Structure of concrete delivery pump

A concrete conveying pump and concrete technology, applied in pumps, components of pumping devices for elastic fluids, piston pumps, etc., can solve problems such as failure to work normally, short life of hydraulic cylinders and conveying cylinders, and high energy consumption. Achieve the effect of overcoming short lifespan or even failure to work normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

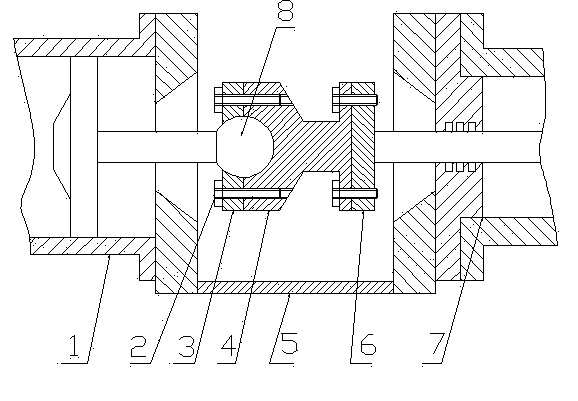

[0010] In the figure, the structure of the concrete Shusihong pump includes: feeding cylinder 1, bolt 2, spherical cover plate 3, ball head seat 4, water tank 5, flange 6, hydraulic cylinder 7, ball head 8, feeding cylinder 1 and the cylinder body of the hydraulic cylinder 7 are symmetrically installed and fixed on both sides of the water tank 5, a ball head 8 is fixed at the end of the piston rod of the feeding cylinder 1, and a flange is fixed at the end of the piston rod of the hydraulic cylinder 7 6. The ball head 4 is set between the ball head 8 and the flange 6, wherein the ball head 8 sinks in the ball socket on the ball head seat 4, and the ball head 8 is fixed on the Together, the other end of the ball head seat 4 is fixedly connected to the flange 6 with bolts 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com