Pure cotton textile yarn dip dyeing process

A cotton textile and yarn technology, applied in the field of pure cotton textile yarn exhaust dyeing process, can solve the problems of slow efficiency, low efficiency, color deviation of dyed thread, etc., and achieve the goal of improving exhaust dyeing efficiency, increasing efficiency, and ensuring convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

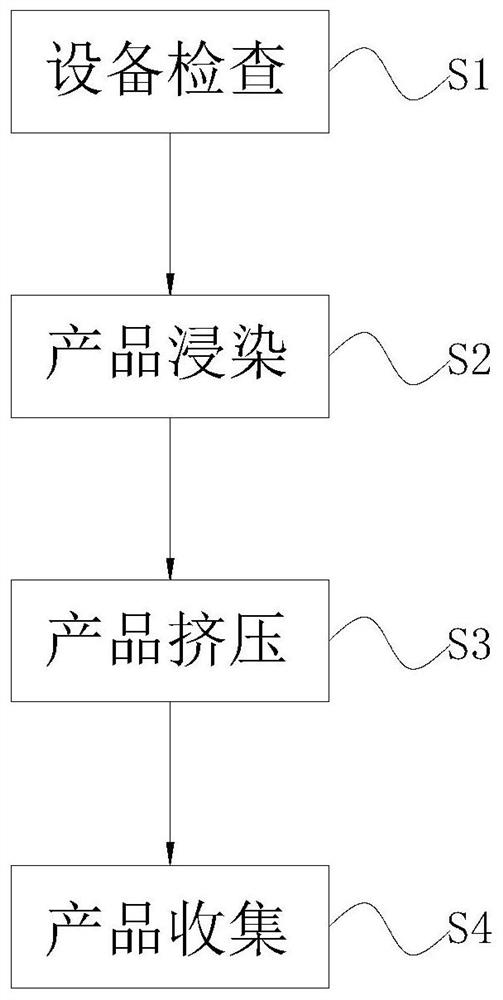

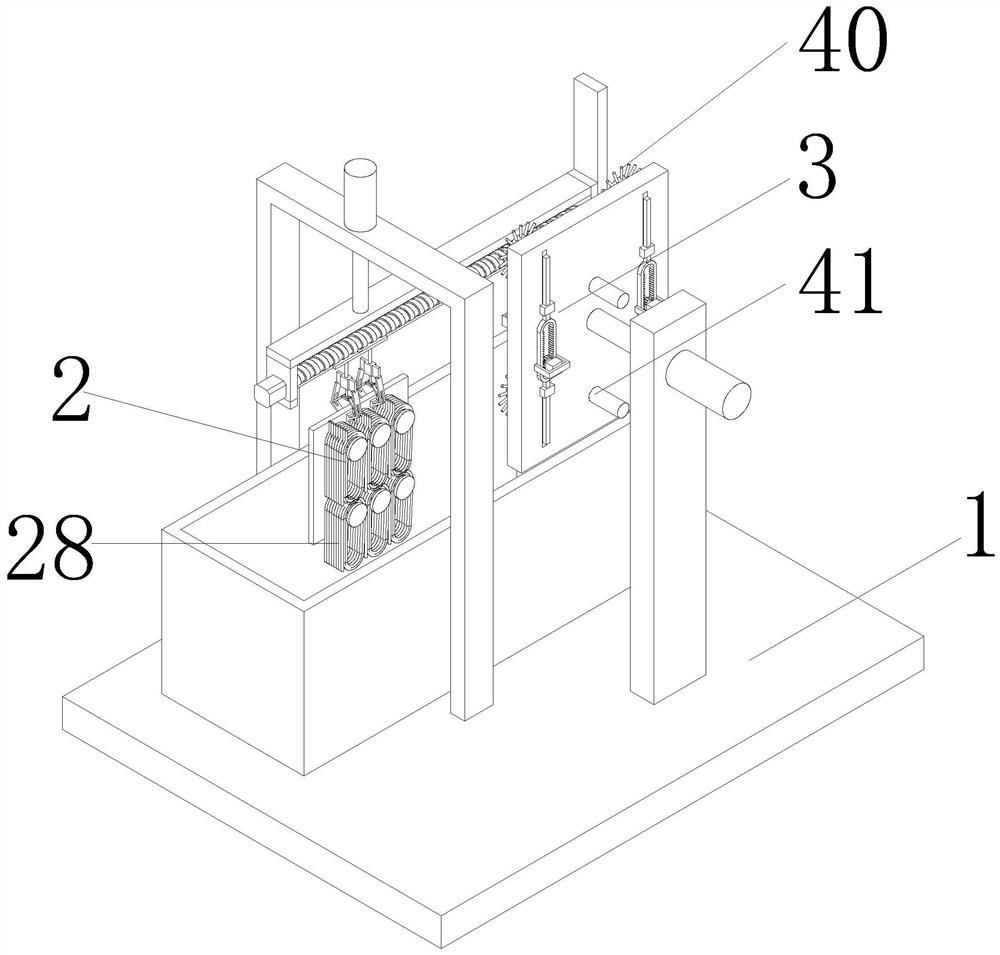

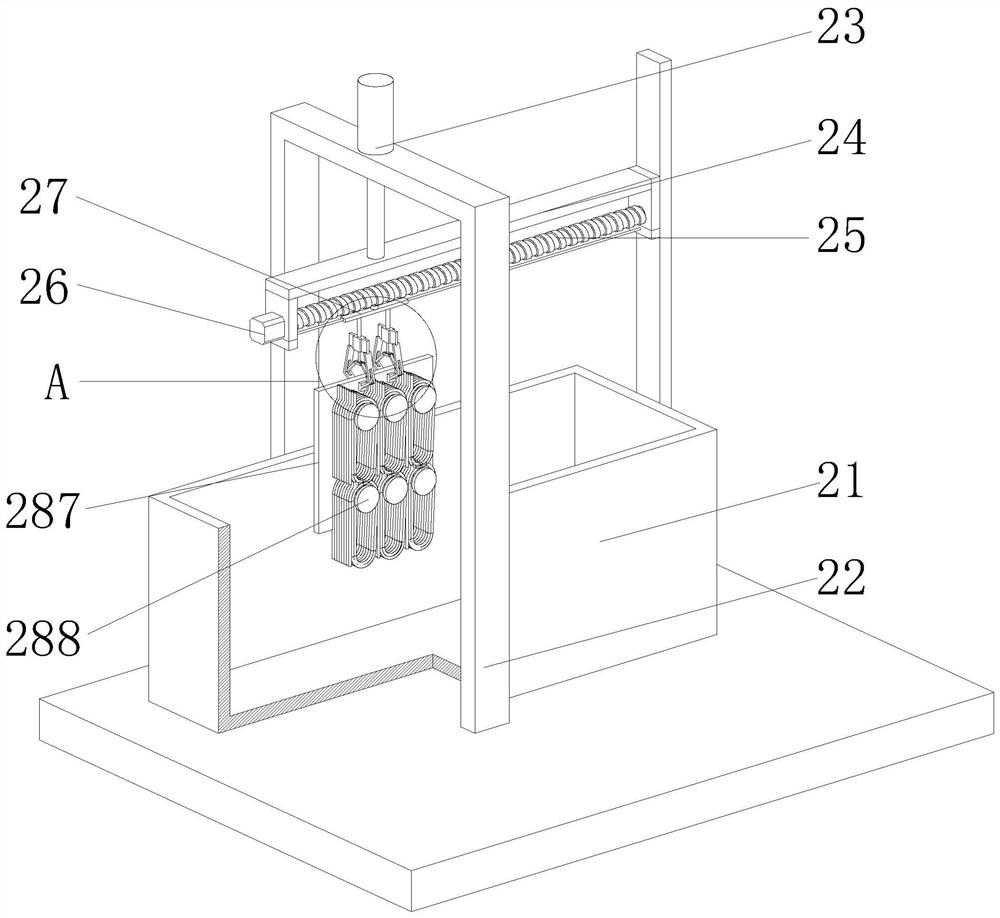

[0036] Such as Figure 1 to Figure 7As shown, a pure cotton textile yarn dip dyeing process, the pure cotton textile yarn dip dyeing process adopts the following pure cotton textile yarn dip dyeing equipment, the equipment includes a bottom plate 1, a dip dyeing mechanism 2 and an extrusion mechanism 3, the A dipping mechanism 2 is fixedly installed on the bottom plate 1, and an extruding mechanism 3 is arranged on the extruding mechanism 2, and the extruding mechanism 3 is located above the dipping mechanism 2; Place the winding frame 288 on the plate 287 for fixing, then soak the pure cotton textile yarn to be processed into the special liquid for dyeing through the dipping mechanism 2, and then squeeze it through the squeezing mechanism 3 to soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com