A 220kV Three-dimensional Wound Core Power Transformer and Core Manufacturing Method

A technology of power transformers and three-dimensional wound cores, which is applied in the field of power transformers, can solve the problems that the heat dissipation structure of laminated cores cannot be applied to wound cores, the oil channel buckle cannot withstand the high temperature of annealing, and the toughness of high temperature resistant materials is insufficient, etc., to achieve novel structure, Good heat dissipation effect and optimized heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

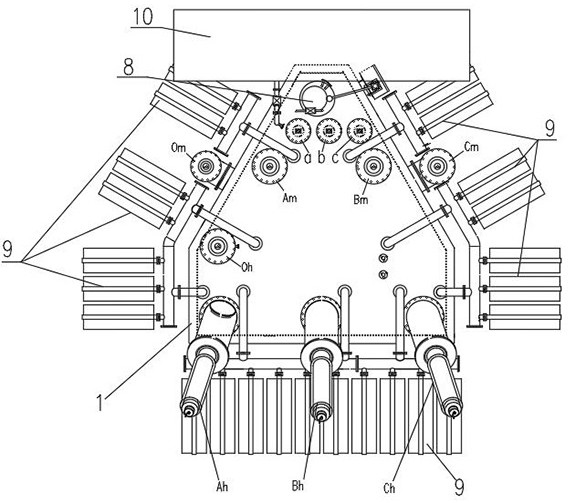

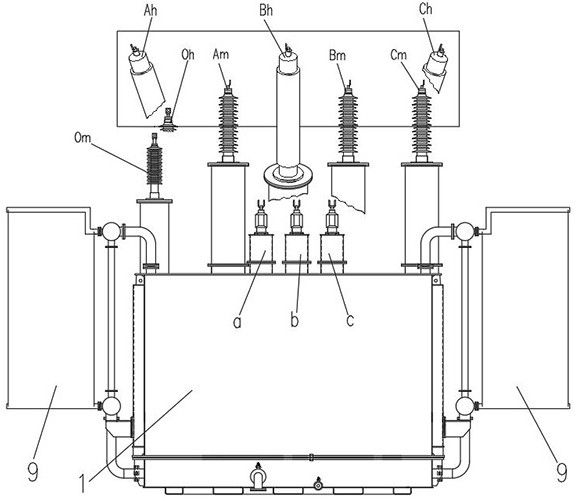

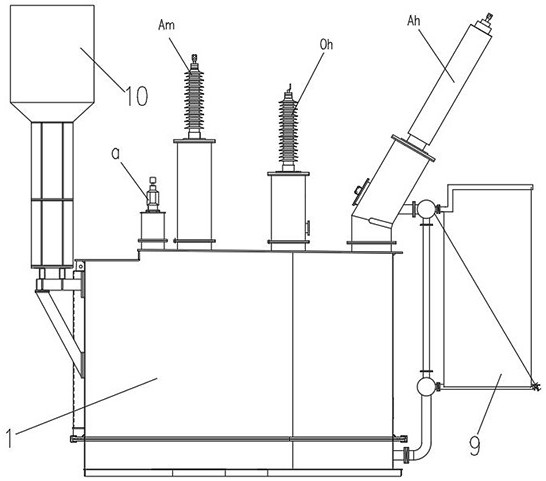

[0034] Such as Figure 1~6 As shown, a 220kV three-dimensional wound core power transformer includes an oil tank 1 and an iron core assembly arranged in the oil tank 1. The oil tank 1 is filled with transformer oil. The iron core assembly includes three double-frame iron cores arranged in an equilateral triangle, each The vertical frames of the two double-frame iron cores are joined together to form an iron core column, and windings are arranged on the vertical outer periphery of the iron core column.

[0035] This embodiment provides a preferred structure of a double-frame iron core, such as Figure 5 As shown, the double frame iron core includes an inner frame iron core 21 and an outer frame iron core 22 , the included angle between the two inner frame iron cores 21 is 60°, and the included angle between the two outer frame iron cores 22 is 60°.

[0036] Such as Figure 5 As shown, a first oil passage 31 is provided between the inner frame core 21 and the outer frame core ...

Embodiment 2

[0048] A method for manufacturing an iron core of a 220kV three-dimensional wound core power transformer, comprising:

[0049] S1, winding three inner frame iron cores 21 and three outer frame iron cores 22 respectively;

[0050] S2. Perform high-temperature annealing treatment on the wound inner frame iron core 21 and outer frame iron core 22;

[0051] S3. The inner frame iron core 21 and the outer frame iron core 22 after the high temperature annealing treatment are assembled. When merging, the first oil passage 31 is assembled between the inner frame iron core 21 and the outer frame iron core 22, and every two outer frame iron cores 22 The second oil passage 32 is assembled therebetween.

[0052] The iron core assembly of this embodiment is assembled after the inner frame iron core 21 and the outer frame iron core 22 are annealed at high temperature, and put into the oil passage during the assembly, which solves the problem that the heat dissipation oil passage cannot with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com