Integrated equipment for pulping and solid-liquid separation for the solid phase of organic waste

A solid-liquid separation and organic waste technology, applied in the direction of solid waste removal, etc., can solve the problems of equipment wear, circulation pump failure, high cost, etc., to reduce manufacturing and use costs, solve easy damage and blockage, and reduce pretreatment required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

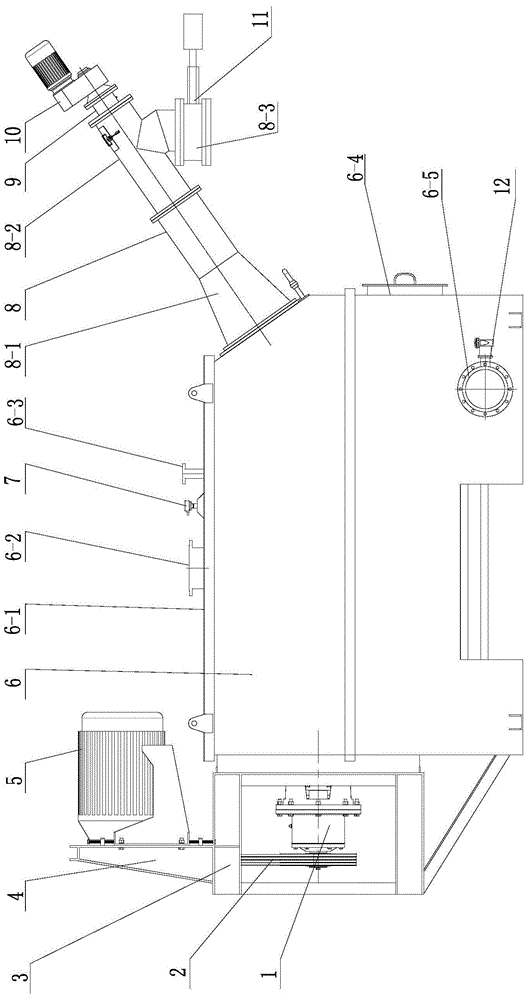

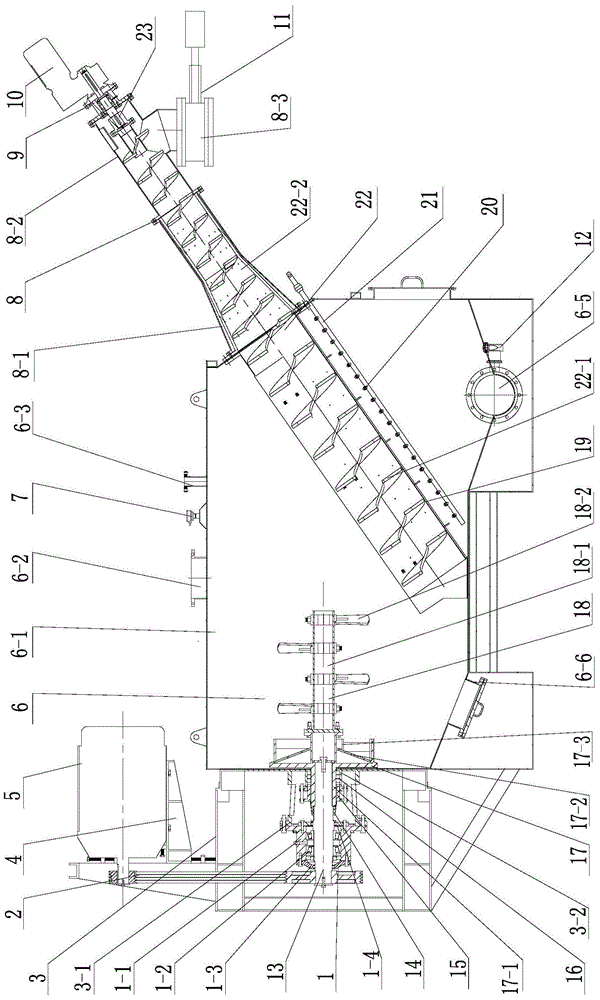

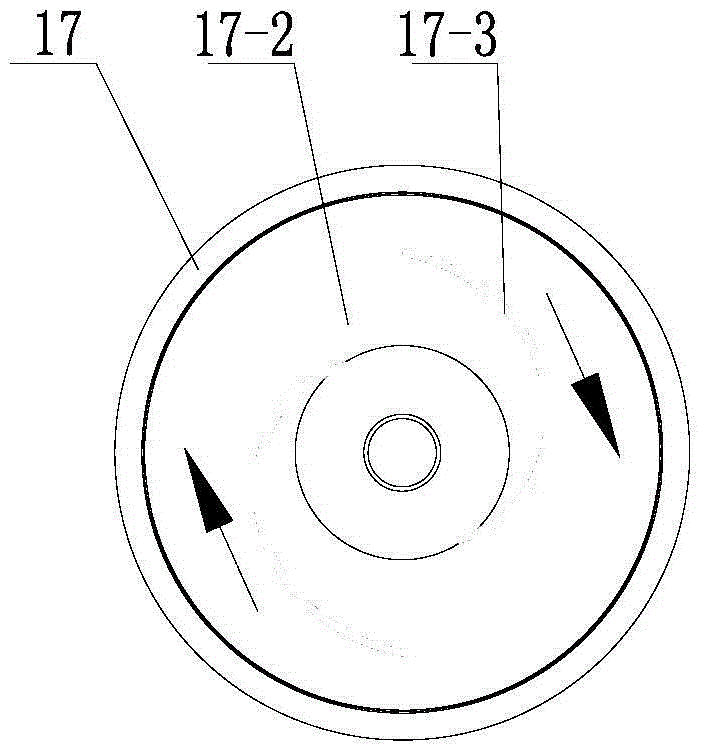

[0035] See figure 1 , 2 As shown, the integrated equipment for pulping and solid-liquid separation of organic waste in the present invention includes a casing 6 , a power transmission mechanism 2 and a pulping actuator arranged in the casing 6 .

[0036] See figure 1 , 2 As shown, the top cover 6-1 of the casing 6 of the present invention is provided with a feed inlet 6-2 and a water inlet 6-3, and the lower part of the fuselage is provided with a pulp outlet 6-5, and the pulp outlet 6-5 is A slurry discharge valve 12 is installed to control the opening and closing of the slurry discharge and the slurry discharge speed through the slurry discharge valve 12. The feed port 6-2 is used for the entry of the solid phase of organic waste, and the water inlet 6-3 is used for the entry of water. The feeding port 6-2 and the water inlet 6-3 of the present invention are located at the middle part of the top cover 6-1, and the solid phase of organic waste and a certain amount of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com