into the zirconia hollow microsphere to effectively reduce the diffusion rate of zirconia at high temperature, so that the hollow microsphere is kept stable above 1300 DEG C or more; the introduction process of the aluminum element is simple, the raw material cost is low, and the prepared aluminum-containing zirconia hollow microsphere has stable structure and good dispersibility.

Owner:SOUTHEAST UNIV

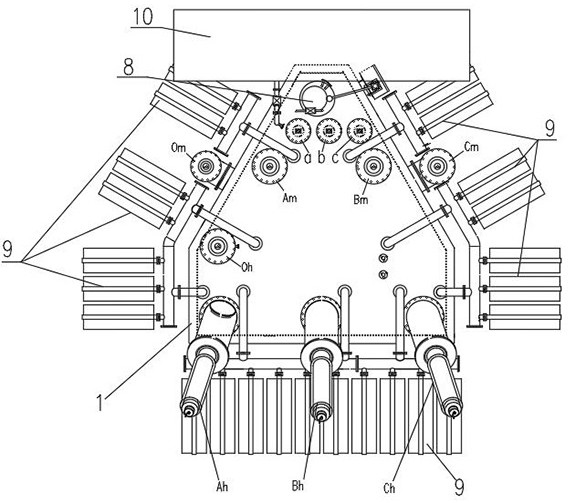

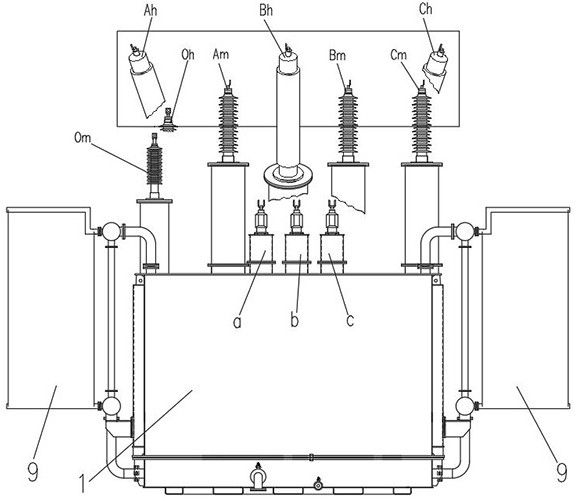

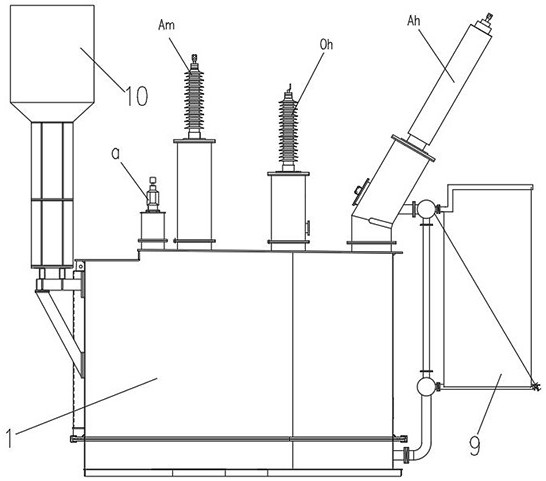

A 220kV Three-dimensional Wound Core Power Transformer and Core Manufacturing Method

ActiveCN113035525BSolve the problem of not being able to withstand high temperatureImprove cooling effectTransformers/inductances coolingTransformers/inductances coils/windings/connectionsStructural engineeringLoad loss

The invention discloses a 220kV three-dimensional wound core power transformer and a method for manufacturing an iron core. It includes an oil tank and an iron core assembly arranged in the oil tank. The iron core assembly includes three double-frame iron cores arranged in an equilateral triangle, and each two The vertical frames of the double-frame iron core are joined together to form a core column, and windings are arranged on the vertical outer periphery of the iron core column; the double-frame iron core includes an inner frame iron core and an outer frame iron core, and the inner frame iron core and the outer frame iron core A first oil passage is provided, and a second oil passage is provided between every two assembled inner frame cores, and every two assembled inner frame iron cores are connected with two assembled inner frame iron cores outside the inner frame iron cores. Vertical oil holes are arranged between the iron cores of the outer frame. The invention provides a 220kV three-dimensional wound core power transformer and a manufacturing method for the iron core. The three-dimensional wound core power transformer has low no-load loss, small no-load current, low noise and strong short-circuit resistance.

Owner:CHANGZHOU TIANDAO TRANSFORMER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com