Drying volume reduction processing device

A treatment device and drying treatment technology, which is applied in the direction of drying gas arrangement, garbage drying, local agitation dryer, etc., can solve the problems of equipment cost increase, achieve the effect of improving drying efficiency, reducing pressure loss, and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

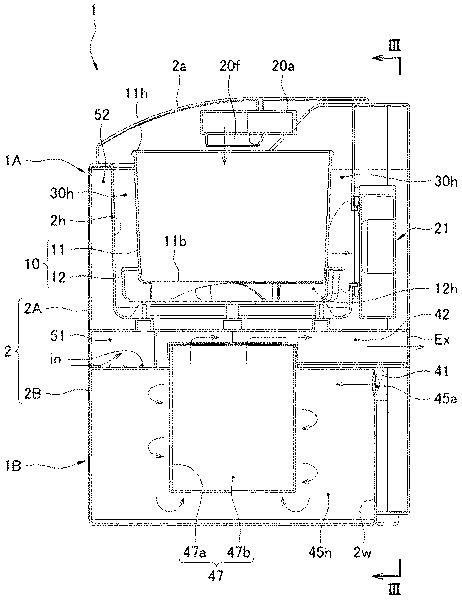

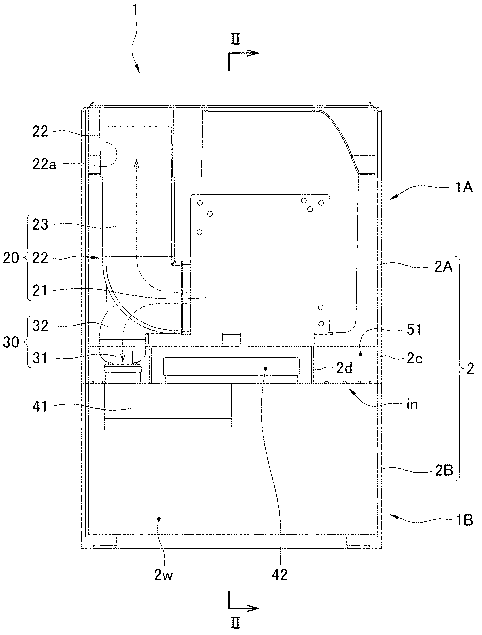

[0051] Next, explain the embodiments of the present invention based on the attachment.

[0052] The drying and reducing processing device of this embodiment is to handle the device of the processing objects containing. By allowing the processing objects to contact the heating air, the purpose of drying and reducing the volume of the processed object is achieved.

[0053] In addition, as a processing object for treatment objects, as long as it is a moisture, there is no special limitation, and the processing objects, such as the organic garbage excreted by the family, can also be processed, and there is no limit.

[0054] (Explanation of drying and reducing processing device 1)

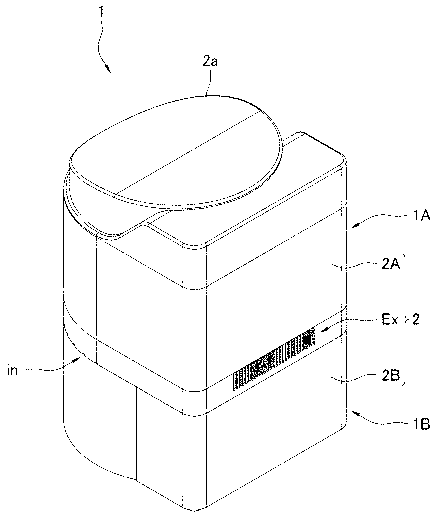

[0055] like Figure 1 to Figure 3 Show, the drying and reducing treatment device of this embodiment 1 has a processing container 10 and a box 2 in the drying and reducing treatment process after being placed in the processing object.EssenceIn the box 2, there is a heating air supply device that provides hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com