Hot air drying device

A technology of hot air drying and tuyere, which is applied in drying gas arrangement, garbage drying, biomass drying, etc., can solve the problems of raw material utilization of gasifier, high moisture content of agricultural and forestry waste or domestic waste, and increase of processing cost, etc. It is easy to dry, is conducive to full contact, and has the effect of increasing calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

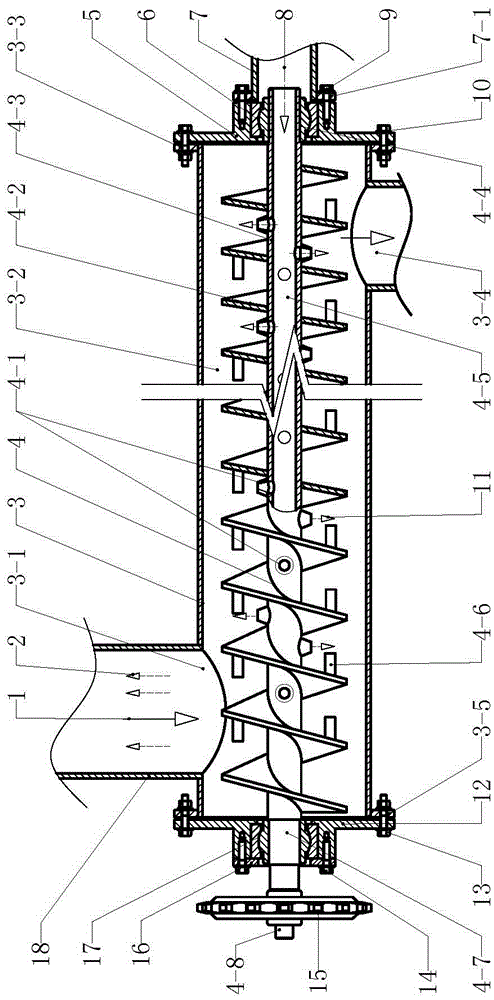

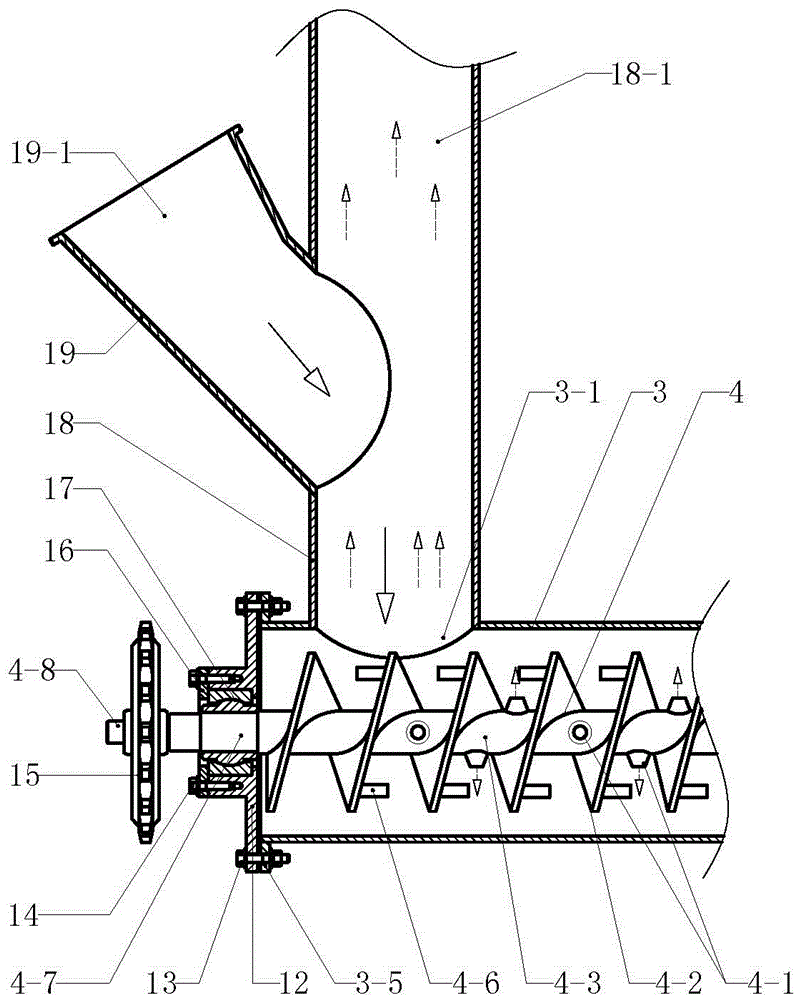

[0013] Example 1 figure 1 and figure 2 In the shown embodiment, the hot air drying device is composed of an auger 4, a housing 3 and an air extraction pipe 18, wherein the auger 4 is composed of a rotating shaft and a spiral stirring plate, and there are transmission joints 4 on the rotating shaft from front to back. -8, the front shaft head 4-7, the hollow shaft body 4-3 and the rear shaft head 4-4, the spiral stirring plate 4-2 surrounds the outside of the wall body of the hollow shaft body 4-3 in a spiral manner, and the spiral stirring plate The plate 4-2 is connected to the wall of the hollow shaft body 4-3 by welding, and there are stirring rods 4-6 arranged at intervals on the spiral stirring plate 4-2, and the stirring rods 4-6 are connected to the screw by welding. On the wire stirring plate 4-2, the inner space of the hollow shaft body 4-3 constitutes the air chamber 4-5, and the air inlet of the air chamber 4-5 is formed by the axial through opening at the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com