Fabric shaping/dryer energy conservation and emission reduction control system and method for textile and dying industry

A technology of energy saving, emission reduction and control system, applied in the direction of processing textile material equipment configuration, etc., can solve the problems of heat waste, energy waste, temperature, humidity, smoke concentration and wrong exhaust, to avoid energy, solve high temperature resistance, Improve the effect of printing and dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

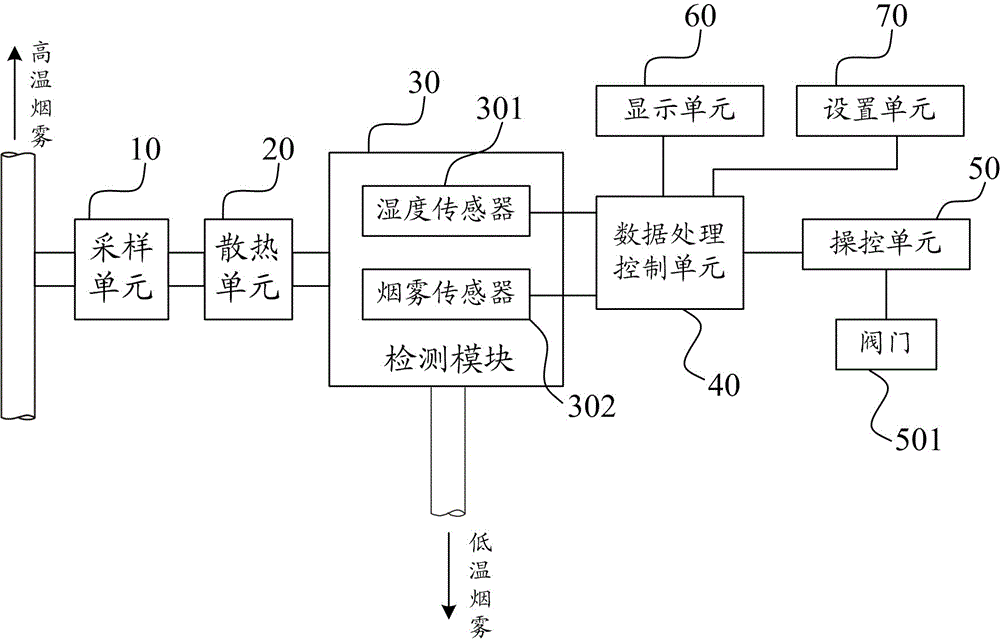

[0024] The energy-saving and emission-reduction control system for fabric setting / drying machine in the textile printing and dyeing industry according to the embodiment of the present invention includes a sampling unit, a heat dissipation unit, a detection module, a data processing control unit, a control unit, a display unit and a setting unit;

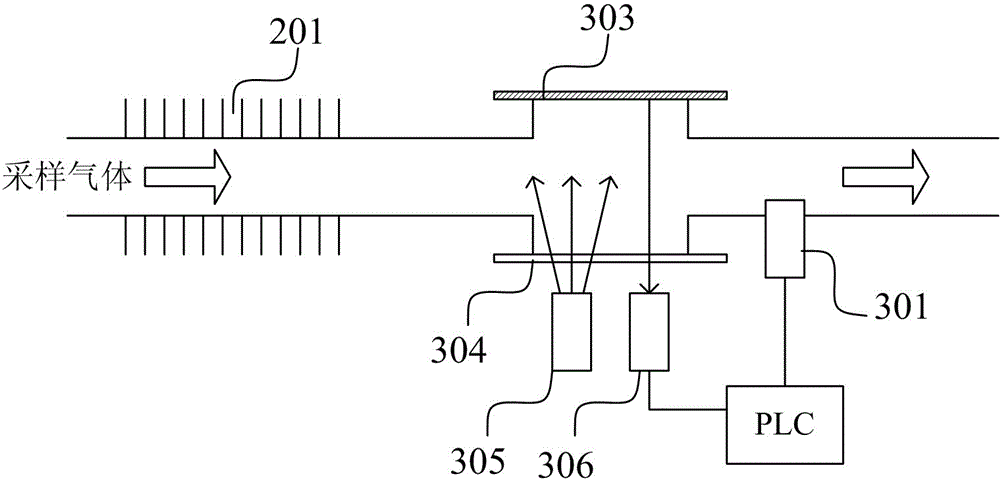

[0025] The sampling unit 10 obtains the sampled gas from the main air path of the sizing dryer, and inputs the sampled gas into the system. Since this system is applied to the sizing or drying machine for fabrics in the textile printing and dyeing industry, the gas produced is The temperature of high temperature gas ranges from 150°C to 250°C, which is not conducive to the normal operation of ordinary humidity sensors and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com