Aluminum-containing zirconia hollow microspheres and preparation method thereof

A technology of hollow microspheres and zirconia, which is applied in the direction of zirconia, can solve the problems of limited use and poor high temperature resistance of zirconia hollow microspheres, and achieve the effects of low temperature resistance, good dispersion and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

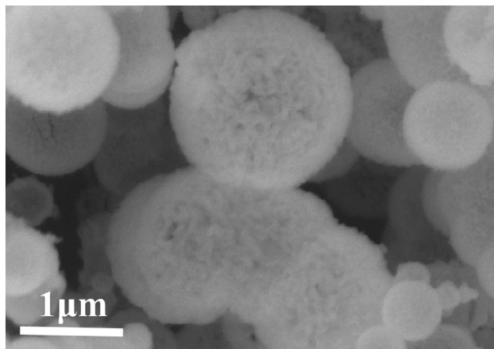

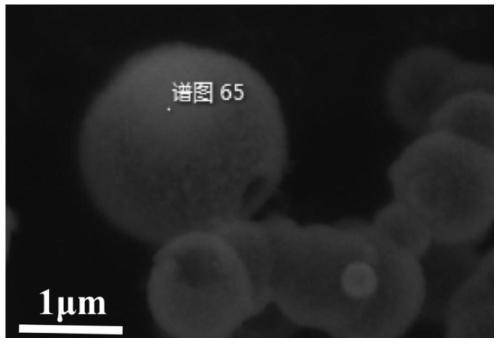

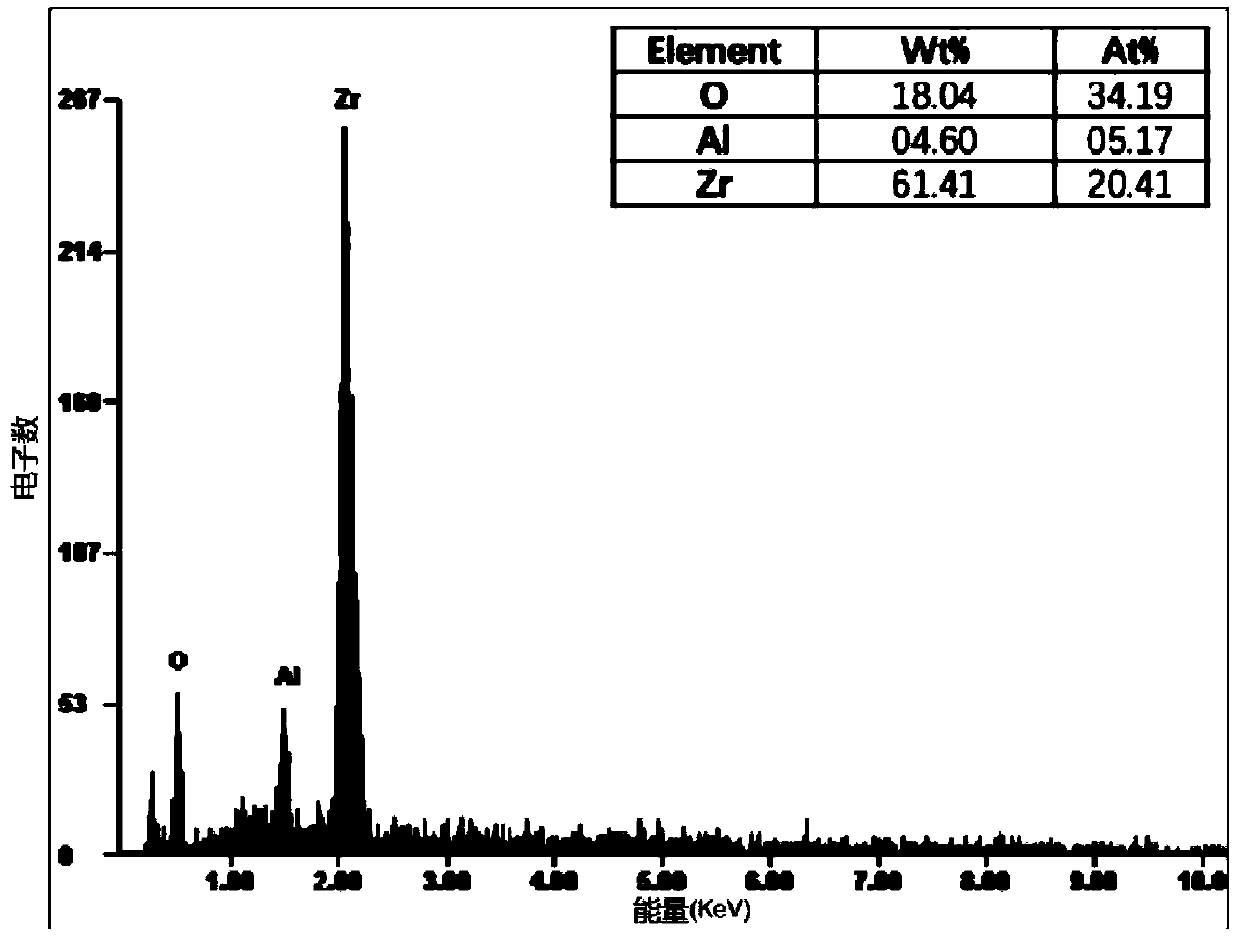

[0023] The preparation method of aluminum-containing zirconia hollow microspheres is as follows:

[0024] Add 0.008mol of aluminum nitrate, 0.016mol of zirconium oxychloride, and 0.032mol of urea into 200ml of absolute ethanol, and slowly add 50ml of concentrated hydrochloric acid (concentration of hydrogen ions in concentrated hydrochloric acid is 12mol / L) during the stirring process. Stir magnetically in a water bath until a clear solution is obtained. The prepared clear solution was poured into a stainless steel reactor lined with polytetrafluoroethylene, sealed and heated in an oven at 160°C for 12h. After the reaction was completed and naturally cooled, the precipitate produced by the reaction was filtered out, washed three times with absolute ethanol, and placed in an oven at 60° C. for 24 hours until completely dried. The powder obtained after drying was calcined at 1000° C. for 2 hours to obtain aluminum-containing zirconia hollow microspheres, and a part of the alumi...

Embodiment 2

[0026] The preparation method of aluminum-containing zirconia hollow microspheres is as follows:

