Novel ultrasonic cleaning machine

A technology of ultrasonic wave and cleaning machine, which is applied to dryers, cleaning methods and utensils, and cleaning methods using liquids, etc., which can solve the problems of incomplete cleaning and low cleaning power of wires, and achieve the effect of reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

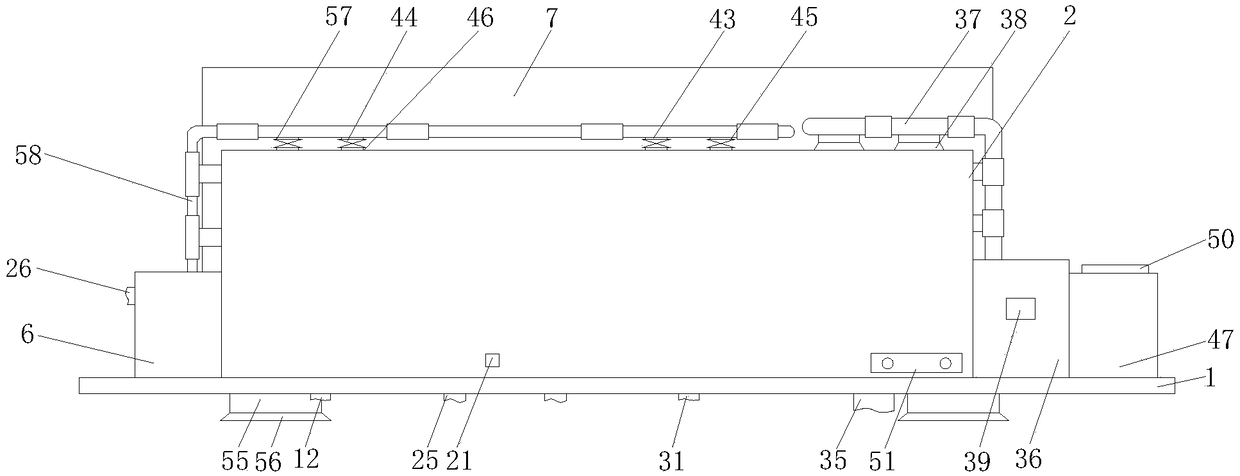

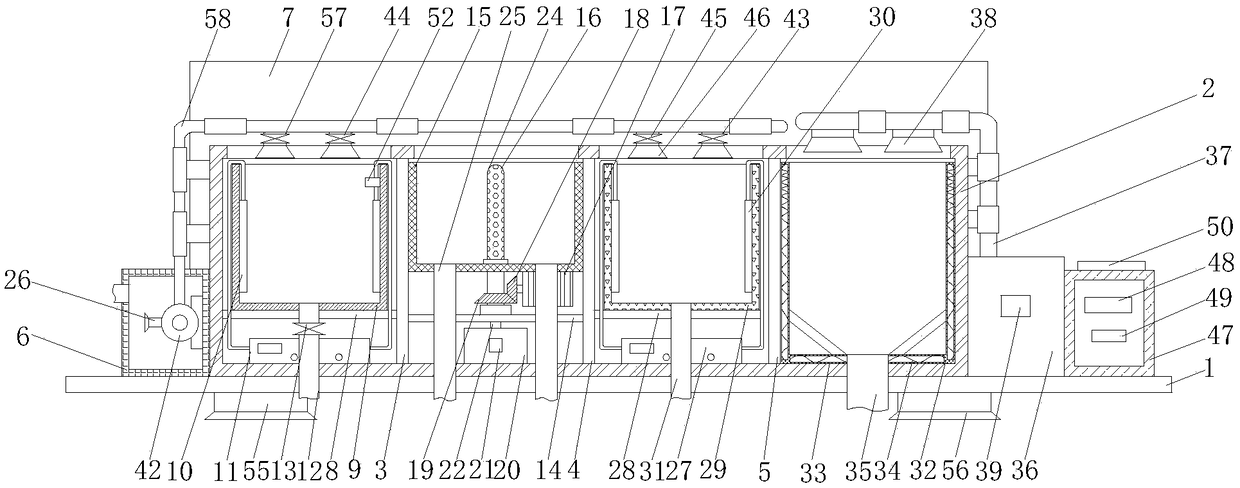

[0033] A new type of ultrasonic cleaning machine, including a bottom plate 1, support legs 55 are fixedly connected to both sides of the bottom of the bottom plate 1, rubber pads 56 are fixedly connected to the bottom of the support legs 55, and the cooperation between the support legs 55 and the rubber pads 56 can prevent the bottom plate from 1 The direct contact with the ground reduces friction and also plays a certain role in buffering and shock absorption, so that the ultrasonic cleaning machine can be used for a long time. The top of the bottom plate 1 and the side of the hot air blower 36 are fixedly connected with a rectangular box 47 , the back side of rectangular box 47 inwalls is fixedly connected with CPU 48, and the model of CPU 48 is ARM9, and the output end of CPU 48 is respectively connected with data comparator 49, water pump 42, the first electromagnetic leakage valve 44 and the 2nd. The input ends of the two electromagnetic leakage valves 45 are connected, an...

