High-temperature thermal transfer decoration method for abrasion-resistant aluminum honeycomb panel of rail transit interior decoration and product

A technology of rail transit and aluminum honeycomb, which is used in the field of aluminum products, can solve problems such as insufficient wear resistance of decorative layers, and achieve the effect of clear patterns, convenient maintenance, and improvement effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

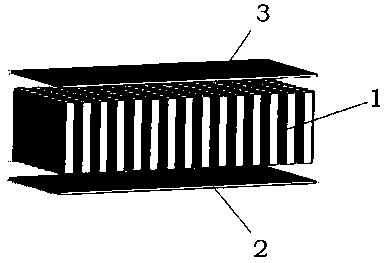

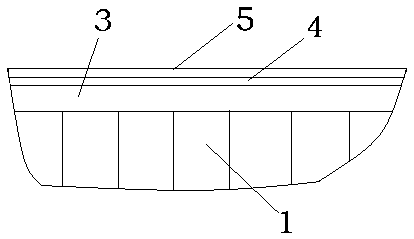

[0029] by attaching figure 1 with 2 It can be seen that the present invention relates to a high-temperature heat-transfer decorative profile of a wear-resistant aluminum honeycomb panel for interior decoration of rail transit, including an aluminum honeycomb panel core 1, a lower panel 2 and an upper panel 3, and a foundation is compounded on the outer surface of the upper panel 3 Resin 4, the surface of the foundation resin is compounded with a wood grain decorative layer 5.

[0030] The aluminum honeycomb panel core 1 and the upper panel 3 are firstly welded by an intermediate frequency inverter DC welding machine to the middle joint part of the aluminum honeycomb panel core 1 and the upper panel 3, and then the aluminum honeycomb panel core and the periphery of the panel are welded by brazing The aluminum honeycomb panel is made by combining spot welding and brazing.

[0031] Described foundation resin 4 is by high-voltage electrostatic spraying, and foundation resin mate...

Embodiment 2

[0046] The basic method of embodiment two is the same as that of embodiment one, except that the electrostatic enhancing medium used is other modified cellulose, including carboxymethyl cellulose, methyl cellulose, hydroxypropyl methyl cellulose and ethyl One or any combination of two or more celluloses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com