Bleaching and wiping device

A technology of a squeezing device and a bleaching box is applied in the field of bleaching devices, which can solve the problems of trouble, low efficiency, water accumulation, etc., and achieve the effects of fast and uniform bleaching and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

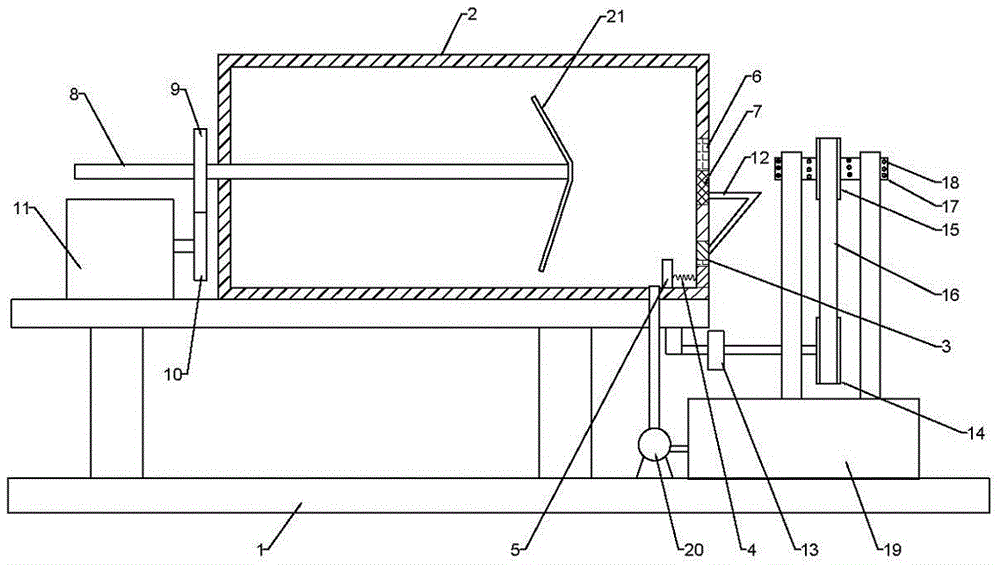

[0016] The reference signs in the drawings of the description include: frame 1, bleaching box 2, hinged plate 3, extension spring 4, vertical plate 5, upper rotating plate 6, lower rotating plate 7, rotating push rod 8, first gear 9, Second gear 10, motor 11, folding line 12, water wheel 13, first pulley 14, second pulley 15, belt 16, squeeze dry cylinder 17, filter hole 18, water tank 19, water pump 20, textile 21.

[0017] Example basic reference figure 1 As shown: the bleaching and squeezing device, including a frame 1 and a bleaching box 2, the bleaching box 2 is connected to the frame 1 by bolts, the left and right ends of the bleaching box 2 are respectively opened with a first through hole and a second through hole, the second through hole An internal thread is arranged in one through hole, and a through groove is opened on the wall of the bleaching box 2 below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com