Biomass polyester short fiber and preparation method thereof

A polyester staple fiber and biomass technology is applied in the field of biomass polyester staple fiber and its preparation. Conservation and sustainable development, ensuring high quality and stability, improving the effect of dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

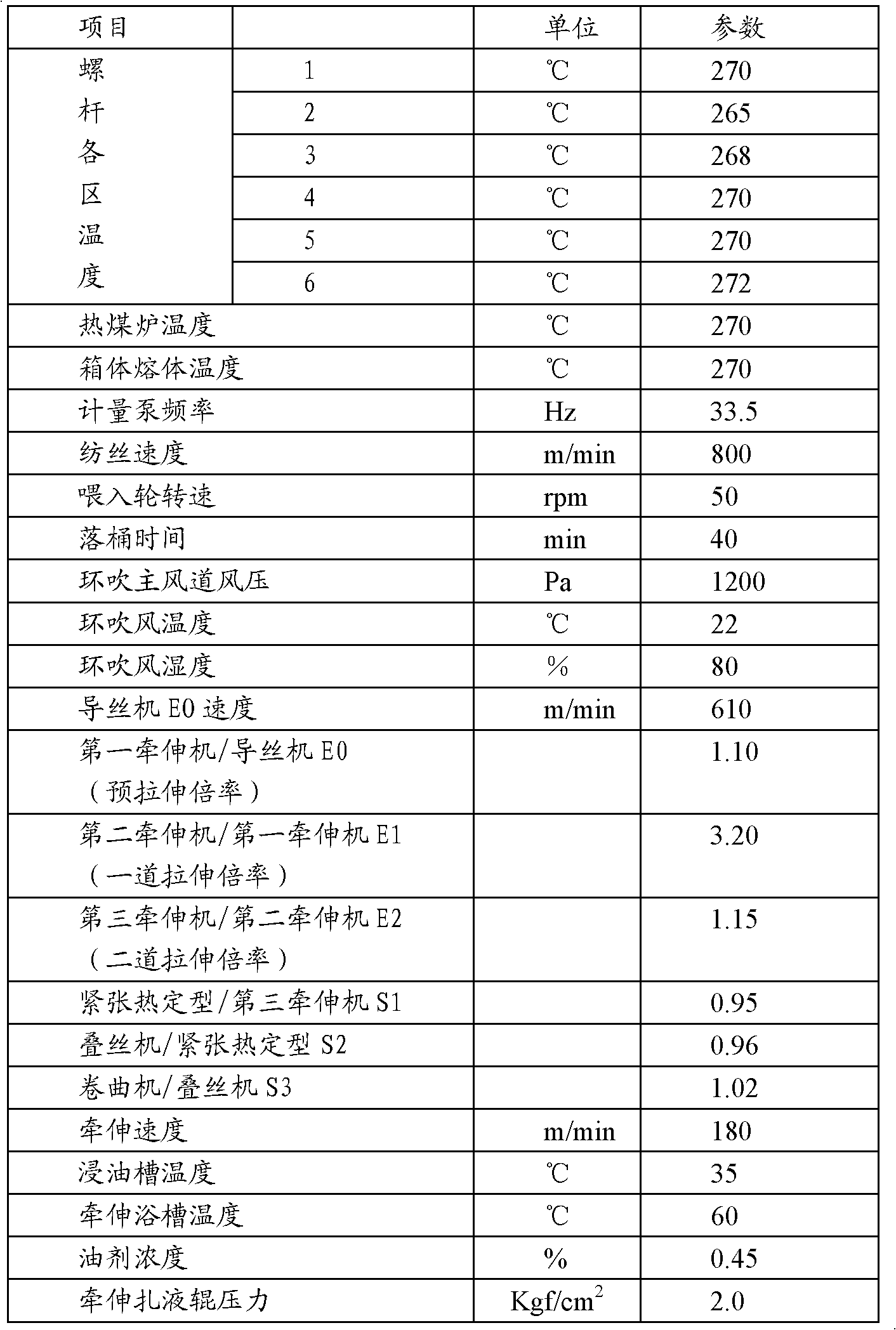

Embodiment 1

[0031] The raw material biological polyester PDT is produced by a continuous polymerization process, that is, terephthalic acid and biomass multi-component polyols are prepared into a slurry at a molar ratio of 1:1.05, and after esterification and polycondensation reactions, biomass Polyester (polyester PDT); Wherein, biomass multi-component polyol is made after fermentation of biomass industrial starch, and it comprises following weight ratio components: ethylene glycol 90wt%, 1,2-propanediol 5wt%, 1 , 2-butanediol 2wt%, pentanediol 2wt%, sorbitol 1wt%; the temperature of esterification reaction is 280 ℃, the relative pressure is 0.3MPa; Also add catalyst, heat stabilizer and antioxidant in the esterification reaction, wherein catalyst is titanium dioxide, add-on is 500ppm, heat stabilizer is antimony trioxide, add-on is 0.02wt%, antioxidant is antioxidant 1010, add-on is 0.03wt%, and the basis of the added amount of the catalyst, heat stabilizer and antioxidant is the mass o...

