Electron beam curing type hot-melt pressure-sensitive adhesive and application thereof

A technology of electron beam curing and pressure-sensitive adhesives, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problem of softness and adhesion, mismatch of peel strength, consumption of large heat source energy, organic solvents Volatility and other problems, to avoid loss or change of viscosity and gel formation, to ensure the initial adhesion performance, improve the effect of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

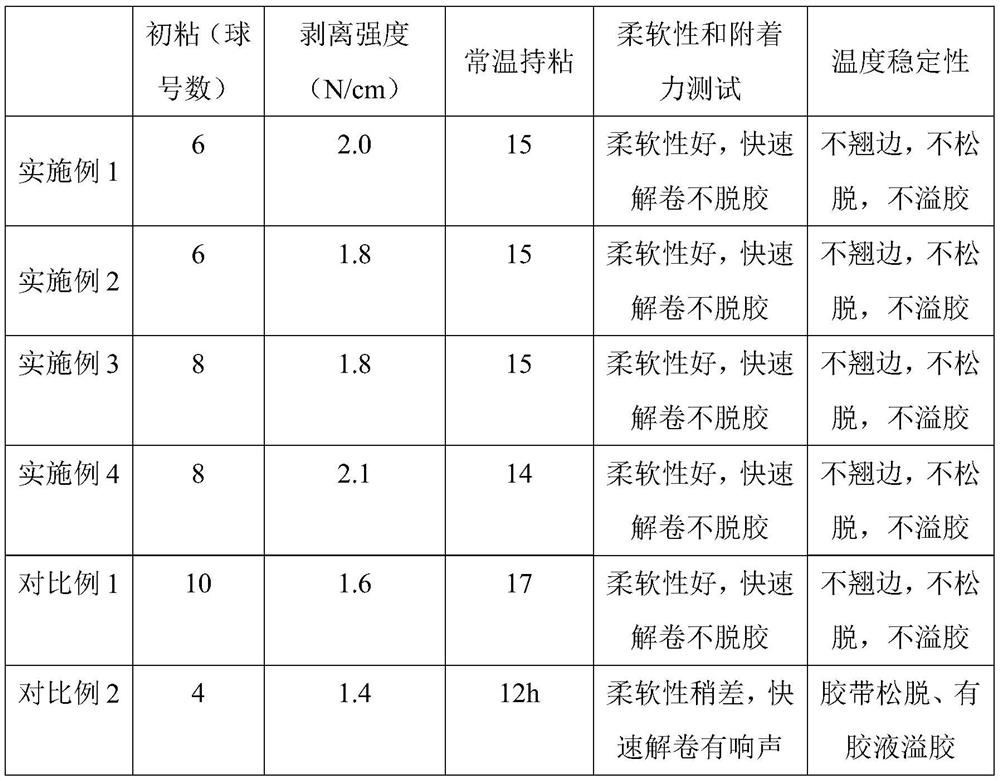

Examples

Embodiment 1

[0062] This example provides an adhesive. The raw materials for the preparation of the adhesive, in percentage by weight, include: acetone 40wt%, 2-ethylhexyl acrylate, 45wt%, acrylic acid, 11wt%, azobisisobutylene Nitrile 3wt%, antioxidant 10101wt%.

[0063] This example also provides the above-mentioned preparation method of the adhesive, including:

[0064] Add acetone to the reaction kettle, add 2-ethylhexyl acrylate, acrylic acid, azobisisobutyronitrile, antioxidant 1010, and add dropwise to the reaction kettle after mixing, fill with nitrogen for protection, and complete the dropwise addition within 5 hours , after completing the titration, continue to heat for 3 hours, and vacuumize the reaction kettle until the solvent is completely separated to obtain a light yellow transparent liquid adhesive.

Embodiment 2

[0066] This example provides an adhesive. The raw materials for the preparation of the adhesive, in terms of percentage by weight, include: butanone 45wt%, 2-ethylhexyl acrylate 41wt%, acrylic acid 10wt%, azobisisoheptanenitrile 3.2wt%, antioxidant 10760.8wt%.

[0067] This example also provides the above-mentioned preparation method of the adhesive, including:

[0068] Add butanone to the reaction kettle, add 2-ethylhexyl acrylate, acrylic acid, azobisisoheptanenitrile, antioxidant 1076, and add dropwise to the reaction kettle after mixing, fill with nitrogen for protection, and add dropwise within 5 hours After completion, after completing the titration, continue heating and heat preservation for 3 hours; vacuumize the reaction kettle until the solvent is completely separated to obtain a light yellow transparent liquid adhesive.

Embodiment 3

[0070] This example provides an adhesive. The raw materials for the preparation of the adhesive, in terms of weight percentages, include: methyl ethyl ketone 35wt%, ethyl acrylate 29wt%, isooctyl acrylate 12wt%, methyl acrylate 11wt%, acrylic acid 10wt%, azobisisobutyronitrile 2.7wt%, antioxidant 1076 0.3wt%.

[0071] This example also provides the above-mentioned preparation method of the adhesive, including:

[0072] Add butanone to the reaction kettle, mix ethyl acrylate, isooctyl acrylate, methyl acrylate, acrylic acid, azobisisobutyronitrile, and antioxidant 1076, add dropwise to the reaction kettle after mixing, fill with nitrogen for protection, and place in the The dropwise addition was completed within 5 hours, and after the titration was completed, the heating was continued for 3 hours, and the reaction kettle was evacuated until the solvent was completely separated to obtain a light yellow transparent liquid adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com