[0027] Add 0.004mol of aluminum nitrate, 0.016mol of zirconium oxychloride, and 0.032mol of urea into 200ml of absolute ethanol, and slowly add 50ml of concentrated hydrochloric acid (concentration of hydrogen ions in concentrated hydrochloric acid is 12mol / L) during the stirring process. Stir magnetically in a water bath until a clear solution is obtained. The prepared clear solution was poured into a stainless steel reactor lined with polytetrafluoroethylene, sealed and heated in an oven at 160°C for 12h. After the reaction is completed and cooled naturally, the precipitate produced by the reaction is filtered out, washed three times with absolute ethanol, and placed in an oven at 60°C for 24 hours to completely dry; the powder obtained after drying is calcined at 1000°C for 2 hours to obtain an aluminum-containing Zirconia hollow microspheres, and a part of aluminum-containin...

Embodiment 3

[0029] The preparation method of aluminum-containing zirconia hollow microspheres is as follows:

[0030] Add 0.002mol of aluminum nitrate, 0.016mol of zirconium oxychloride, and 0.032mol of urea into 200ml of absolute ethanol, and slowly add 50ml of concentrated hydrochloric acid (the concentration of hydrogen ions in the concentrated hydrochloric acid is 12mol / L) during the stirring process. Stir magnetically in a water bath until a clear solution is obtained. The prepared clear solution was poured into a stainless steel reactor lined with polytetrafluoroethylene, sealed and heated in an oven at 160°C for 12h. After the reaction is completed and cooled naturally, the precipitate produced by the reaction is filtered out, washed three times with absolute ethanol, and placed in an oven at 60°C for 24 hours to completely dry; the powder obtained after drying is calcined at 1000°C for 2 hours to obtain an aluminum-containing Zirconia hollow microspheres, and a part of aluminum-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com