Dying processing device for socks

A processing device and sock technology, which is applied in the processing of textile material equipment configuration, the removal of extruded liquid/gas/vapor except for the roller, and the processing of textile material carriers, etc., which can solve the problems of low efficiency, waste of dye solution, slow drying of socks, etc. problems, achieve the effect of reducing waste, high dyeing efficiency, and improving dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

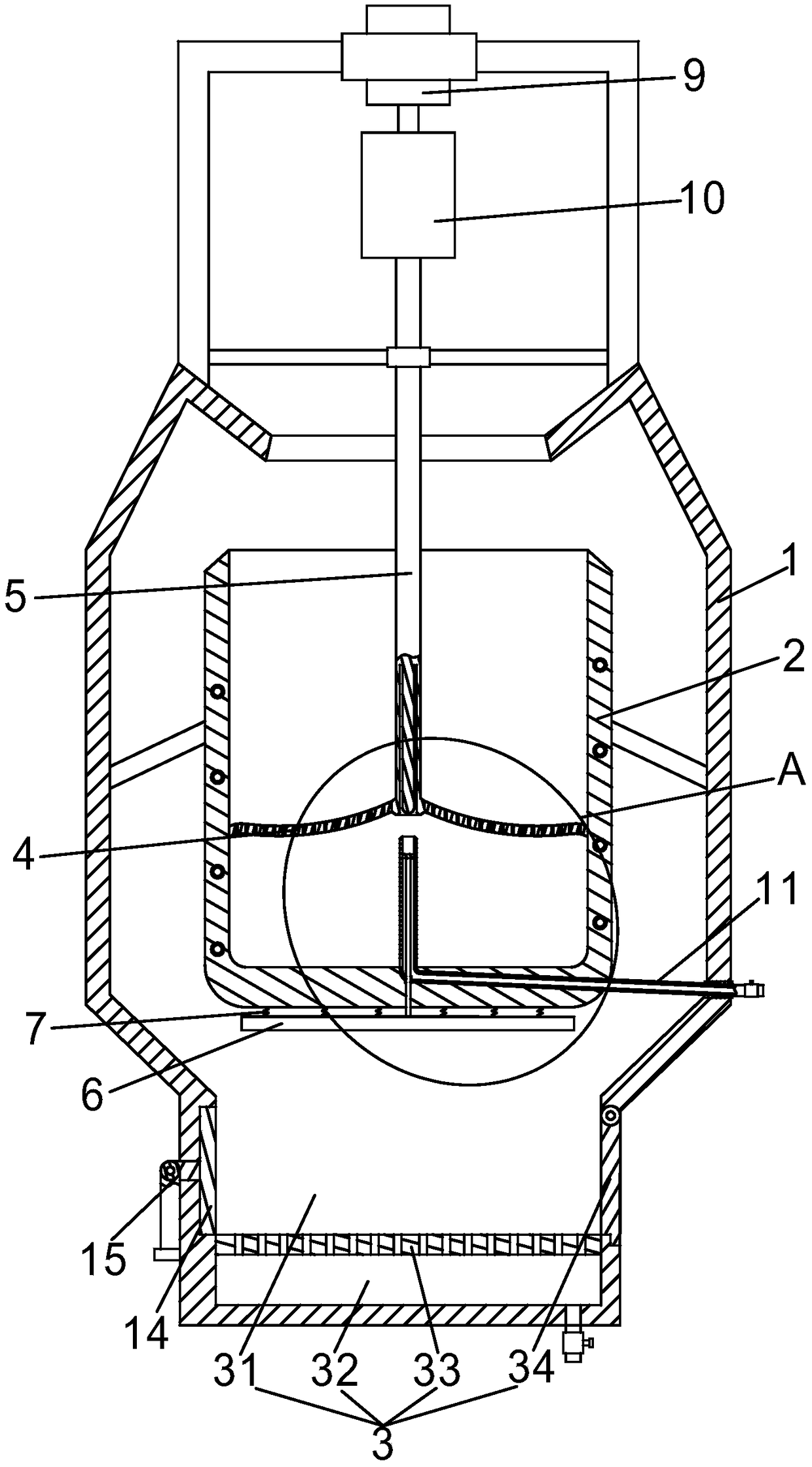

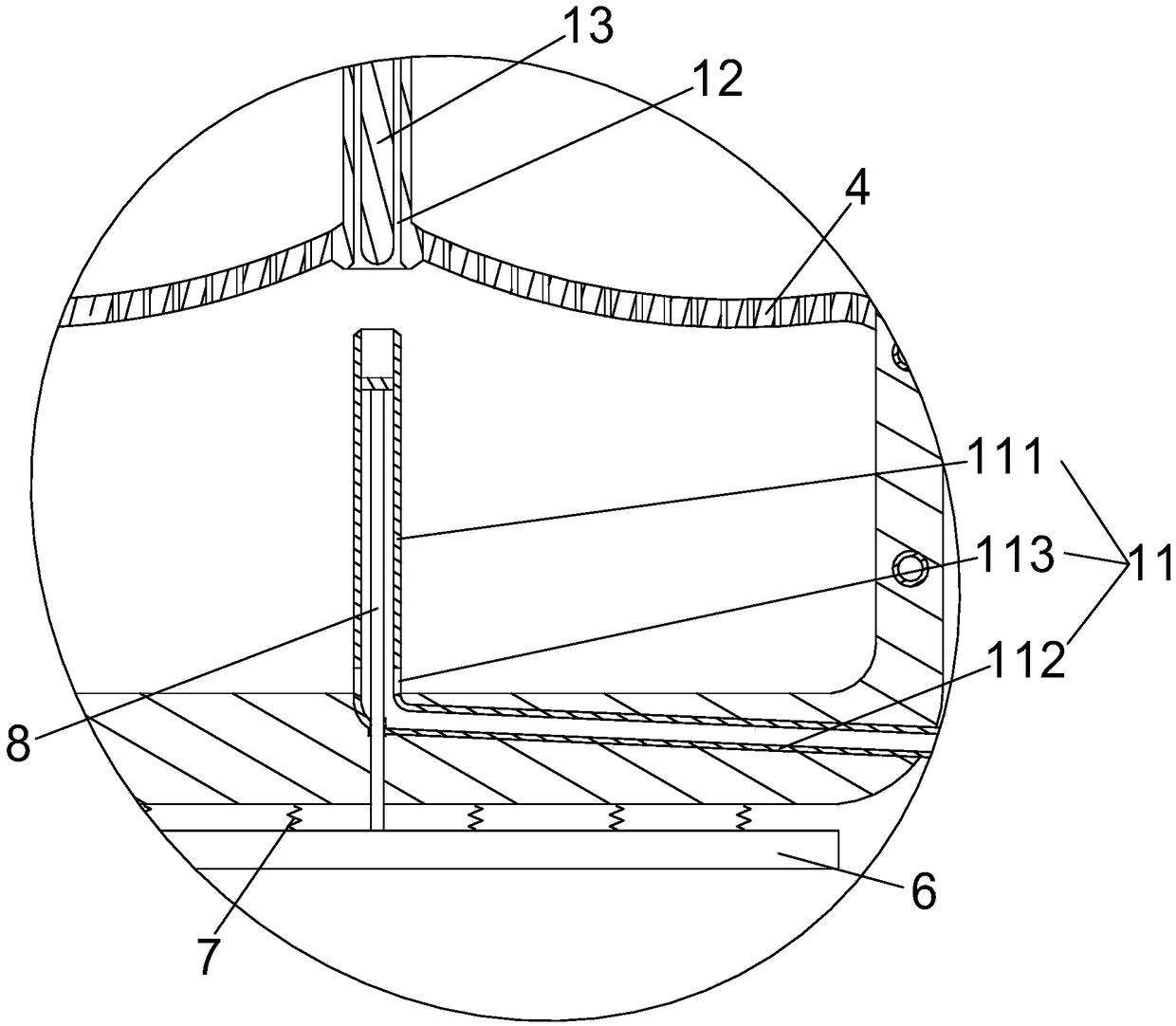

[0015] refer to figure 1 and figure 2 Shown: a dyeing processing device for socks, including a processing tank 1 with an open upper end, a dyeing tank 2 with an open upper end fixedly connected to the processing tank 1 through a number of support rods, the dyeing tank 2 is provided with a heater, and the processing tank 1 1. Located below the dyeing tank 2 is the extrusion filter chamber 3; the dyeing tank 2 is provided with a stirring filter 33 disks for rotation, and the stirring filter 33 disks are matched with a rotating lifting mechanism, which is used to drive stirring and filtering The net 33 discs rotate to dye the socks, and at the same time, lift and agitate the filter net 33 discs to the upper port of the dyeing tank 2 to rotate and throw the dyed socks into the extrusion filter chamber 3; The shaft 5 is connected to the agitating filter screen 33 discs, and the extruding filter chamber 3 is provided with an extruding plate 6 for extruding and separating the socks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com