High-temperature-resistant metal lithium negative electrode as well as preparation method and application thereof

A lithium metal, high temperature resistant technology, applied in negative electrodes, lithium batteries, battery electrodes, etc., can solve problems such as battery structure damage, battery safety accidents, metal lithium negative electrode melting, etc., and achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Preparation of high temperature resistant metal lithium anode

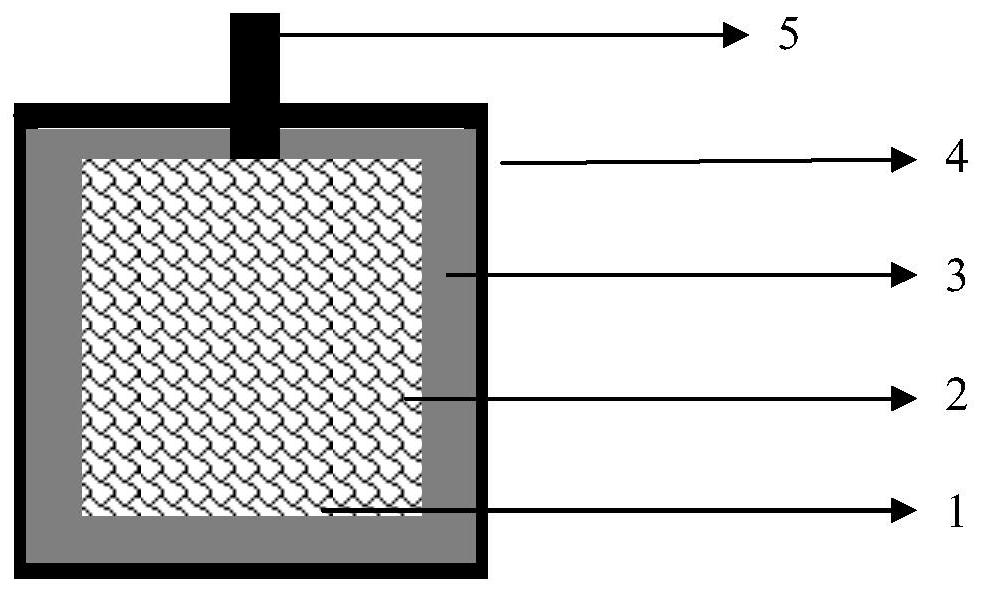

[0055] The polyimide was melted, and a supporting framework 1 with a thickness of 10 microns was prepared by electrospinning. The prepared supporting frame 1 is placed between two layers of metal lithium foils with a thickness of 20 microns, and at the same time, the tab 5 is placed in a suitable position between the lithium foil and the supporting frame and rolled together to obtain a metal lithium core. Adjust the electrospinning process to prepare a porous polyimide protective layer 3 on the surface of the lithium metal core. After the porous protective layer 3 is dried, it is immersed in the slurry of the sulfide solid electrolyte (except the tabs), and dried to obtain a high-temperature-resistant lithium metal negative electrode.

Embodiment 2

[0057] Preparation of high temperature resistant metal lithium anode

[0058] Polytetrafluoroethylene was melted, and a support framework 1 with a thickness of 5 microns was prepared by electrospinning. The prepared support frame 1 is placed between two layers of metal lithium foil with a thickness of 10 microns, and at the same time, the tab 5 is placed at a suitable position outside the lithium foil and rolled together to obtain a metal lithium core with tabs . Adjusting the vapor deposition process, depositing a layer of porous copper plating with a thickness of 10 nm on the surface of the lithium metal core to obtain the porous protective layer 3 . Submerge the above-mentioned pole piece in the slurry of the sulfide solid electrolyte (except the tab), and dry to obtain a high-temperature-resistant lithium metal negative electrode.

Embodiment 3

[0060] Preparation of high temperature resistant metal lithium anode

[0061] Polytetrafluoroethylene was melted, and a support framework 1 with a thickness of 15 microns was prepared by electrospinning. The prepared support frame 1 is placed between two layers of metal lithium foils with a thickness of 20 microns, and at the same time, the tab 5 is placed at a suitable position outside the lithium foil and rolled together to obtain a metal lithium core with tabs . Adjust the electrospinning process to prepare a porous protective layer of tetrafluoroethylene on the surface of the lithium metal core 3 . After the porous protective layer 3 is dried, the slurry of the sulfide solid electrolyte is coated on the porous protective layer (except the tabs) and dried. The side of the pole piece is sealed with molten polytetrafluoroethylene, and dried to obtain a high-temperature-resistant metal lithium negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com