Electrical connector and production method thereof

A technology for electrical connectors and manufacturing methods, which is applied in the direction of connection, line/collector components, circuits, etc., can solve the problems of conductive rubber not being resistant to high temperatures, and achieve the effects of not being resistant to high temperatures, simple process, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

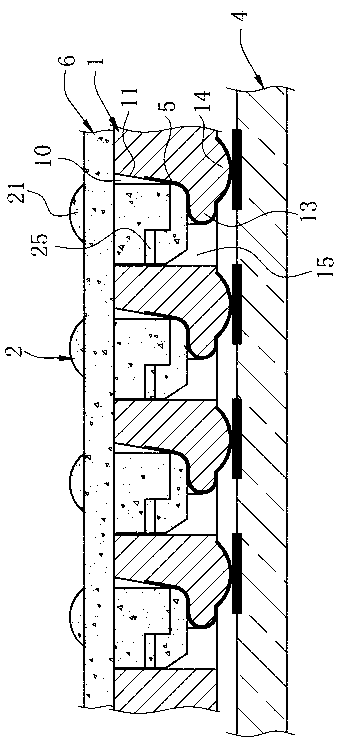

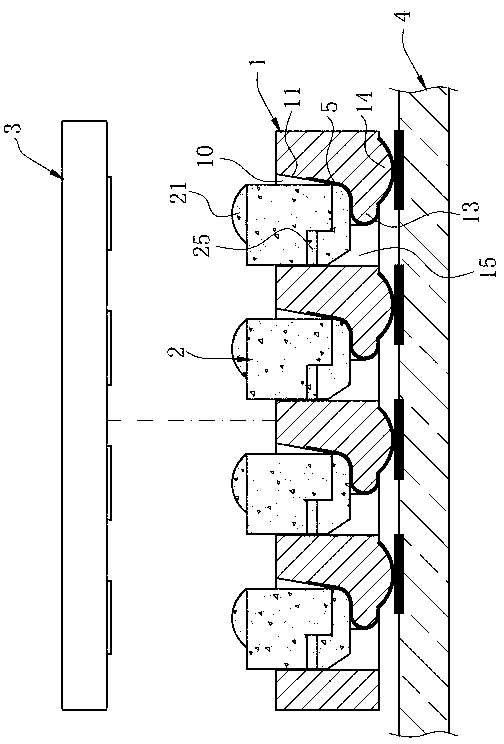

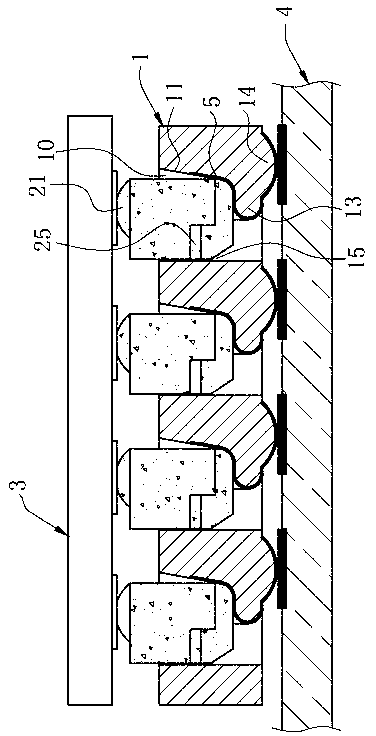

[0041] See figure 1 and figure 2The insulation body 1 is an integrated formation of forming, and there are multiple containers 10, which is arranged by the 10 matrix of the container 10.The container 10 is surrounded by the two first side wall 11 and the second side of the second side of the second side.The second and second side wall 12 is also relatively set.In this embodiment, there is a conductive layer 5 on one of the first side wall 11, which is usually electroplated or copper and other conductive materials.The first side wall 11, which is plated with the guidance layer 5, extends to the one -to -bottom 13 to the one -to -bottom of the container 10, which gradually becomes smaller from top to bottom, and it has stopped from top to bottom.The role of blocking limit.The conductive layer 5 also covers the bottom surface of the Municipal Department 13, and extends to the bottom surface of the insulation body 1.The formation of one welding is 14.There is a two -card holding depar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com