Microstructure control method for high toughness bearings and steel for nano-bainite bearings

A nano-bainite, bearing steel technology, applied in the field of bearing manufacturing, can solve the problems of increased manufacturing cost, reduced bearing manufacturing efficiency, long carburizing cycle, etc., so as to overcome the long carburizing cycle, reduce bearing manufacturing cost, improve The effect of bearing manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

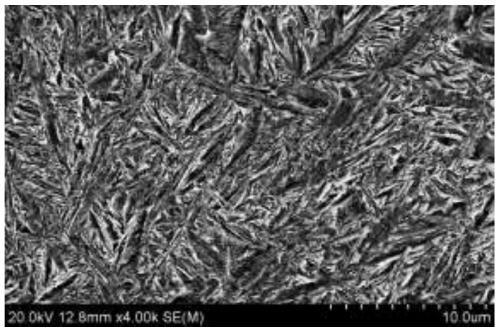

[0030] This embodiment provides a high-toughness nano-bainite steel for bearings. The core of the bearing steel is nano-bainite structure, and the surface layer is a mixed structure including high-carbon martensite structure.

[0031] Specifically, the core of the bearing steel is a complete nano-bainite structure. The size of the nanobainite structure is 30 nm to 80 nm. In this embodiment, the size of the nano-bainite structure may specifically be 50nm-70nm, so that the toughness of the steel core for bearings is further improved.

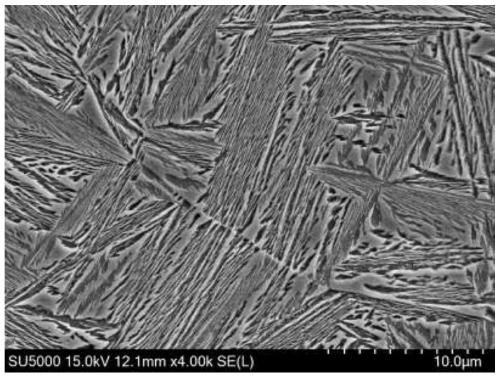

[0032] The surface layer of steel for bearings is a mixed structure including a high-carbon martensitic structure. Specifically, the surface layer of the bearing steel is a mixed structure composed of high carbon martensite and retained austenite. Wherein, in the mixed structure, the volume fraction of the high-carbon martensite structure is greater than 80%, and in this embodiment, the volume fraction of the high-carbon martensite structure can...

Embodiment 2

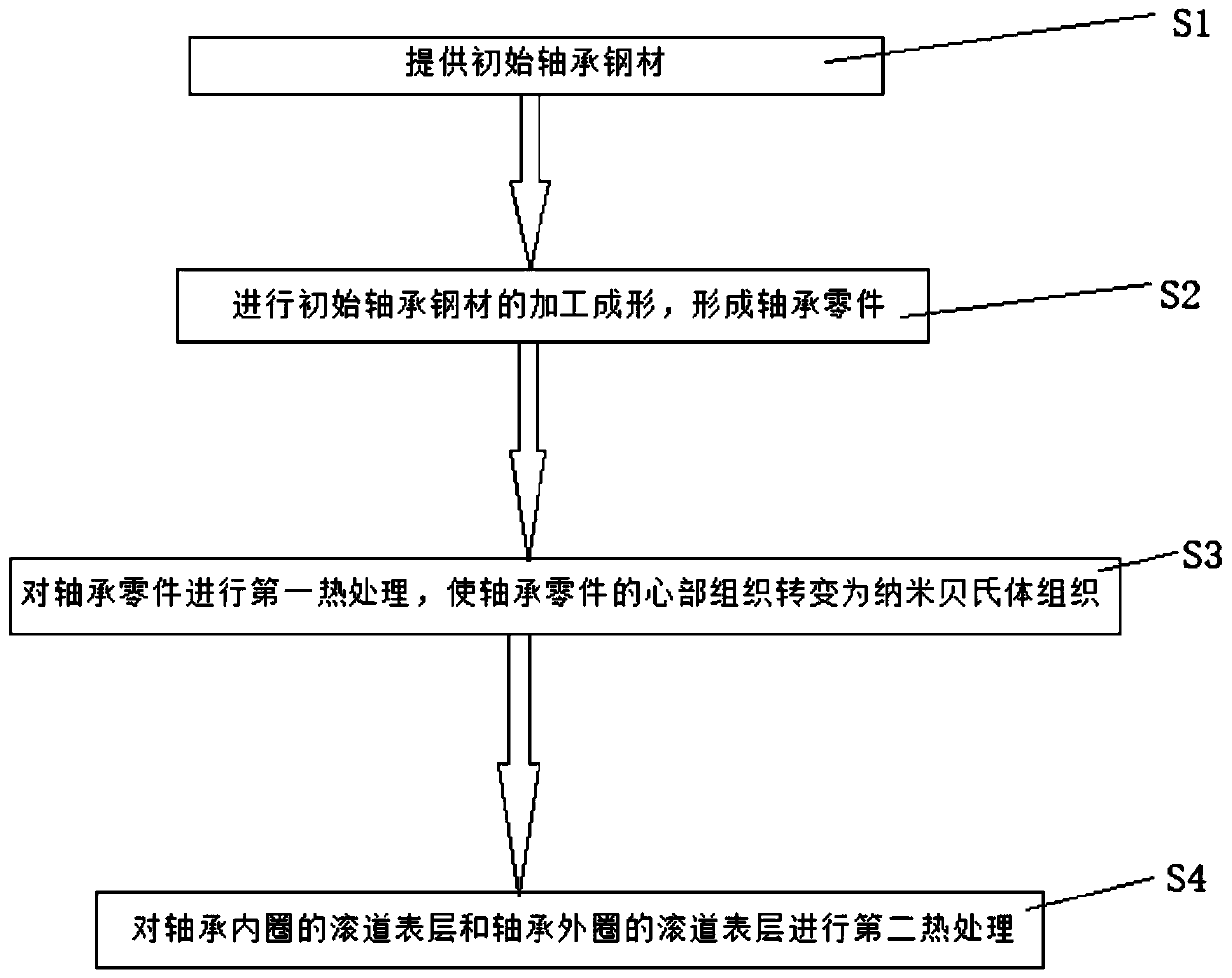

[0039] This embodiment provides a tissue regulation method for high-toughness bearings, including:

[0040] Step S1, providing the initial bearing steel, the chemical composition of the initial bearing steel includes: C: 0.70-0.75, Si: 1.50-2.90, Mn: 0.60-0.80, Cr: 0.60-1.60, Ni: 0-0.30 in terms of mass percentage , Mo: 0~0.40, S: ≦0.010, P: ≦0.015, O: ≦0.0008, Ti: ≦0.003, H: ≦0.00015, and the rest are Fe and unavoidable impurities.

[0041] In this embodiment, the initial bearing steel material may be a steel ingot for processing into a bearing. Specifically, in terms of mass percentage, the chemical composition of the initial bearing steel includes: C: 0.73, Si: 2.20, Mn: 0.70, Cr: 1.42, Ni: 0.20, Mo: 0.30, S: 0.005, P: 0.007, O: 0.0004, Ti: 0.002, H: 0.00008, and the rest are Fe and unavoidable impurities.

[0042] Moreover, in this embodiment, annealing treatment such as spheroidizing annealing, soft annealing, etc. may also be performed on the initial bearing steel mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com