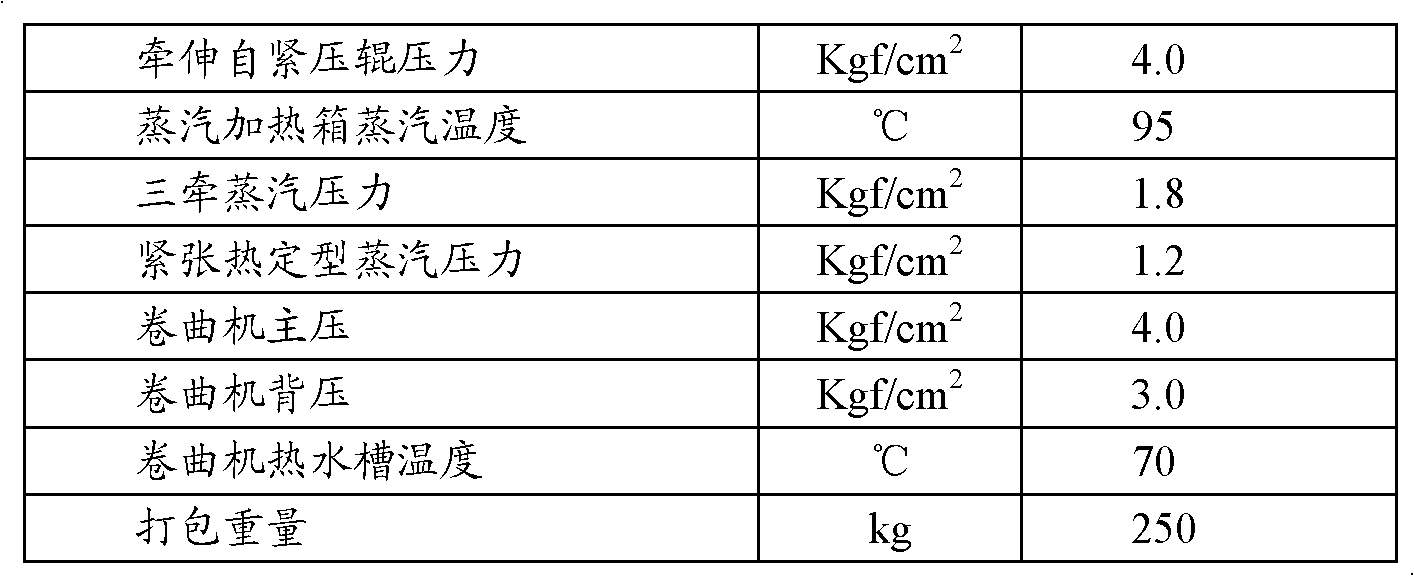

Embodiment 2

[0044] The raw material bio-polyester PDT is produced by continuous polymerization process, that is, terephthalic acid and biomass multi-component polyols are prepared into slurry according to the molar ratio of 1:1.5, and the biomass is obtained through esterification reaction and polycondensation reaction. Polyester; Wherein, biomass multi-component polyol is made after fermentation of biomass industrial starch, and it comprises following weight ratio components: ethylene glycol 99.2wt%, 1,2-propanediol 0.4wt%, 1,2- 0.2wt% butanediol, 0.1wt% pentylene glycol, 0.3wt% sorbitol; the temperature of the esterification reaction is 225°C, and the relative pressure is 0.1MPa; the temperature of the polycondensation reaction is kept at about 260°C, and the duration is 2h; the above Catalyst, heat stabilizer and antioxidant are also added in the esterification reaction, wherein adding catalyst is tetrabutyl titanate, and the addition is 120ppm, and heat stabilizer is alkyl phosphoric a...

