Efficient wringing machine

A water squeezer, high-efficiency technology, applied in the direction of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc., can solve the problems that affect the harmless treatment process of garbage and low efficiency, and achieve continuous and uninterrupted extrusion The effect of improving the efficiency of press dehydration and extrusion dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

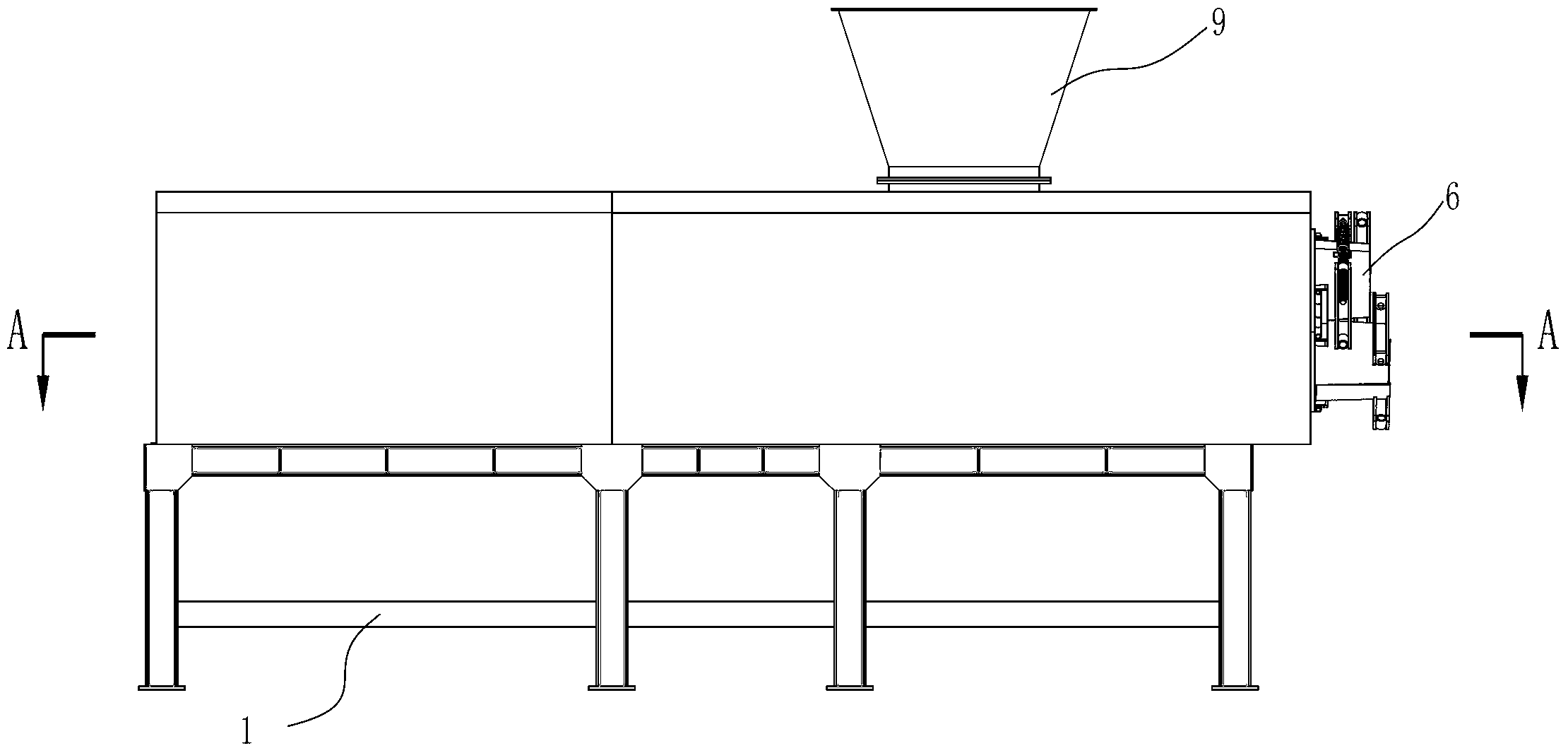

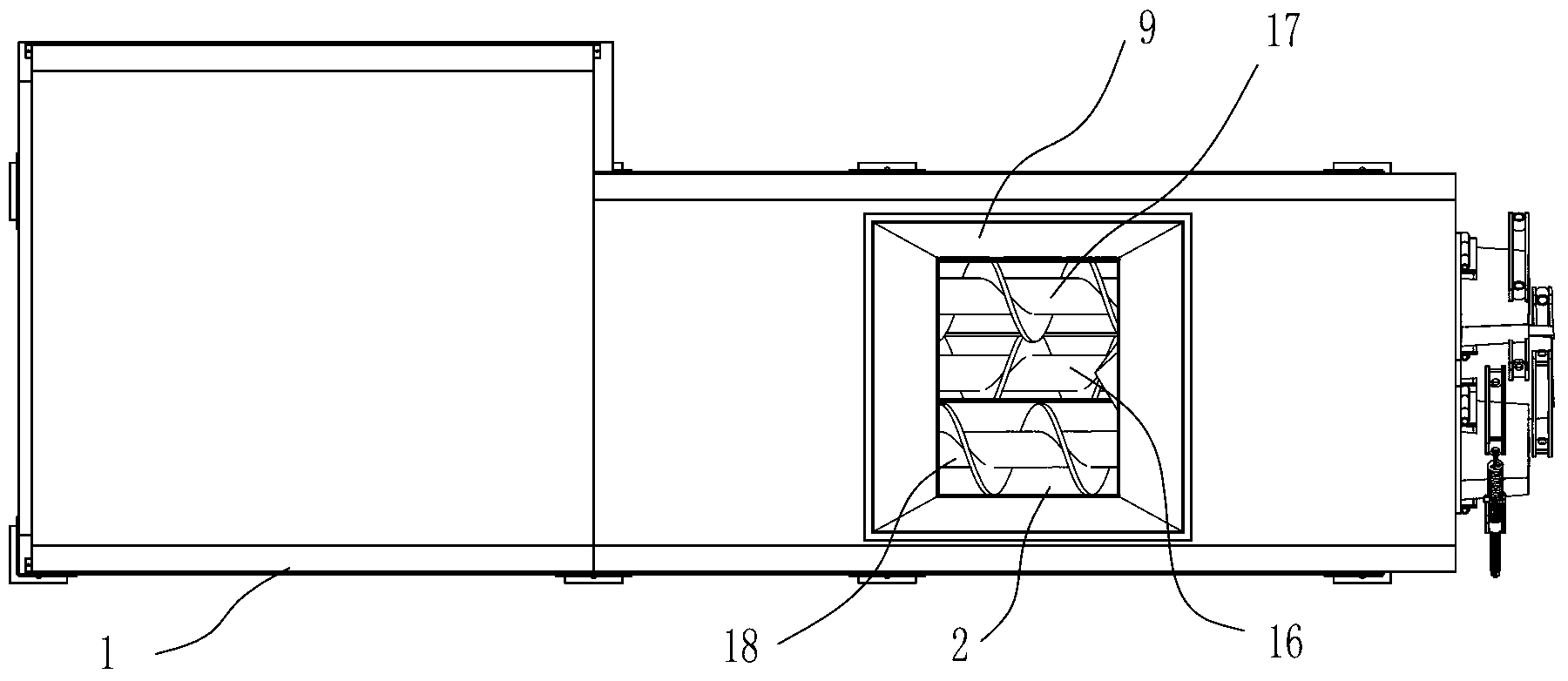

