Hydrophobic moisture-resistant coating as well as preparation method and application thereof

A moisture-blocking and coating technology, applied in the coating and other directions, can solve the problems of poor stability and weak adhesion on the surface of the substrate, and achieve the effect of enhancing the bonding strength, excellent bonding, and increasing the diffusion path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

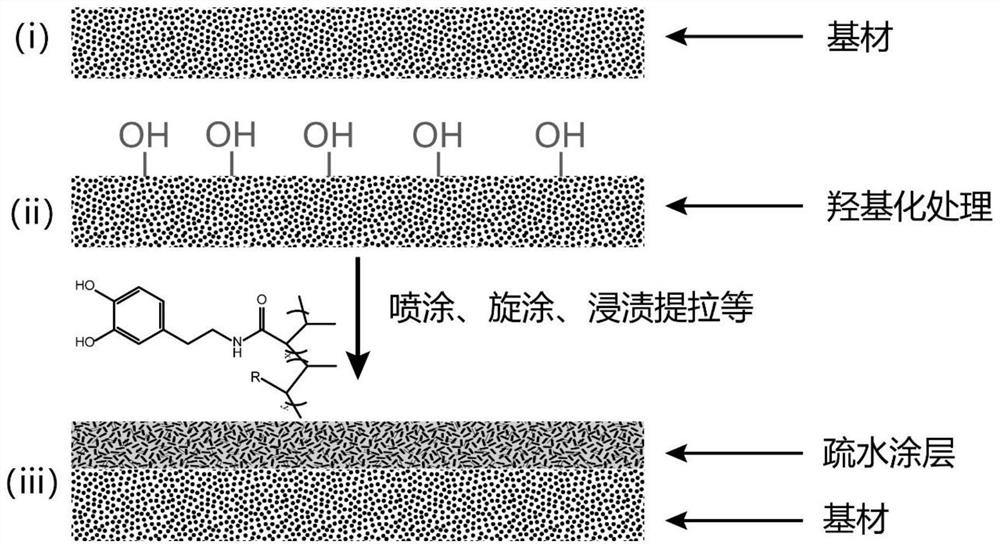

[0024] The invention provides a preparation method of a hydrophobic and moisture-blocking coating, comprising the following steps;

[0025] Reacting dopamine hydrochloride with methacrylic substances to obtain 3-methacrylic acid-based dopamine;

