Intelligent kitchen waste disposal machine and using method thereof

A kitchen waste and processing machine technology, which is applied in the fields of waste drying, grain processing, chemical instruments and methods, etc., can solve the problems of energy waste, low drying utilization rate, and long drying time, and achieves low energy consumption and heating. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] refer to Figure 1 to Figure 7 The embodiment of the smart kitchen waste disposer and the usage method of the present invention will be further described.

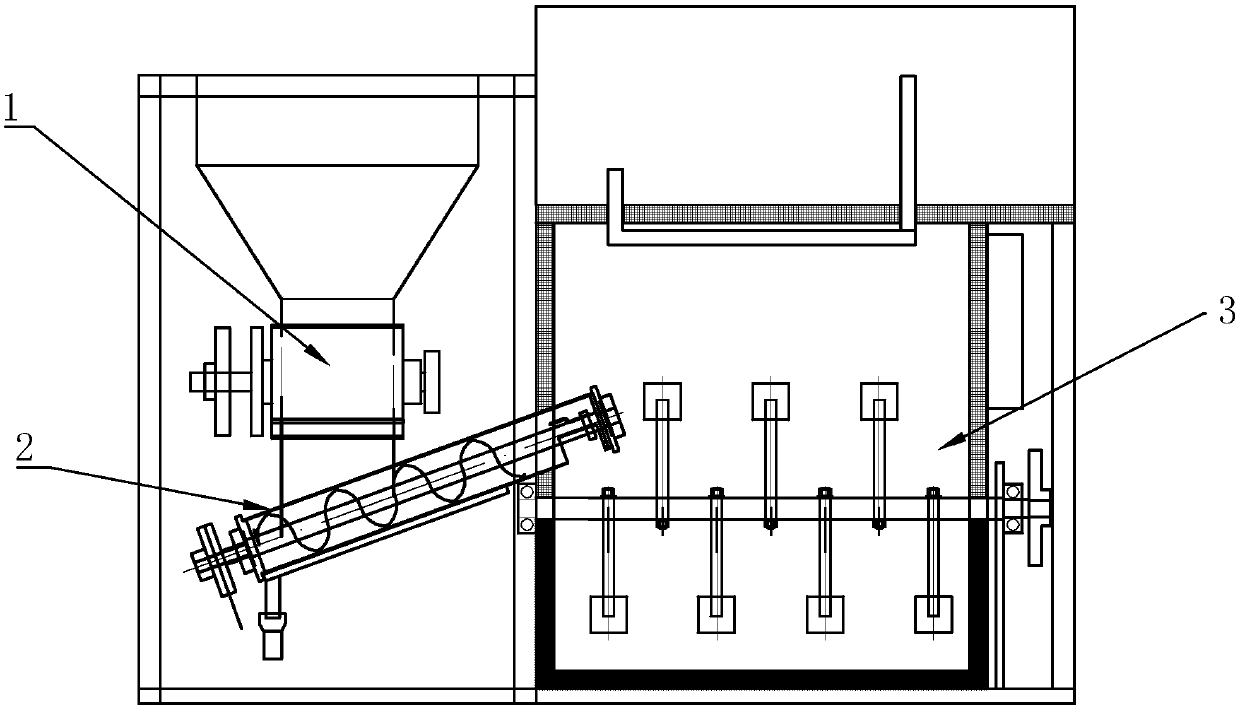

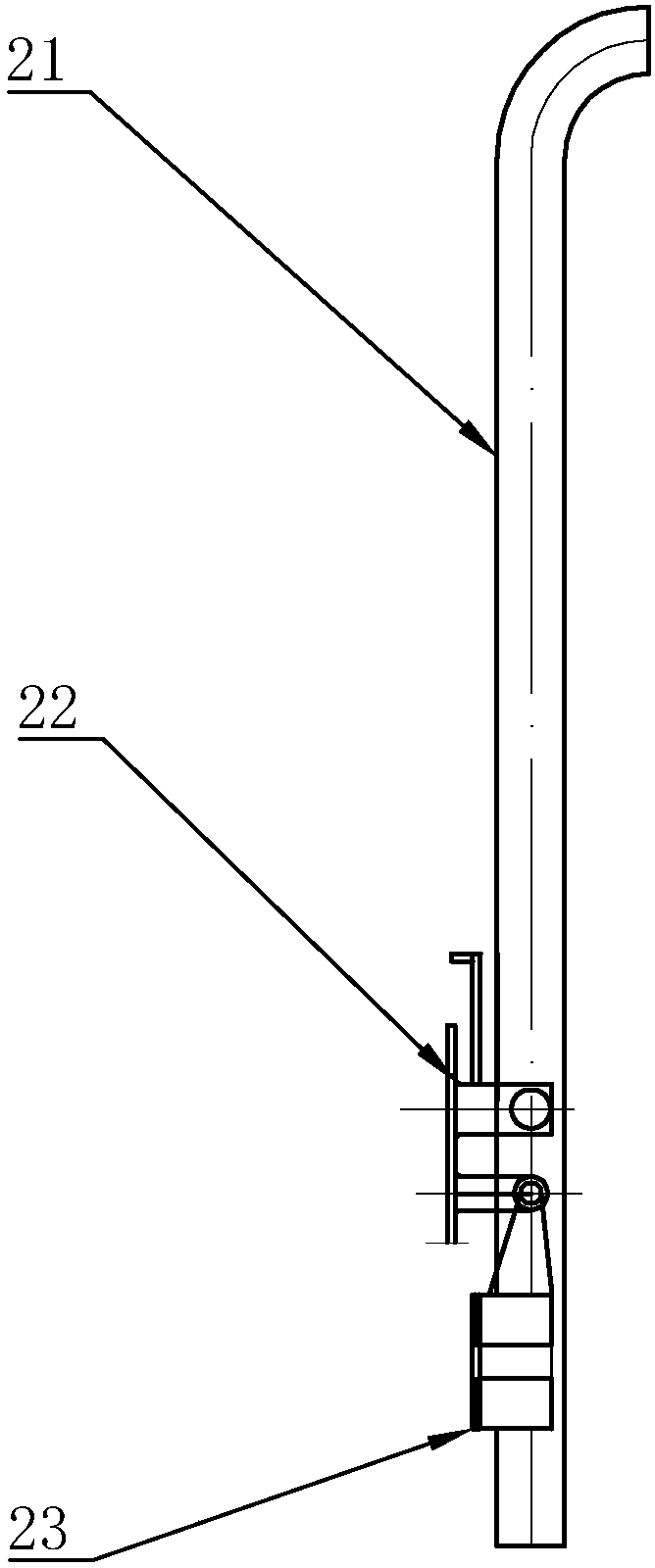

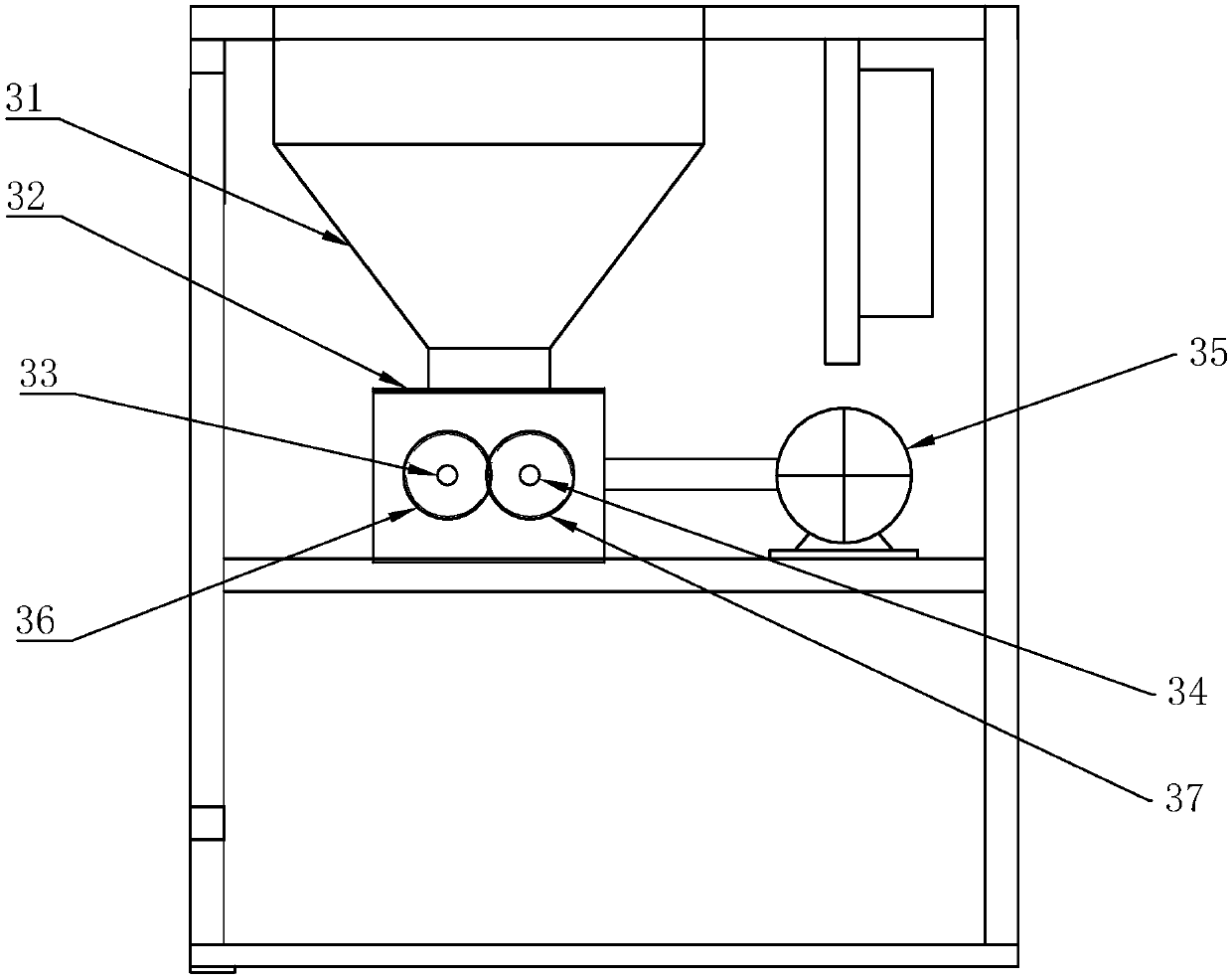

[0035] An intelligent kitchen waste disposer, see the specific structure figure 1 , including an automatic feeding device, a crushing device 1, a solid-liquid separation device 2 and an oil-water separation device, as well as a drying treatment device 3 using hot air circulation, such as figure 2 As shown, the automatic feeding device includes a slideway 21, a lift 22 and a trash can 23, and the standard trash can 23 of 120L / 240L is applicable. The slideway 21 is vertically installed on the outer side wall of the crushing box 32 and extends To the top of the feed hopper 31, the slideway 21 is L-shaped, and the elevator 22 is slid and installed in the slideway 21 by rollers, and the elevator 22 works by sliding the rollers in the vertical slideway 21. There is a hook, the garbage can 23 is hung on the hook, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com