Efficient centrifugal dehydrator and method

A centrifugal dehydrator and high-efficiency technology, applied in dryers, non-progressive dryers, drying solid materials, etc., can solve problems such as environmental problems and diseases, inconvenient dumping, ecological damage, etc., and achieve fast and efficient dehydration treatment. , to avoid relative wear, the effect of reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

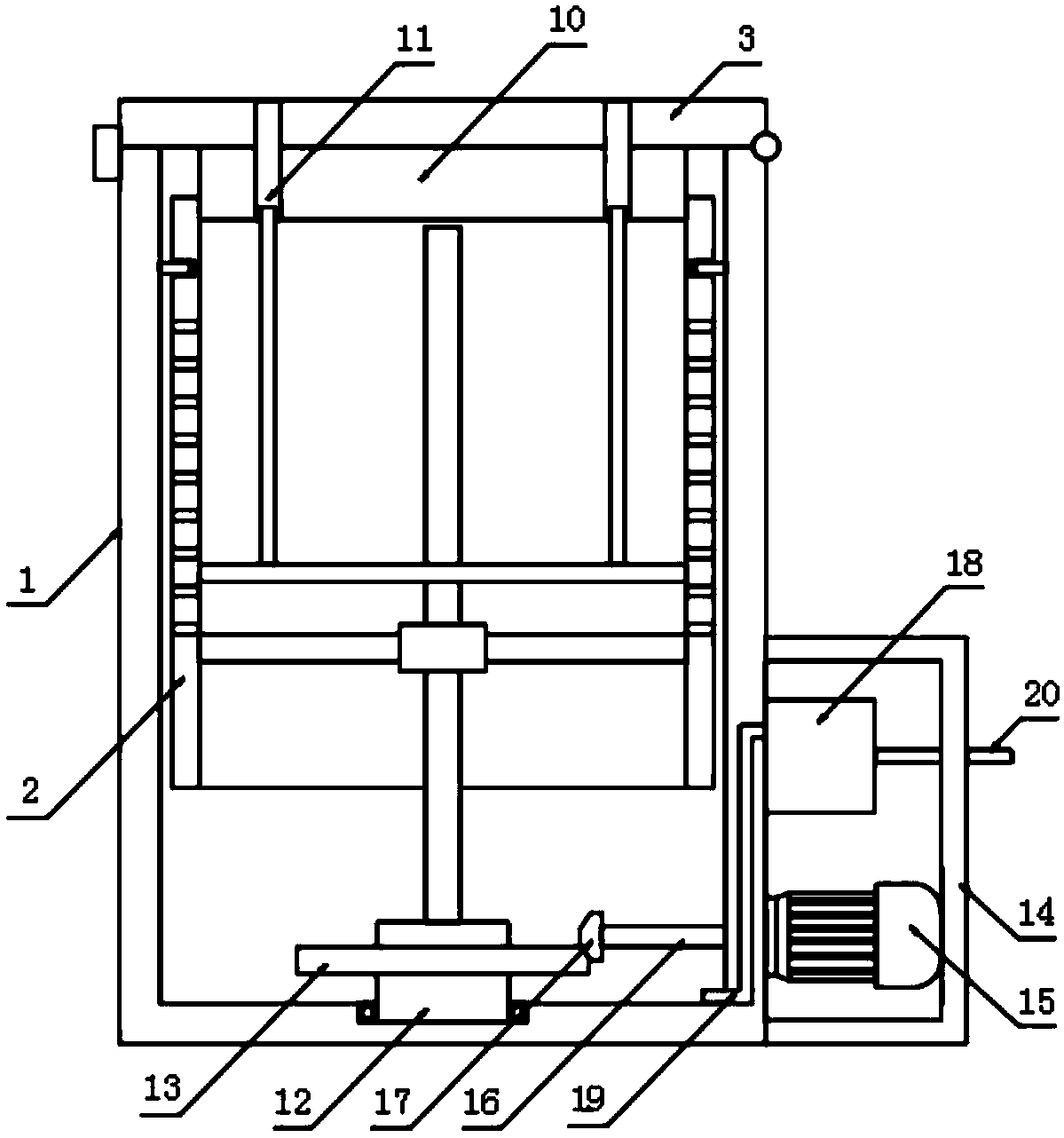

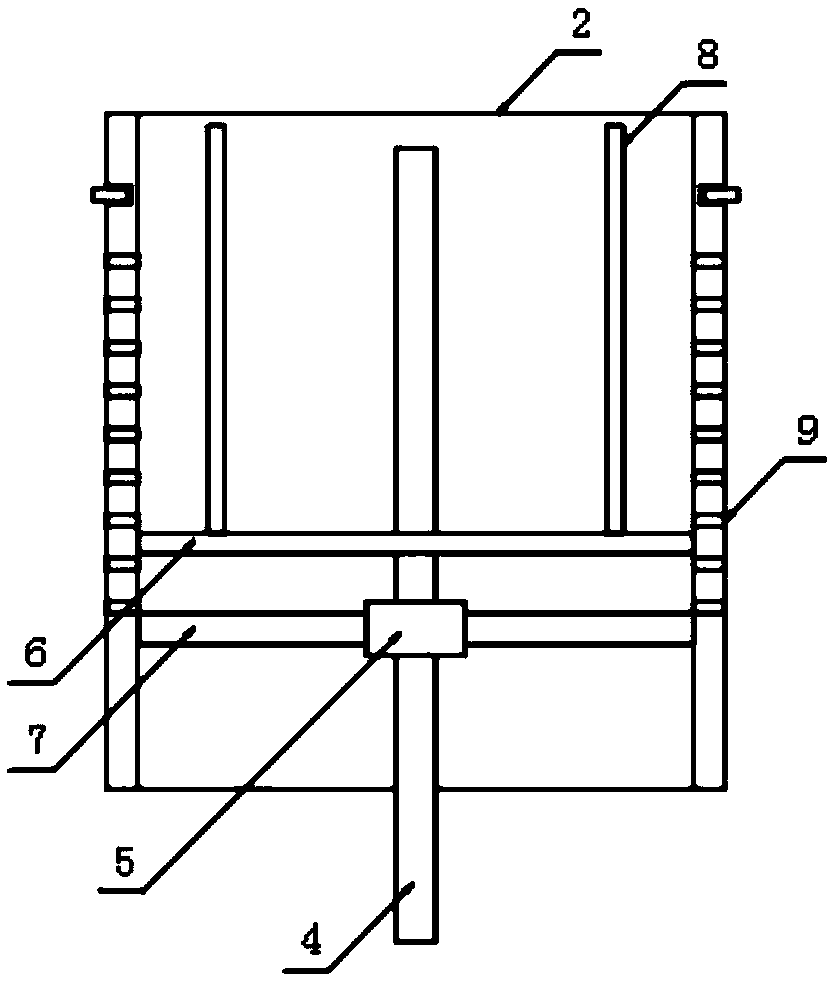

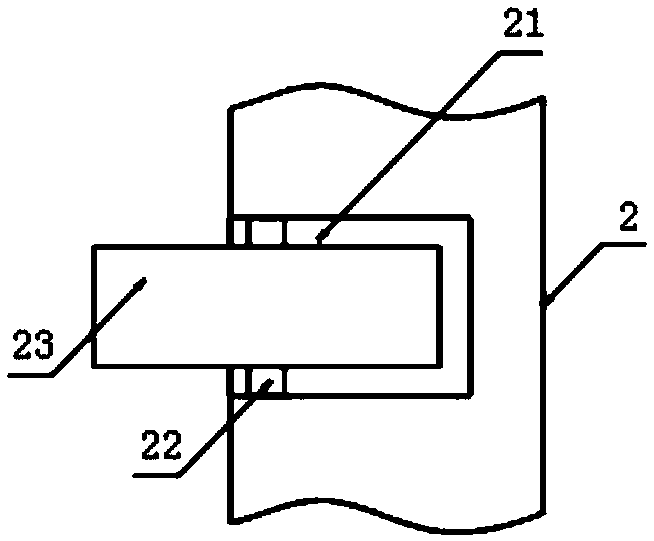

[0026] The present invention provides such Figure 1-3 A high-efficiency centrifugal dehydrator shown includes a shell 1, the shell 1 is provided with an inner tank 2 and a top cover 3, the inner tank 2 is provided with a screw 4, and the outer side of the screw 4 is A connecting block 5 and an extruding disc 6 are sleeved, the connecting block 5 is fixedly connected with the screw rod 4, the extruding disc 6 is threadedly connected with the screw mandrel 4, and a connecting rod 7 is provided on the outside of the connecting block 5, One end of the connecting rod 7 is fixedly connected to the connecting block 5 and the other end is fixedly connected to the liner 2, the top of the squeeze disc 6 is provided with a limit rod 8, the side wall of the liner 2 is provided with a filter hole 9, The bottom of the top cover 3 is provided with a limiting block 10 , and the bottom of the limiting block 10 is provided with a limiting slot 11 .

[0027] Further, in the above technical sol...

Embodiment 2

[0037] A high-efficiency centrifugal dehydration method, including the high-efficiency centrifugal dehydrator, also includes the following steps:

[0038] S1: Pour the kitchen waste into the garbage bag inside the liner 2;

[0039] S2: close the top cover 3;

[0040] S3: energize the motor 15. After the motor 15 is energized, the first gear 13 is driven to rotate through the transmission shaft 16 and the second gear 17. When the first gear 13 rotates, it drives the screw 4 on the top of the transmission block 12 to rotate, and the screw 4 is connected to the Block 5 and connecting rod 7 drive liner 2 to rotate;

[0041]S4: Centrifugal force is generated when the liner 2 rotates, which drives the kitchen waste inside the garbage bag to rotate together. At this time, due to the cooperation of the limit groove 11 and the limit rod 8, the extrusion plate 6 cannot rotate together with the screw rod 4;

[0042] S5: The extrusion disc 6 moves upward along the screw rod 4, at this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com