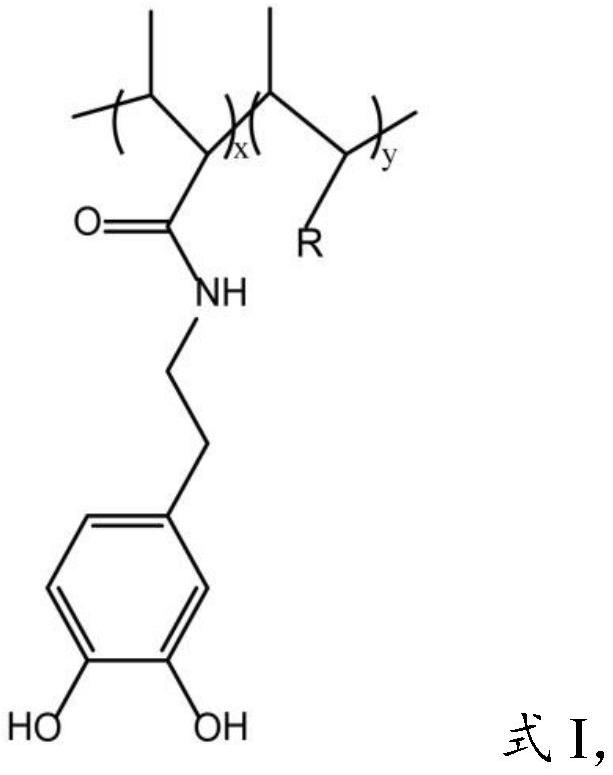

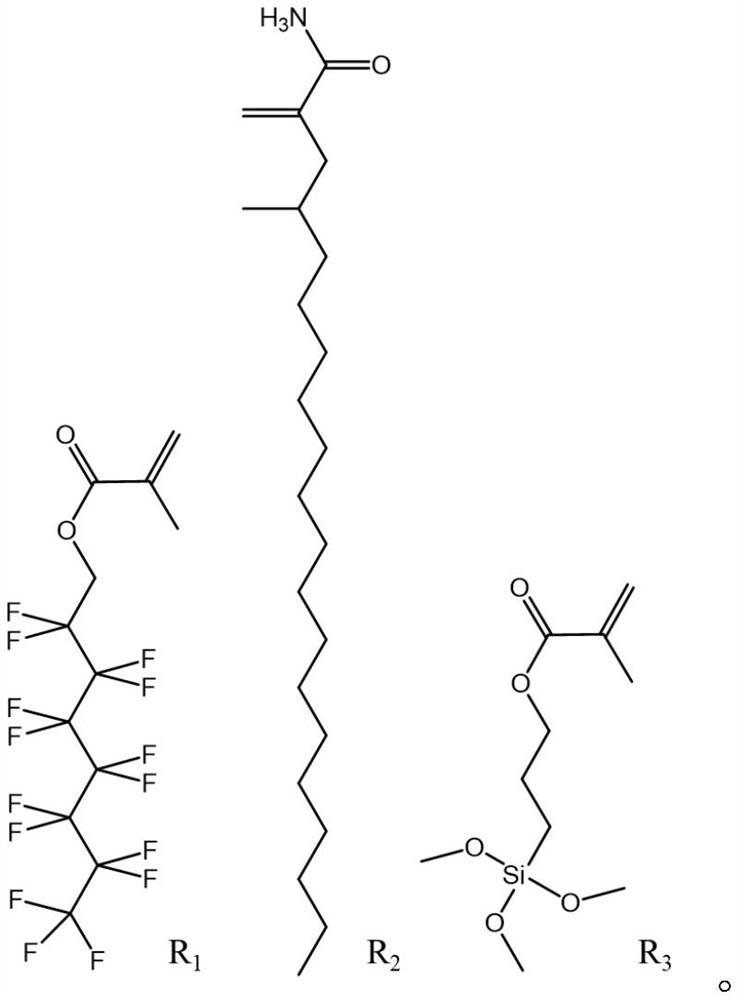

[0026] Mixing the 3-methacrylic acid-based dopamine, polymerized monomers and azobisisobutyronitrile to carry out radical polymerization to obtain a dopamine copolymer, wherein the polymerized monomers are acrylates, acrylamides or silicones side chain group organics;

[0027] mixing the dopamine copolymer, organic solvent and filler to obtain a coating;

[0028] The substrate is subjected to oxygen plasma surface hydroxylation to obtain a pretreated substrate;

[0029] The coating is applied on the surface of the pretreated substrate to obtain the hydrophobic moisture barrier coating.

[0030] In the present invention, unless otherwise specified, the raw materials used are all commercially available products in the field.

[0031...

Embodiment 1

[0066] Weigh 5 g of dopamine hydrochloride, 250 mL of deionized water, and adjust the pH of the solution to 10; weigh 5 g of methacrylic acid chloride to mix and react, then acidify the reaction product and extract to obtain 3-methacryloyl dopamine.

[0067] Weigh 2.5g acrylic acid, 125g methacrylic acid-1H,1H-perfluorooctyl ester, 125g 3-methacryloyl dopamine, configure 8% azobisisobutyronitrile (AIBN) initiator, mix The solution was subjected to radical polymerization under nitrogen atmosphere to obtain dopamine copolymer-R 1 , dopamine copolymer-R 1 The structure of is as follows:

[0068]

[0069] x: 5 to 15, y: 10 to 100.

[0070] Synthetic dopamine copolymer-R 1 Dissolved in the mixed solution of butyl acetate and xylene (volume ratio 2:1), the mass fraction is 2%.

[0071] Take the reduced graphene into the paint, and the mass fraction of the reduced graphene is 0.2%. Magnetic stirring to make it fully mixed, that is, to obtain the hydrophobic dopamine copolymer...

Embodiment 2

[0086] The same as Example 1, the difference is only that the single reduced graphene filler in Example 1 is replaced with a mixed filler of reduced graphene and carbon nanotubes, and the total mass is equal to the quality of the reduced graphene in Example 1, and the reduced graphene The mass ratio of carbon nanotubes is 1:1.

[0087] Reference standard: GB / T 20313-2005; with reference to the method in Example 1, the moisture barrier coating samples were prepared, and the contact angle and moisture barrier effect were characterized. The results are shown in Tables 2.1 to 2.3. It can be seen from Table 2.1 that the dopamine copolymer mixed coating has good hydrophobicity.

[0088] Table 2.1 Contact angles of the hydrophobic moisture barrier coating samples and blank substrates prepared in Example 2

[0089]

[0090] Prepare 15 samples with a hydrophobic coating thickness of 20 μm according to the formula in Example 2, and use the industry standard moisture-proof cup for pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com