In-barrel vacuum microwave drying system and method for radioactive wet wastes

A vacuum microwave drying and drying system technology, used in radioactive purification, garbage drying, sludge drying, etc., can solve the problems of increased disposal costs, large capacity expansion ratio, and non-compliance with the principle of minimizing radioactive waste. , The heating temperature is uniform, which is conducive to the effect of water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

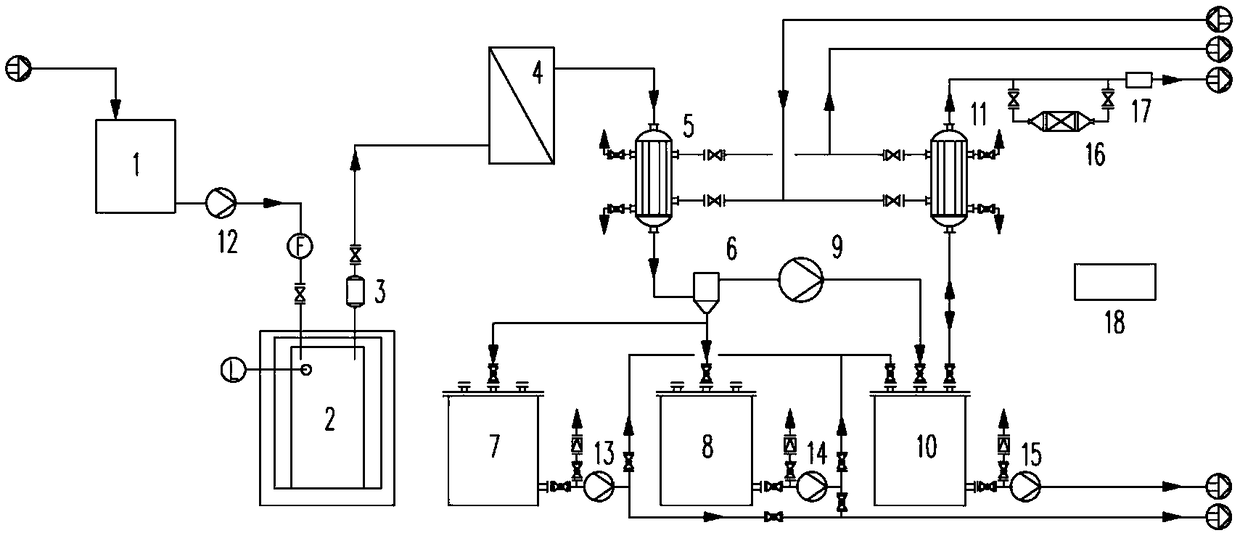

[0032] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] The composition of the vacuum microwave drying system in the exemplary radioactive wet waste bucket of the present invention is as follows: figure 1 As shown, it includes a pretreatment part (also includes a pretreatment device 1, a first delivery pump 12), a microwave vacuum drying part in a barrel (also includes a drying barrel 2 placed in a drying station), an exhaust gas purification and condensation treatment part (also includes Demister 3, filter 4, first condenser 5, steam-water separator 6, first condensate storage tank 7, second condensate storage tank 8, vacuum pump 9, non-condensable gas storage tank 10, second condenser 11. The second delivery pump 13, the third delivery pump 14, the fourth delivery pump 15, the adsorption filter 16), the monitoring analysis part (also includes the tail gas continuous monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com