Solid-liquid separation device and treatment equipment

A solid-liquid separation and cylinder technology, which is applied in dry cargo handling, lighting and heating equipment, drying solid materials, etc., can solve problems such as low production efficiency and poor solid-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

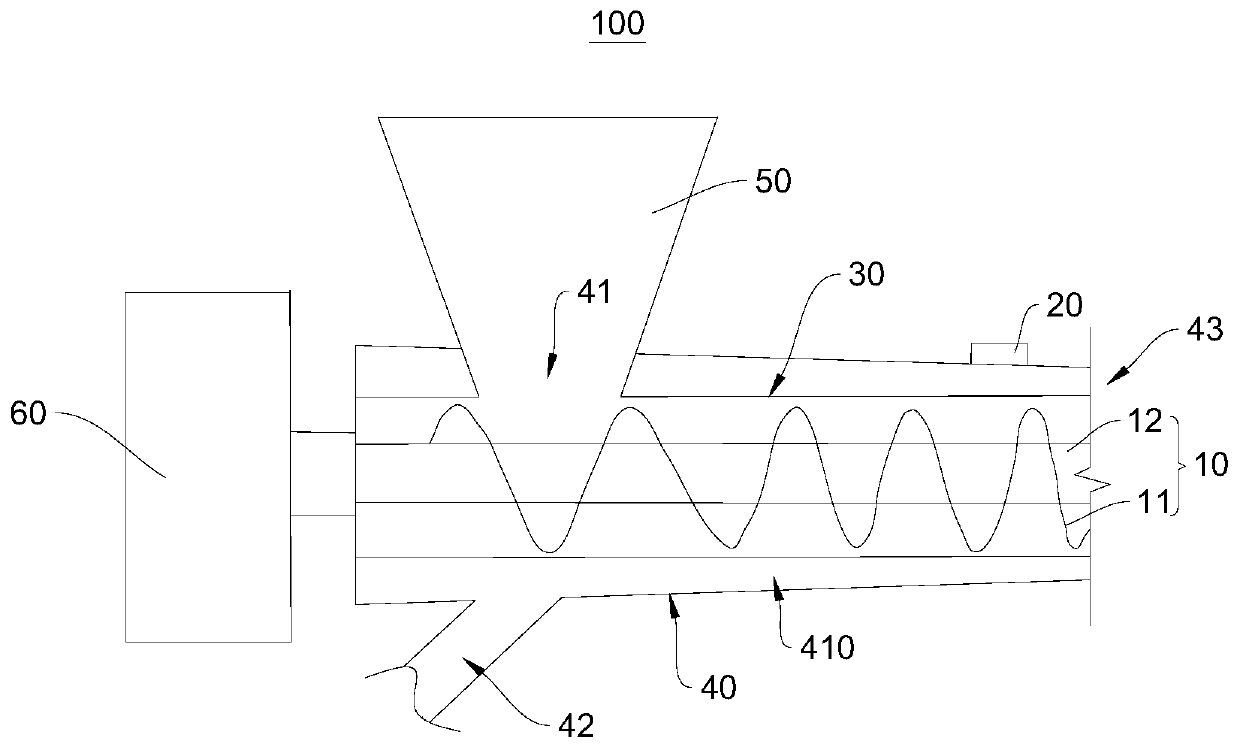

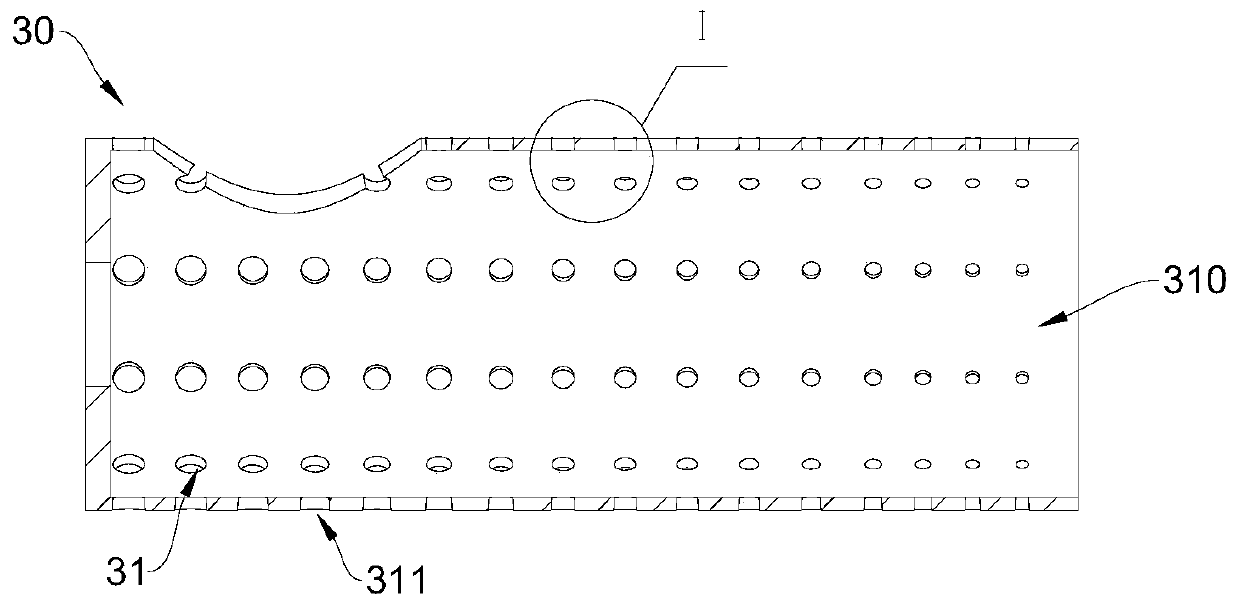

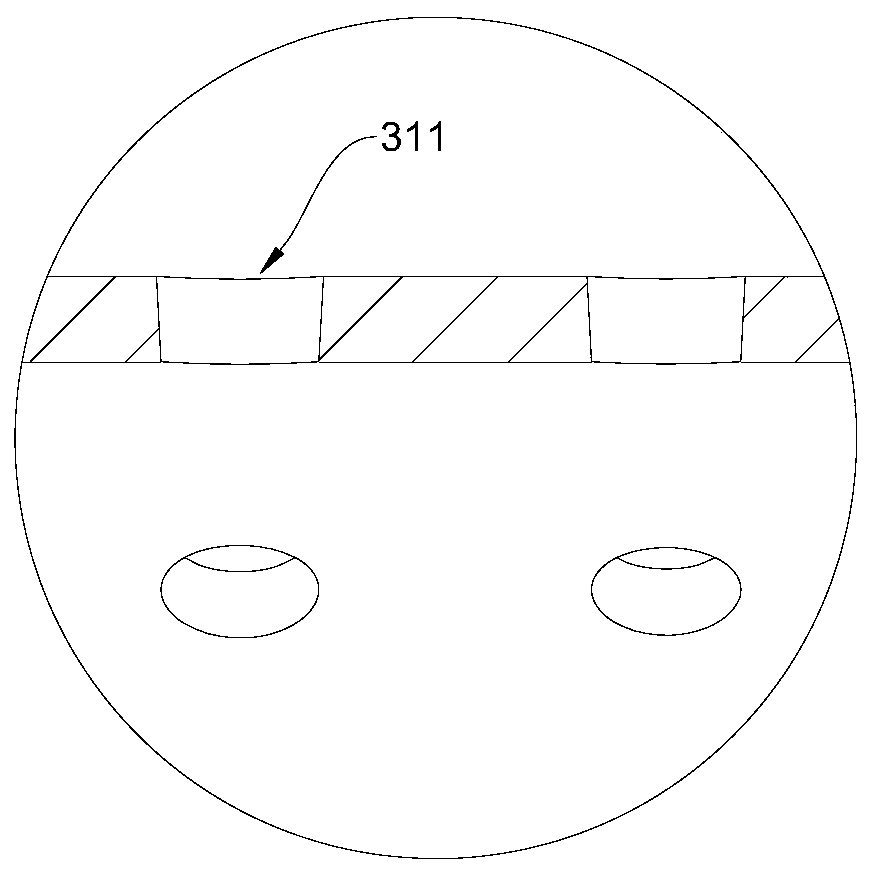

[0036] Please refer to figure 1 In this embodiment, a solid-liquid separation device 100 is provided, which includes a conveying member 10, a vibrating member 20, and a first cylinder 30 having a first chamber 310. The conveying member 10 is disposed in the first chamber 310, and The conveying member 10 is movably connected to the first cylinder 30. The conveying member 10 includes spirally arranged blades 11, which spirally extend along the axial direction of the first cylinder 30, and the pitch of the blades 11 is at the input of the first cylinder 30. The direction from the first barrel 30 to the output portion of the first cylinder 30 decreases, and the blades 11 are closely arranged with the inner wall of the first chamber 310, so that the material to be dehydrated from the input portion of the first cylinder 30 to the output of the first cylinder 30 Remove the water during the process.

[0037] It should be noted here that the blade 11 of the conveying member 10 and the inn...

Embodiment 2

[0061] This embodiment also provides a processing equipment, which includes the above-mentioned solid-liquid separation device 100, which has all the functions of the solid-liquid separation device 100, and the structure of the solid-liquid separation device 100 can refer to Embodiment 1.

[0062] It should be noted here that the processing equipment also includes other devices for processing crop stalks. The solid-liquid separation device 100 is used to dehydrate and output the crushed materials to be dehydrated, and the output materials enter the subsequent processing device for processing. Other processing.

[0063] In summary, the present invention provides a solid-liquid separation device 100, which can improve the dehydration efficiency of solid residues and moisture, and reduce the labor intensity of workers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com