Embodiment 2

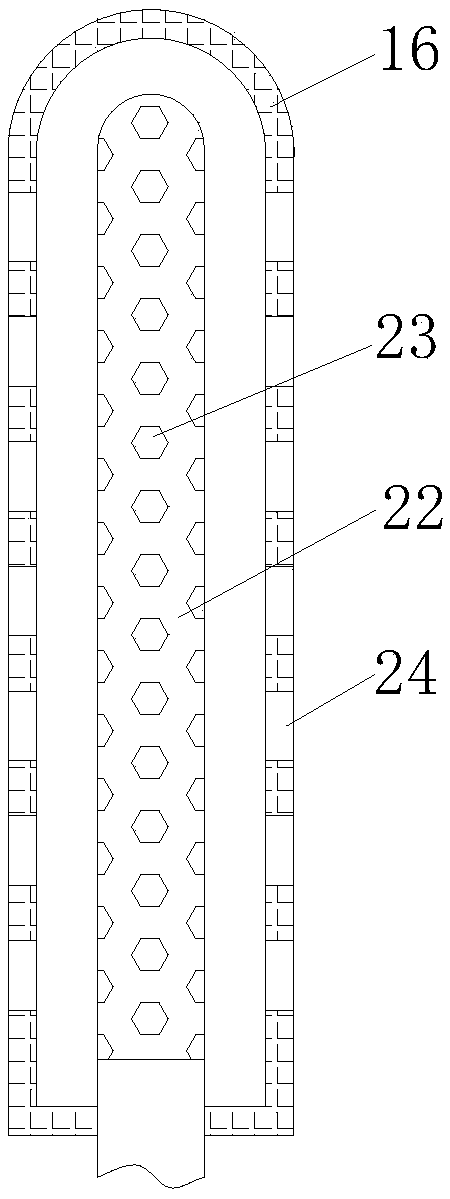

[0035] A new type of ultrasonic cleaning machine, comprising a bottom plate 1, the top of the bottom plate 1 is fixedly connected with an operation frame 2, and the top and bottom of the inner wall of the operation frame 2 are fixedly connected with a vertical plate 3 and a partition in sequence from left to right 4 and a support plate 5, the top of the bottom plate 1 is fixedly connected with a water tank 6 on one side of the operation frame 2, the top of the bottom plate 1 is fixedly connected with a support frame 7 at the back of the operation frame 2, and the operation frame 2 A horizontal plate 8 is fixedly connected between one side of the inner wall and one side of the vertical plate 3, and the top of the horizontal plate 8 is fixedly connected with a cleaning frame 9, and both sides of the inner wall of the cleaning frame 9 are fixedly connected with a first ultrasonic Vibration plate 10, the bottom of the inner wall of the operation frame 2 is fixedly connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com