Reduced-pressure fermenting and drying apparatus

A fermentation drying and drying machine technology, which is applied in the direction of garbage drying, drying solid materials, local agitation dryers, etc., can solve the problems of low processing efficiency, easy deterioration, diffusion, etc., to improve drying efficiency, prevent the spread of odor, Effect of reducing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

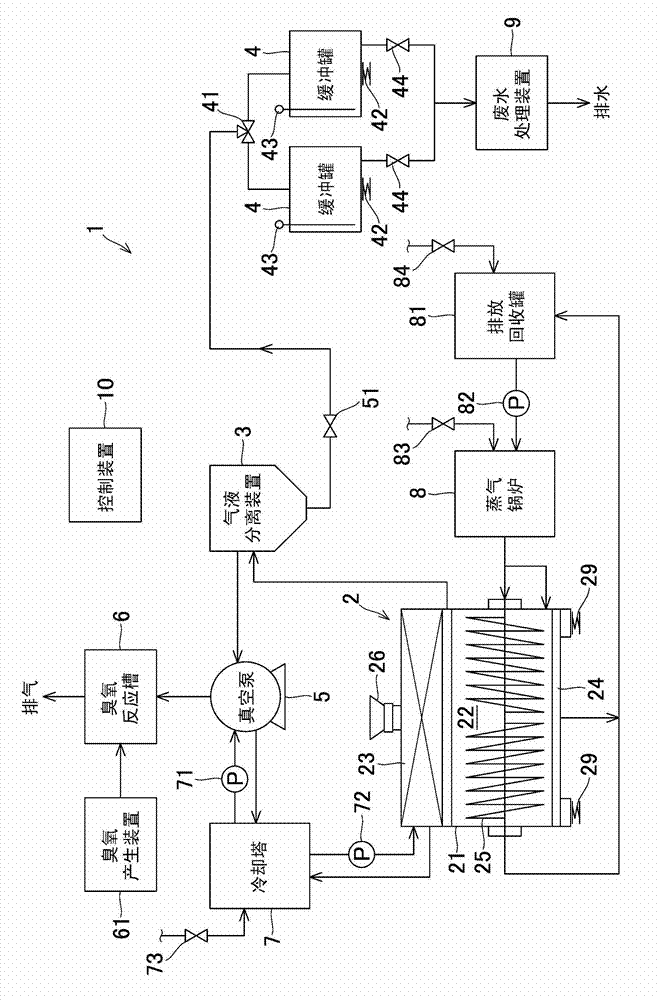

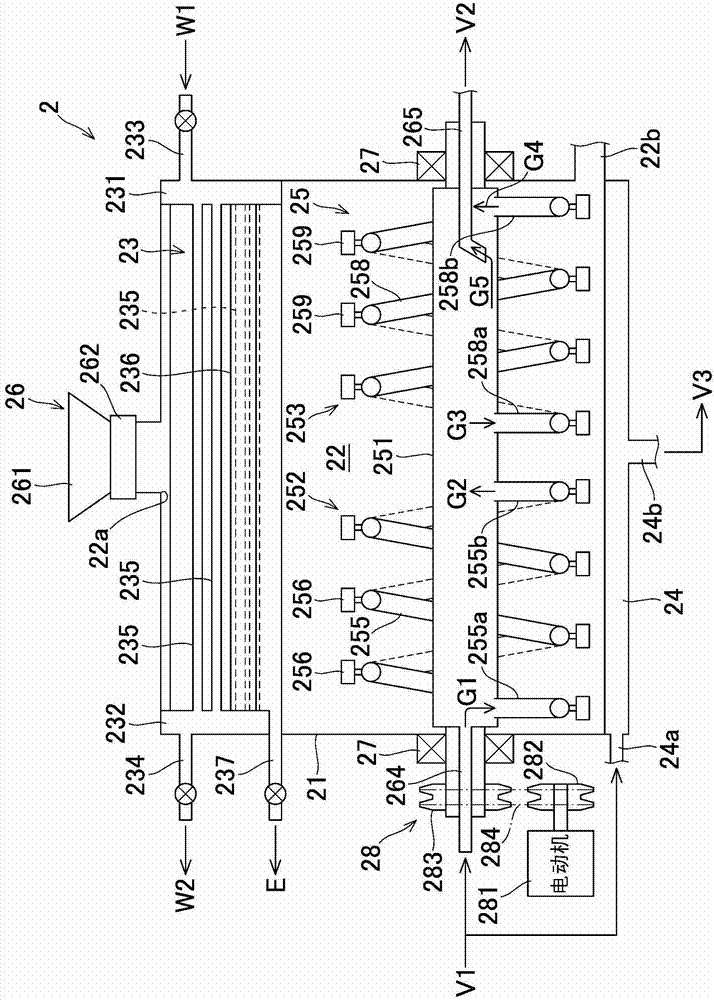

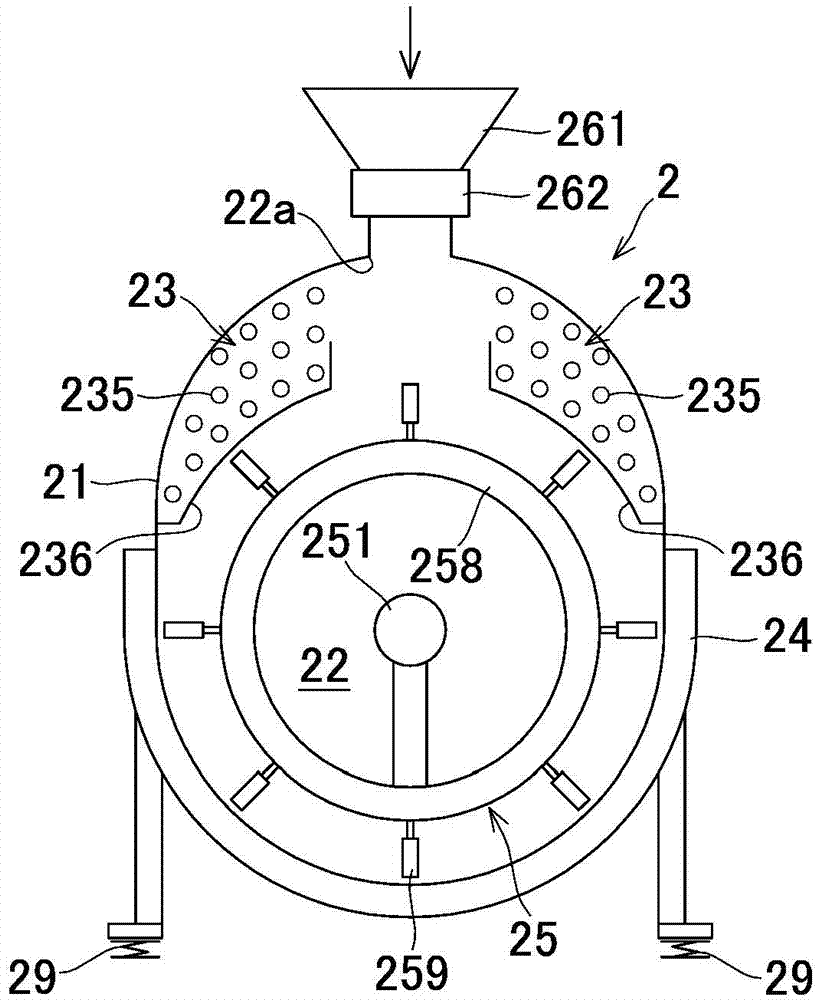

[0069] figure 1 It is a block diagram showing the overall structure of the vacuum fermentation drying apparatus which concerns on embodiment of this invention. This reduced-pressure fermentation drying apparatus 1 treats excess sludge with a water content exceeding 95% as a to-be-processed object. The decompression fermentation and drying device 1 generally includes: a drier 2 having a treatment chamber 22 for inputting the object to be treated inside; a gas-liquid separator 3 that guides condensed water from the drier 2; 2 buffer tanks 4,4 as the condensed water storage tank of water; The vacuum pump 5 as the suction pump that is connected with the downstream side of the gas-liquid separator 3; The ozone reaction tank 6 that is connected with the downstream side of the vacuum pump 5; A cooling tower 7 as a cooling machine for supplying cooling water as a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com