Dyeing processing device for socks

A processing device and technology for socks, applied in the processing of textile materials, equipment configuration for processing textile materials, removal of extruded liquid/gas/steam except rollers, etc., can solve the problem of low dyeing efficiency of socks and achieve coloring Uniform, full contact, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

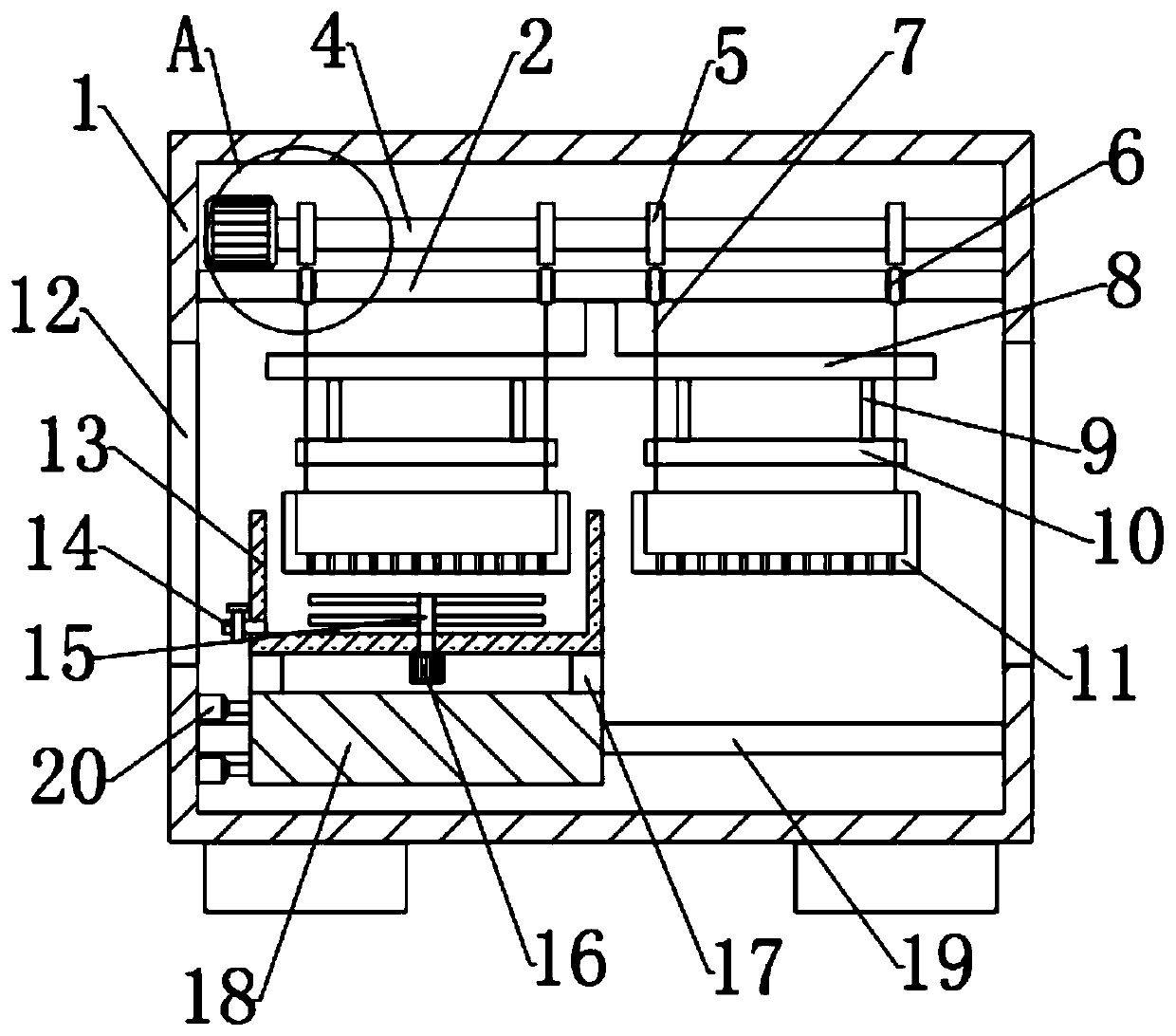

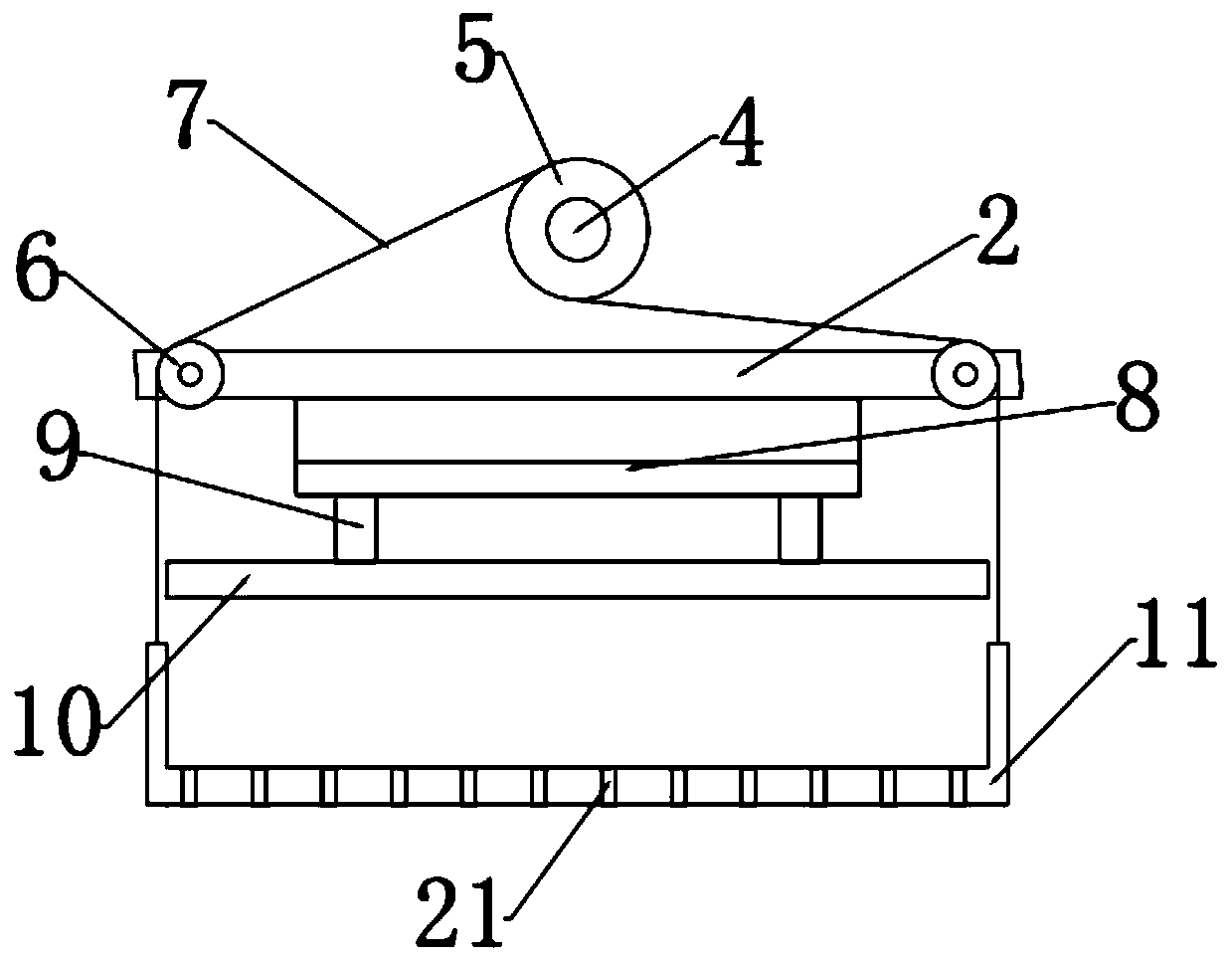

[0026] see Figure 1~3 , in an embodiment of the present invention, a dyeing processing device for socks includes a housing 1, the inside of the housing 1 is fixedly connected with a top plate 2, and the bottom of the top plate 2 is fixedly connected with a connecting plate 8, the