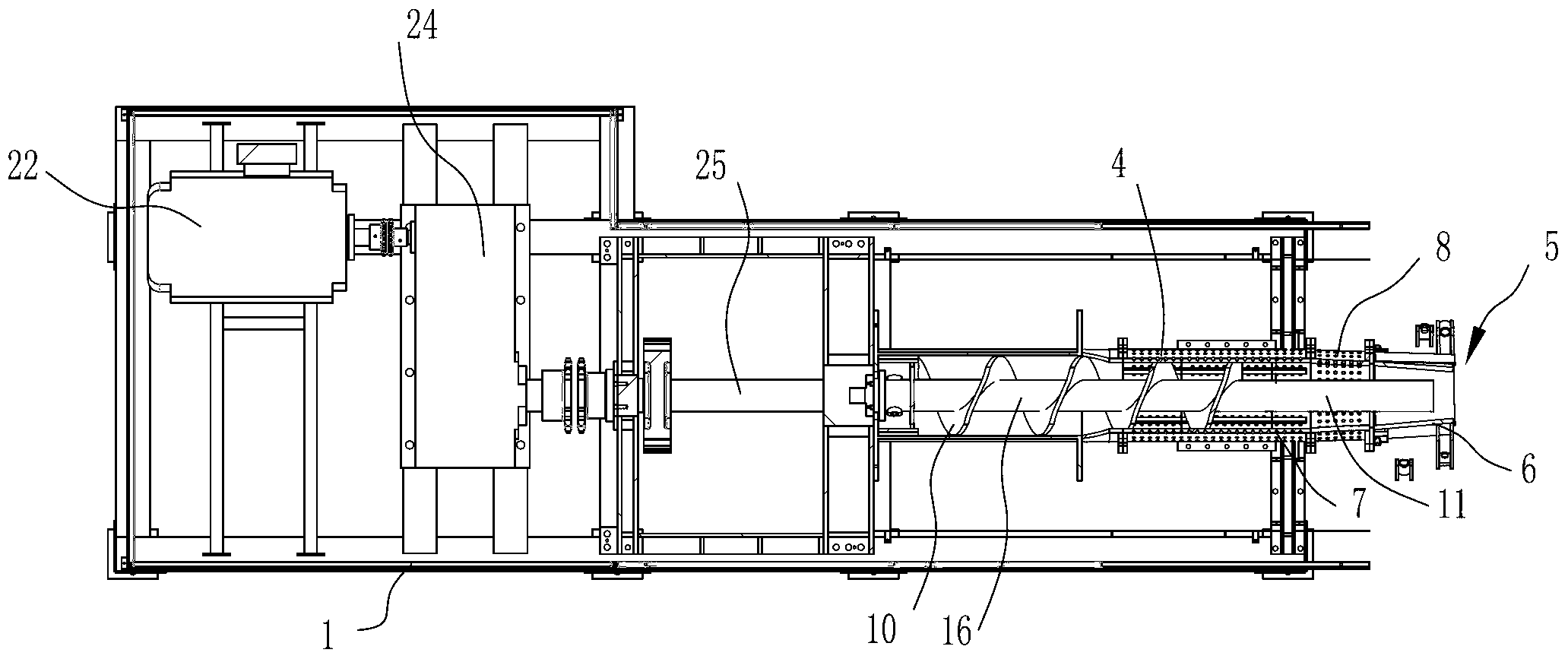

[0019] Such as figure 1 , figure 2 with Figure 4 As shown, the high-efficiency water squeezer includes a frame 1, the frame 1 is provided with a feed box 2, the feed box 2 is provided with a feed port 9, and the front end of the feed box 2 is provided with There are at least two discharge cylinders 3, and a screw extrusion device arranged in the feed box and the discharge cylinder, the screw extrusion device is connected with an extrusion driving device, and the front end of the discharge cylinder 3 is provided with The dehydration cylinder 4, the front end of the dehydration cylinder 4 is provided with a closing tube 5, the closing tube 5 realizes the discharge and extrusion dehydration at the same time, which greatly improves the extrusion dehydration efficiency, and the closing tube 5 includes at least two petals There are 6 flaps, a closing adjustment device is provided between the petals 6, and a water outlet hole 7 is provided on the dehydration cylinder 4.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com