Synthesis method of water-soluble triene cross-linking agent and high-temperature resistant water-absorbing resin

A technology of triene crosslinking agent and synthesis method, which is applied in the direction of organic chemistry and the preparation of functional groups substituted with amino groups, can solve the problems of high temperature resistance, achieve good product performance, broaden the application range, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

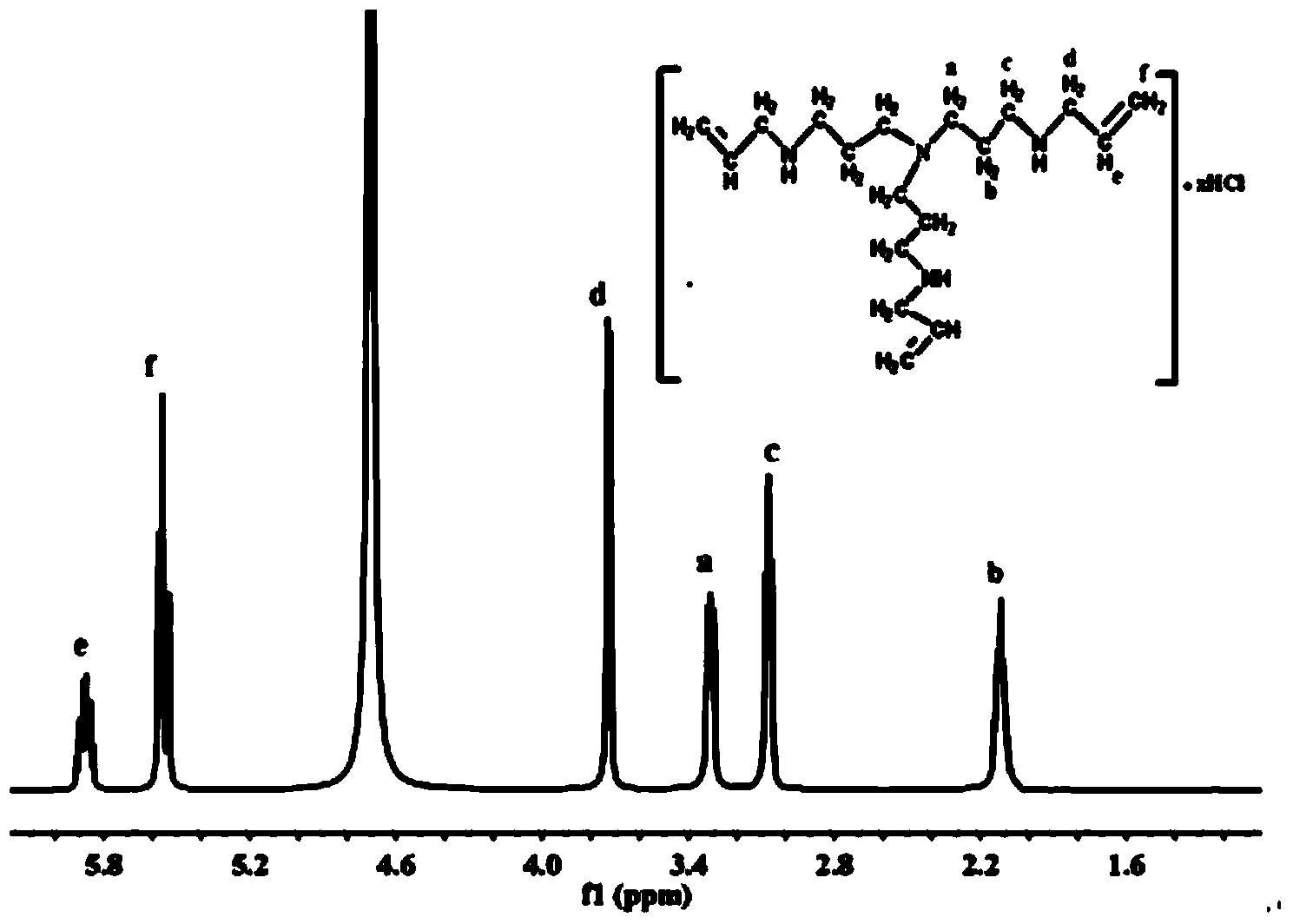

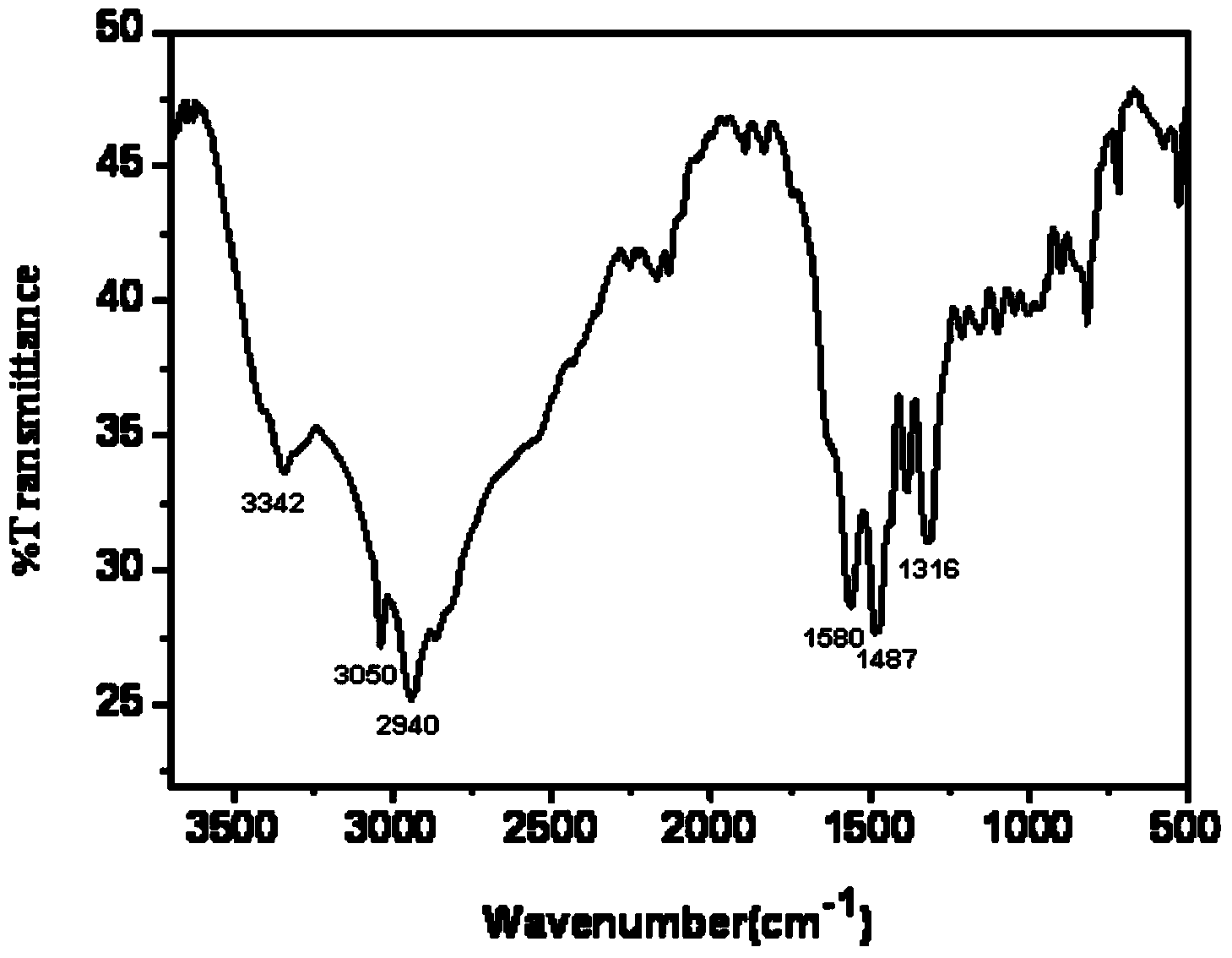

Embodiment 1

[0026] Add 18.8g (0.1mol) of triaminopropylamine, 40g of water, and 0.42g of cetyltrimethylammonium chloride into the reaction flask, stir and mix evenly, control the reaction temperature at 30-35°C, and drop in 4h Add 24.1 g (0.315 mol) of chloropropene, control the reaction temperature not to exceed 35°C, continue stirring until the system is transparent after adding chloropropene dropwise, and obtain an aqueous solution of a water-soluble triene crosslinking agent with an effective concentration of about 50.4%.

Embodiment 2

