Ice-cold polyethylene fiber wash-and-wear shirt fabric and processing method thereof

An ethylene fiber and ice-cold technology, which is applied in the field of ice-cold ethylene fiber non-iron shirting fabrics and its processing, can solve the problems of no coolness, the coldness of the ice-cold silk is not as good as that of polyethylene, and the comfort is poor. Excellent contact cool feeling, solving the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

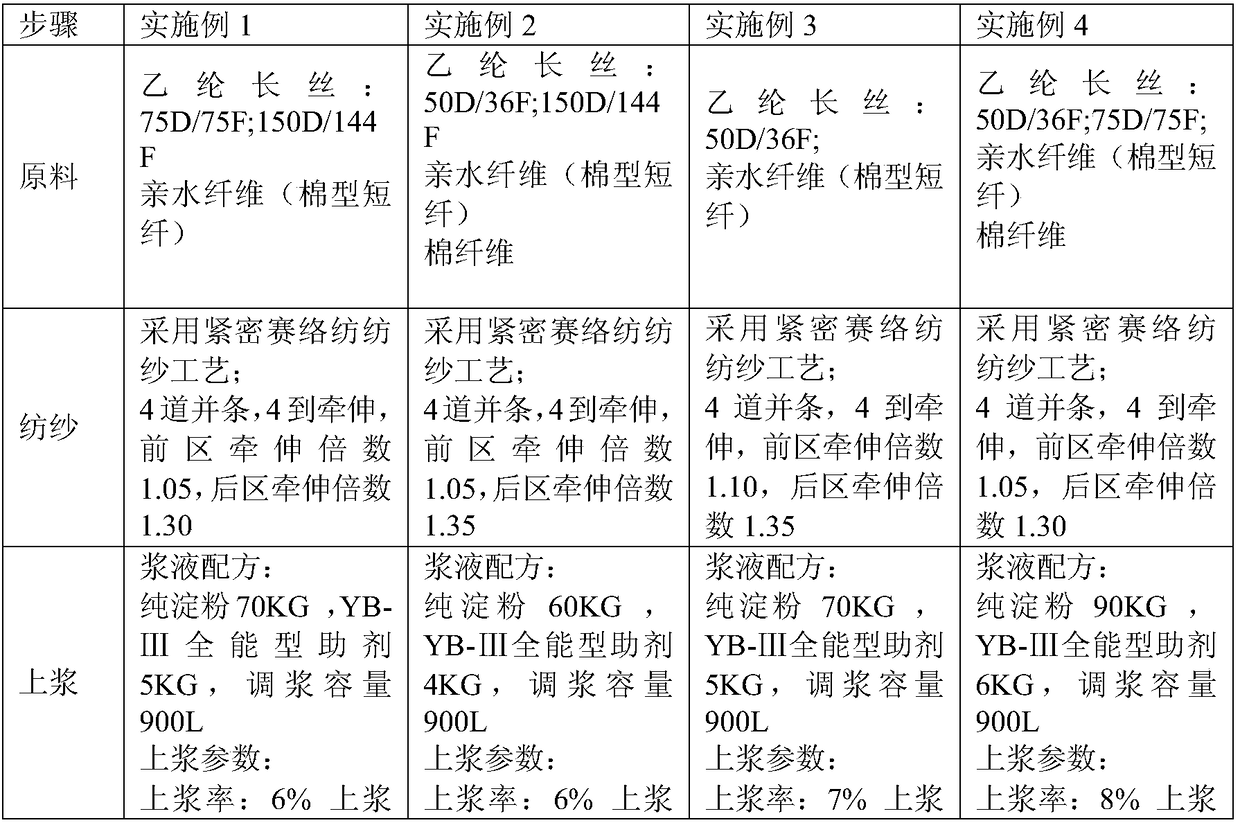

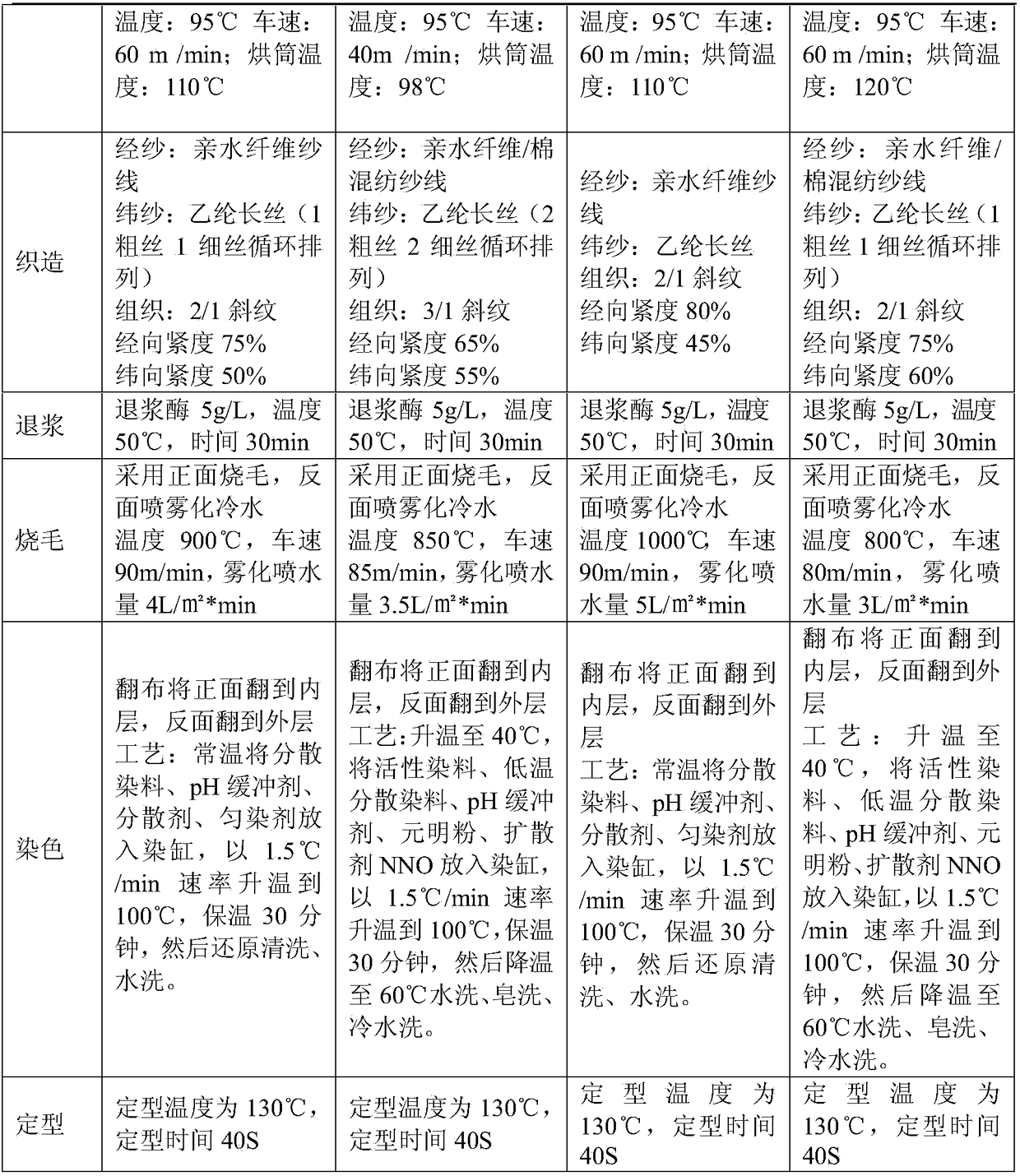

Embodiment 1-4

[0026]

[0027]

[0028] The effect statistics of embodiment:

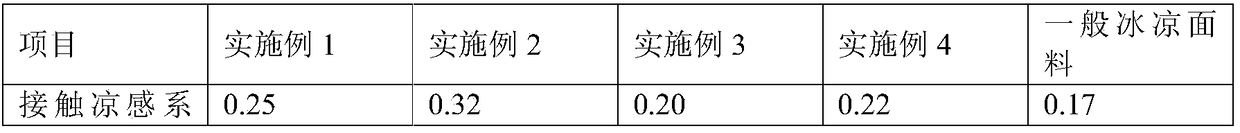

[0029] The cold silk fabrics (abbreviation: general cool fabrics) woven from the polyester fibers of the mineral powders in Examples 1 to 4 were compared with the contact cooling coefficient, water absorption rate, drip diffusion time, evaporation rate and other properties, and the specifications of the general cool fabrics It is a conventional specification in the market, and the warp and weft directions are cold silk containing mineral powder. The results are shown in Table 1.

[0030] Table 1:

[0031]

[0032]

[0033] Note: The contact cooling coefficient ≥ 0.15 means that it has the performance of instant cooling;

[0034] As shown in Table 1:

[0035] 1. Compared with general cool fabrics, the cool-touch polyethylene non-ironing shirt fabric of the present invention has better cool-touch performance, and the cool-touch performance of Example 2 is the best, mainly because of its organizational ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com