Multifunctional organic silicon thermal interface material

A thermal interface material, silicone technology, applied in the field of heat dissipation materials, can solve the problems of low heat dissipation efficiency of ceramic radiators, failure to meet insulation safety requirements, failure to meet heat dissipation requirements, etc., to achieve lower temperature, easy implementation, and high flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

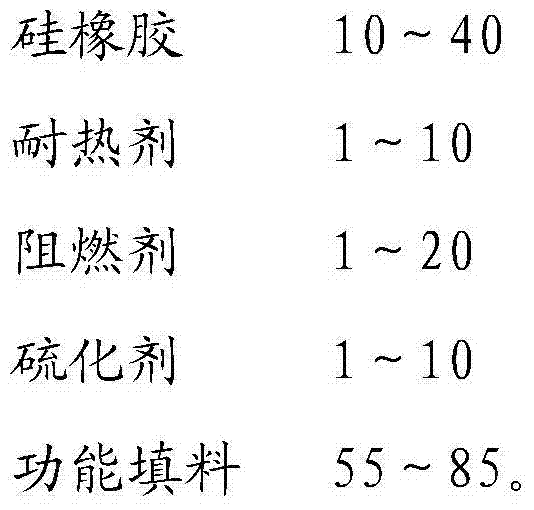

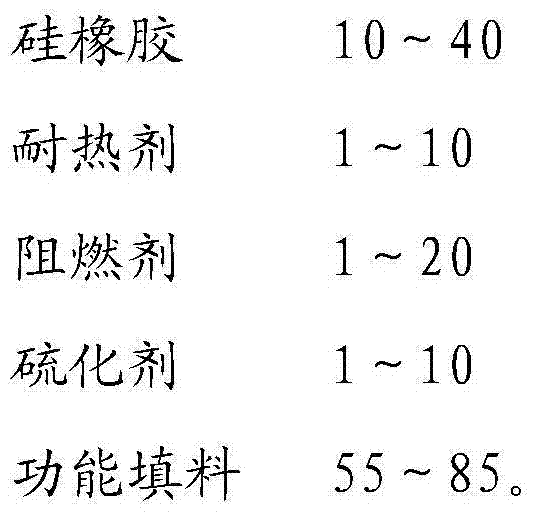

Method used

Image

Examples

Embodiment 1

[0018] Take 10kg of boron nitride powder, 30kg of silicon nitride powder, 50kg of aluminum oxide powder, 5kg of iron oxide powder, 3kg of aluminum hydroxide powder, and 20kg of methyl vinyl silicone rubber, and stir them in a stirrer Mix for 30 minutes, then place the mixture in a two-roller mill, add 2Kg of double-two-fourth vulcanizing agent in the two-roller mill and open for 20 minutes, and the formed composite material is calendered on a glass fiber with a thickness of 0.1mm After the thickness reaches 0.5mm, it is dried at a temperature of 120°C and vulcanized to form the multifunctional organic silicon thermal interface material of the present invention.

[0019] According to the measurement, the thermal conductivity of the multifunctional silicone thermal interface material is 1.23W / m·K, the breakdown voltage is 7KV, and the flame retardancy is UL 94V-0.

[0020] After baking at 280°C for 1000 hours, the thermal conductivity of the silicone thermal interface material i...

Embodiment 2

[0022] Take 20kg of boron nitride powder, 30kg of silicon nitride powder, 70kg of aluminum oxide powder, 2kg of iron oxide powder, 2kg of cerium oxide powder, 2kg of aluminum hydroxide powder, and 20kg of methyl vinyl silicone rubber , stirred and mixed in the agitator for 30 minutes, then put the mixture in a two-roll mill, add 2kg of bis-two-four vulcanizing agent in the two-roll mill and knead for 20 minutes, and the formed composite material is calendered to a thickness of After the thickness reaches 0.4mm, it is dried and vulcanized at a temperature of 120° C. to form the multifunctional organic silicon thermal interface material of the present invention.

[0023] After measurement, the thermal conductivity of the multifunctional silicone thermal interface material is 1.75W / m·K, the breakdown voltage is 8.5KV, and the flame retardancy is UL 94V-0.

[0024] After baking at 280°C for 1000 hours, the thermal conductivity of the multifunctional silicone thermal interface mate...

Embodiment 3

[0026] Take 40kg of boron nitride powder, 10kg of silicon nitride powder, 30kg of aluminum oxide powder, 5kg of iron oxide powder, 5kg of aluminum hydroxide powder, and 20kg of methyl vinyl silicone rubber, and stir in the mixer Mix for 30 minutes, then place the mixture in a two-roller mill, add 2kg of double-two-fourth vulcanizing agent in the two-roller mill and open for 20 minutes, and the formed composite material is rolled on the polyimide of 0.05mm On the film, after the thickness reaches 0.3mm, it is dried at a temperature of 120° C., and vulcanized. The multifunctional organic silicon thermal interface material of the present invention.

[0027] After measurement, the thermal conductivity of the multifunctional silicone thermal interface material is 0.85W / m·K, the breakdown voltage is 8KV, and the flame retardancy is UL 94V-0.

[0028] After baking at 280°C for 1000 hours, the thermal conductivity of the multifunctional silicone thermal interface material is 0.82W / m·K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com