A dyeing frame 11 is arranged on the lower side of the left and right ends of the connecting plate 8, and the dyeing frame 11 is connected with the driving mechanism arranged at the top of the top plate 2, and the dyeing box 13 is arranged on the lower side of the dyeing frame 11, and the bottom of the dyeing box 13 Connected with the moving mechanism, openings 12 are provided on the left and right sides of the casing 1 .

Embodiment 2

[0028] In this embodiment, the longitudinal section of the connecting plate 8 is a "T"-shaped structure.

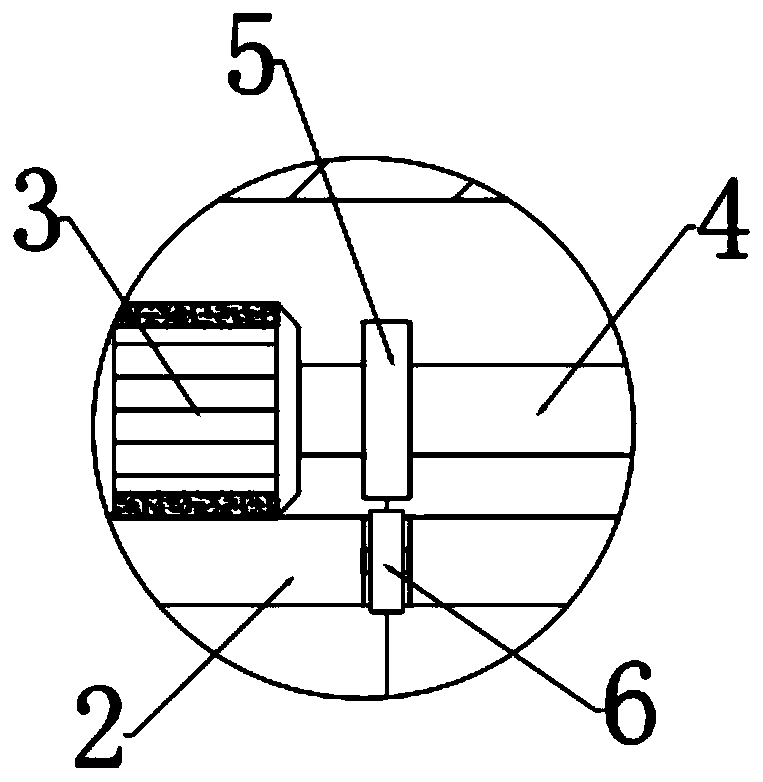

[0029] In this embodiment, the drive mechanism includes a first motor 3, a rotating rod 4, a runner 5 and a pull cord 7, and the first motor 3 is bolt-connected and arranged on the top of the top plate 2, and the output on the right side of the first motor 3 is The end is connected with the rotating rod 4, and the rotating rod 4 is fixedly connected with several runners 5, and the upper and lower sides of the runner 5 are fixedly connected with stay ropes 7, and the other ends of the stay ropes 7 on both sides are connected with the dyeing frame respectively. 11. The frame walls on both sides of the front and rear sides are fixedly connected. By setting the driving mechanism, the dyeing frames 11 on the left and right sides can be lifted and lowered at the same time, so that the dyeing frame 11 can fully contact with the dyeing box 13, and the dyeing frame 11 on one side c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com