A high-temperature resistant wax anticorrosion material

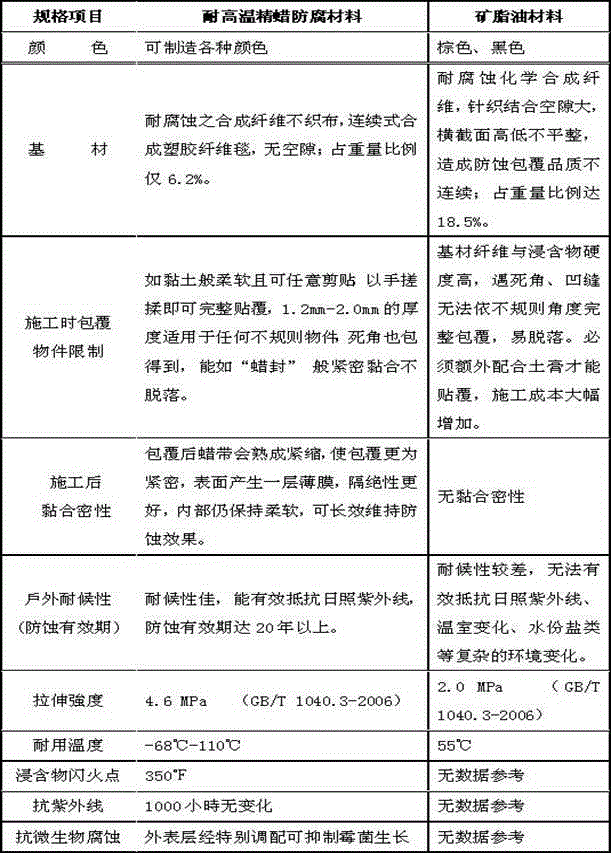

An anti-corrosion material and high-temperature-resistant technology, which is applied in the field of metal anti-corrosion, can solve the problems of flexible anti-corrosion materials that cannot withstand high temperature, components are easily lost, and volatilized, and achieve the effects of inhibiting the growth of mold, good sealing effect, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 3% polyethylene wax and 20% polytetrafluoroethylene modified polyethylene wax into the mixing tank and heat to 130 °C until all the materials are melted and stir for 10 minutes, then add 4.5% 2,6-to-two Tert-butyl p-cresol, 25% white oil, 3% sodium petroleum sulfonate, 10% fumed silica, 0.1% polysiloxane, stirred and dispersed for 10 minutes, then put the prepared raw materials into the soaking tank, and put The polyester fiber non-woven fabric is soaked in the soaking tank for 3 minutes and then transported to the cooling drum. After cooling to normal temperature, it is immersed in the slitting and rewinding machine, slitting and winding according to the required length and width, and then packed into the warehouse.

Embodiment 2

[0022] Add 70% polyethylene wax and 5% polytetrafluoroethylene modified polyethylene wax into the mixing tank and heat to 180 °C until all the materials are melted and stir for 1 minute, then add 0.5% 2,6-to-two Tert-butyl p-cresol, 5% white oil, 2% sodium petroleum sulfonate, 1.5% fumed silica, 0.5% polysiloxane, stirred and dispersed for 50 minutes, then put the prepared raw materials into the immersion tank, and put The polyester fiber non-woven fabric is soaked in the soaking tank for 20 minutes and then transported to the cooling drum. After cooling to normal temperature, it is immersed in the slitting and rewinding machine, slitting and winding according to the required length and width, and then packed into the warehouse.

Embodiment 3

[0024] Add 70% polyethylene wax and 10% polytetrafluoroethylene modified polyethylene wax into the mixing tank and heat to 150°C until all the materials are melted and stir for 5 minutes, then add 2% 2,6-to-two Tert-butyl p-cresol, 15% white oil, 2% sodium petroleum sulfonate, 6% fumed silica, 0.3% polysiloxane, stirred and dispersed for 30 minutes, then put the prepared raw materials into the soaking tank, and put The polyester fiber non-woven fabric is soaked in the soaking tank for 10 minutes and then transported to the cooling drum. After cooling to normal temperature, it is immersed in the slitting and rewinding machine. It is cut and rewound according to the required length and width, and then packed into the warehouse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com