Textile setting and drying device

A technology for shaping drying and drying box, which is applied in textile and papermaking, textile material processing, textile material carrier processing, etc. Quality degradation and other problems, to improve drying quality, avoid aging and color changes in printing and dyeing, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

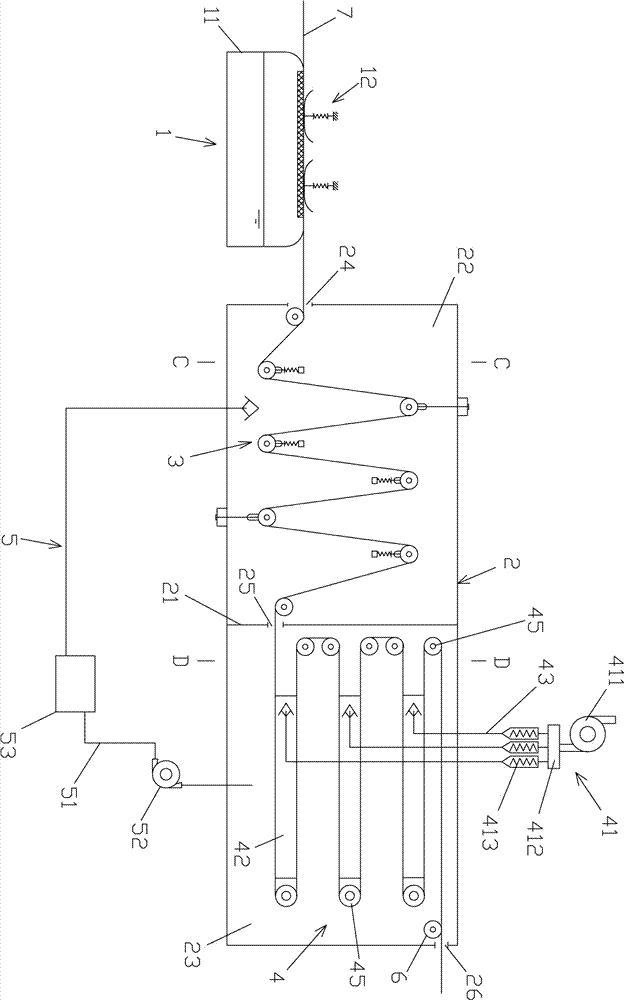

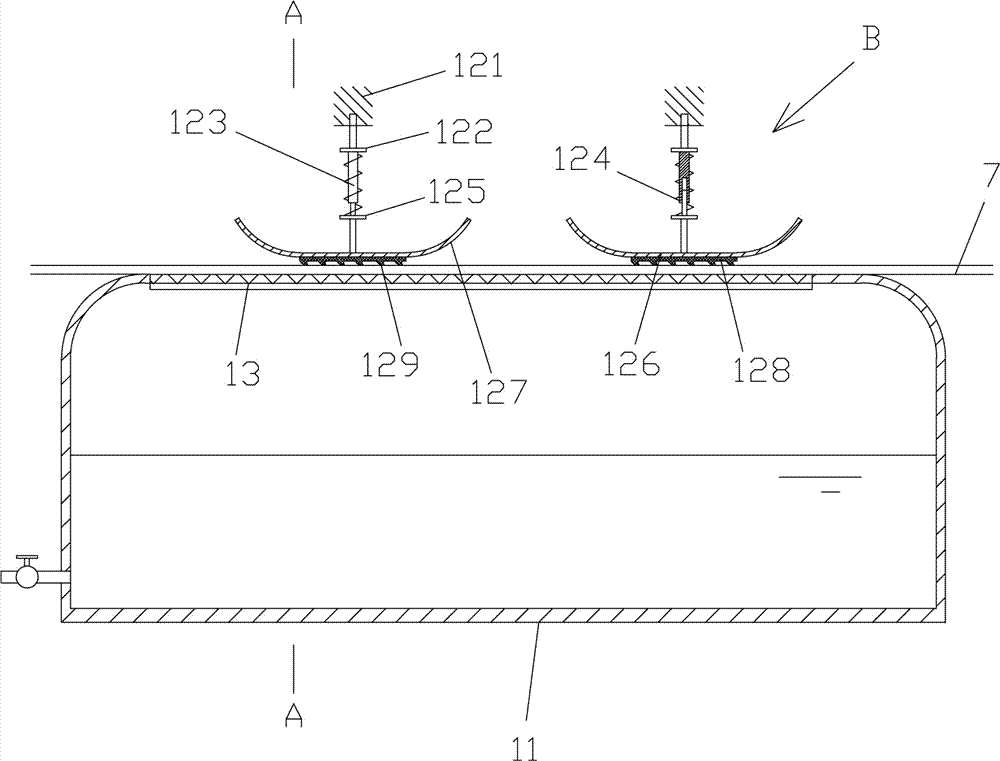

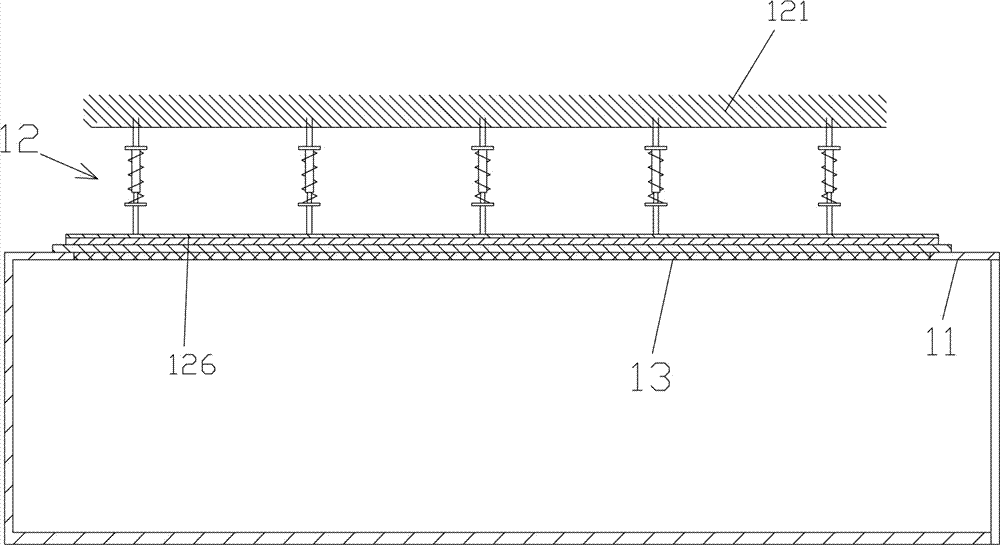

[0029] Such as figure 1 As shown, a drying device for textile sizing, comprising a water squeezing device 1 and a drying box 2 arranged on one side of the water squeezing device 1, a vertical partition 21 is arranged in the drying box 2, and the partition 21 divides the drying box 2 into a left cavity 22 and a right cavity 23, in the left cavity 22, a plurality of groups of cloth shaking mechanisms 3 are arranged in sequence, in the right cavity 23, a drying mechanism 4 is arranged, and in the drying box 2 two Cloth inlet 24 and cloth outlet 26 are respectively provided on the side, and cloth outlet 25 is provided on the partition 21; There is a guide roller 6; when using the present invention to carry out sizing and drying to the textile cloth, the textile cloth first passes through the water squeezing device 1 to remove water, then enters into the left cavity 22 through the cloth inlet 24, and then from the left cavity 22 From left to right, after each cloth shaking mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com