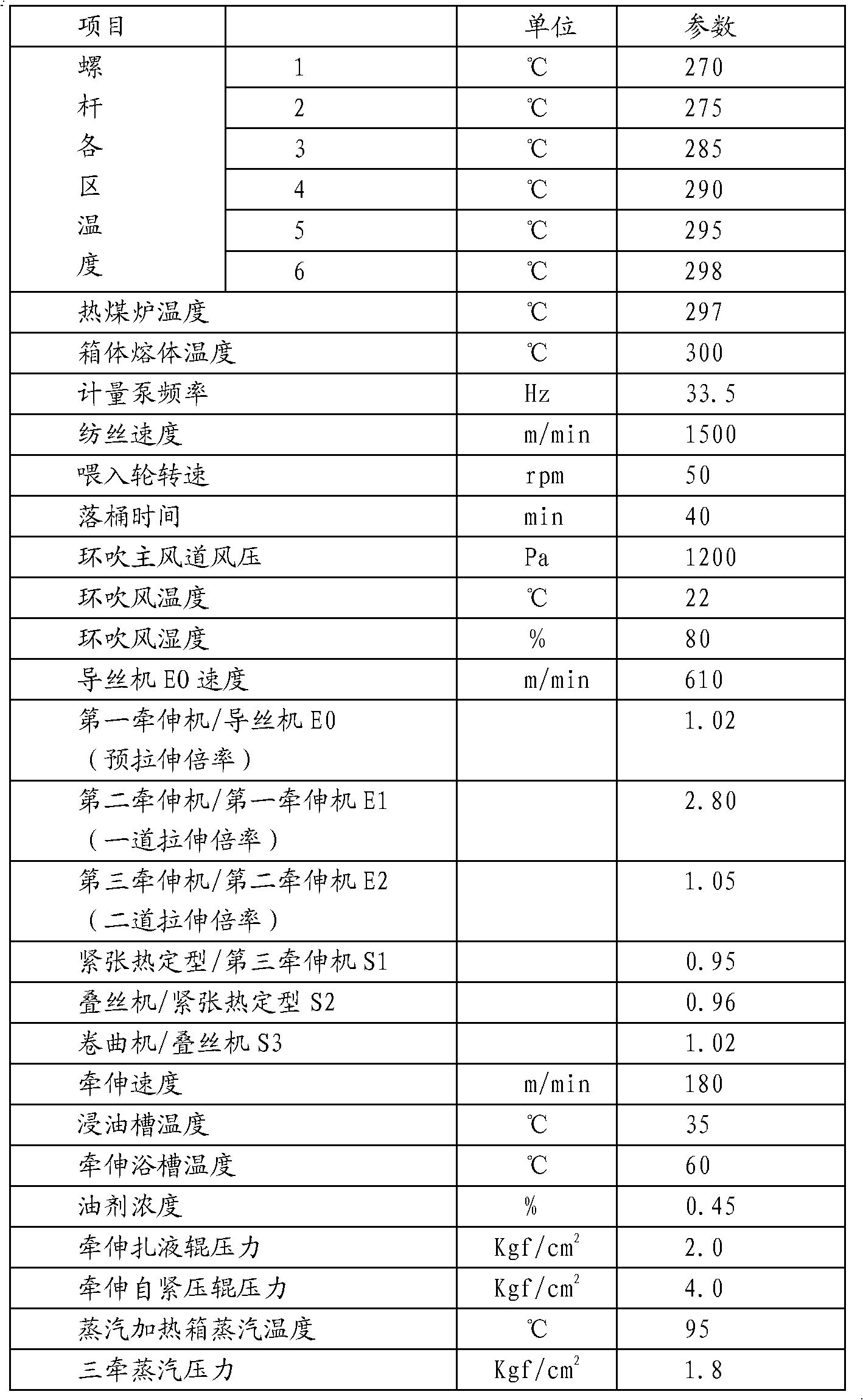

Embodiment 3

[0057] The raw material bio-polyester PDT is produced by a continuous polymerization process, that is, terephthalic acid and biomass multi-component polyols are formulated into a slurry at a molar ratio of 1:1.2, and the biomass is obtained through esterification and polycondensation reactions. Polyester; Wherein, biomass multi-component polyol is made after fermentation of biomass industrial starch, which includes the following components by weight: ethylene glycol 95wt%, 1,2-propanediol 3.1wt%, 1,2-butane 1wt% diol, 0.8wt% pentylene glycol, 0.1wt% sorbitol; the temperature of the esterification reaction is 225°C, and the relative pressure is 0.2MPa; the temperature of the polycondensation reaction is kept at about 260°C, and the duration is 3h; Also add catalyzer, heat stabilizer and antioxidant in the reaction, wherein add catalyzer and be antimony trioxide, add-on is 300ppm, heat stabilizer is trinonyl phenyl phosphite, add-on is 0.001wt%, and antioxidant is antimony trioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com