[0028] Add 28.2g (0.15mol) of triaminopropylamine, 60g of water, and 0.63g of dodecyldimethylbenzyl ammonium chloride into the reaction flask, stir and mix evenly, control the reaction temperature at 30-35°C, in 4h Add 36.1 g (0.472 mol) of allyl chloride dropwise, and control the reaction temperature not to exceed 35°C. After the addition of allyl chloride, continue stirring until the system is transparent, and then an aqueous solution of a water-soluble triene crosslinking agent is obtained, with an effective concentration of about 50.5%.

Embodiment 3

[0030] Add 50g of acrylic acid into the reaction kettle, and then neutralize it with 20% sodium hydroxide solution, the neutralization degree is 70%, add 10g of acrylamide and 0.2g of water-soluble triene crosslinking agent aqueous solution after cooling to room temperature (Example 1), add 0.075g of azobisisobutylimidazoline hydrochloride and 0.025g of ammonium persulfate after 30 minutes of nitrogen gas flow, stop feeding nitrogen gas after 10 minutes, and take out the product after 4 hours and place it in an 80°C Dry and pulverize in a vacuum oven to obtain a high-temperature-resistant water-absorbing resin. The water absorption rate was measured by the natural rate method, and the water absorption rate in distilled water at 300°C was 262g / g, and the water absorption rate in 0.9% NaCl was 75g / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com