Bacterial cellulose edible packaging product and production method thereof

A technology of bacterial cellulose and bacterial cellulose film, which is applied in the field of biotechnology and food packaging materials, can solve the problem of high cost, achieve the effect of reducing consumption and alleviating pollution pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

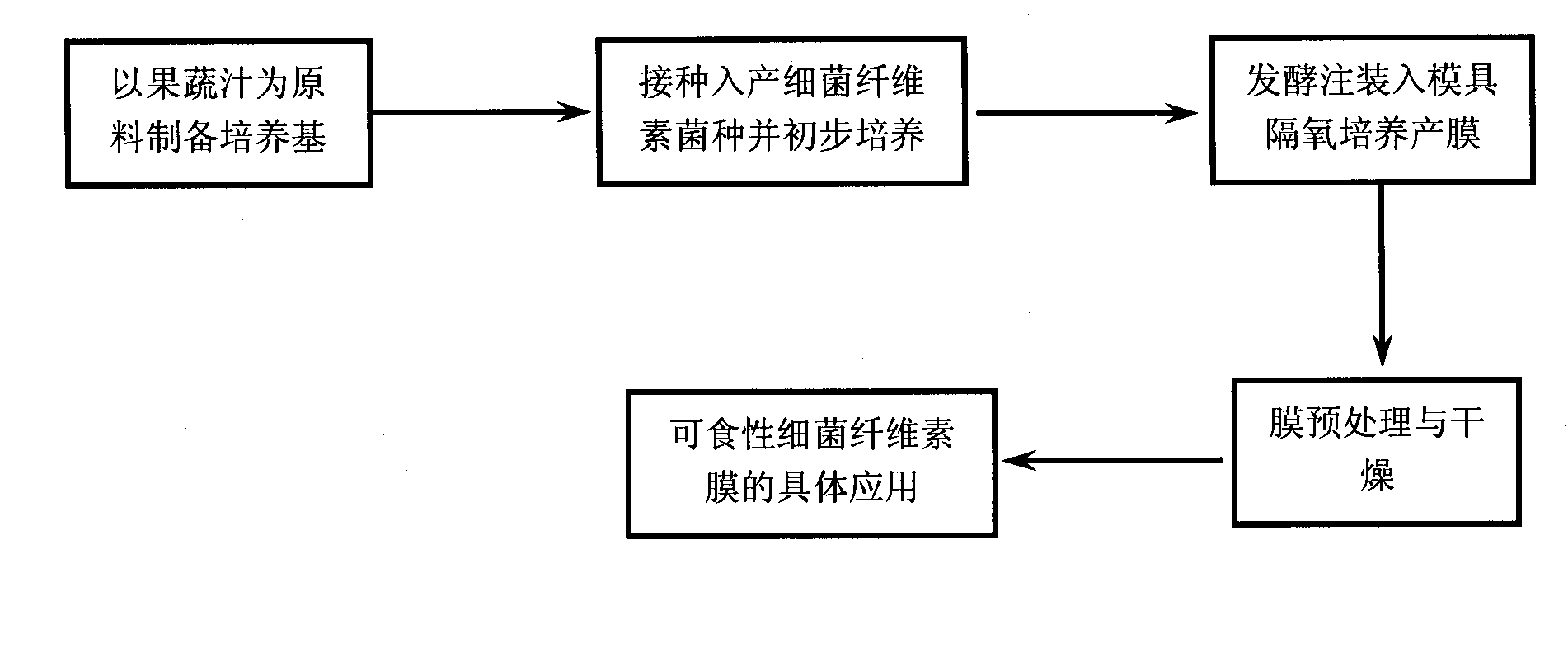

Method used

Image

Examples

Embodiment example 1

[0020] Take 10L of coconut water, add MgSO 4 0.02%, KH 2 PO 4 0.02%, NaCl 0.5%, filter out the insoluble matter, adjust the pH to 7.0, put it into a 15L fermenter, heat it with steam, sterilize at 110°C for 30min, and cool it to 29°C with cooling water. Inoculate 1 L of Acetobacter xylinum species prepared by shaking flasks into 10 L medium by flame method, with an inoculum size of 10%. The stirring speed is 150 rpm, the ventilation ratio is 1:3, the temperature is controlled at 29° C., and fermentation is carried out for 5 hours. Then put the fermented liquid into sterilized glass molds with specifications of 20cm×7cm×8cm (length×width×height). Static culture for 6 days. Collect the grown bacterial cellulose wet film, soak it in 1% NaOH solution for 20 minutes in a sterile room, then soak it in 2% hydrogen peroxide for 30 minutes to decolorize it, then rinse it with sterile water until it is neutral, and dry it in an oven at 105°C. Make a bacterial cellulose dry film wit...

Embodiment example 2

[0022] Take chayote juice 10L, add MgSO 4 0.02%, KH 2 PO 4 0.02%, NaCl 0.5%, heat and boil for 5 minutes to destroy chlorophyll, then filter to remove insoluble matter, adjust pH to 7.2, put into a 15L fermenter, heat with steam, sterilize at 110°C for 30min, and cool to 29°C with cooling water. Inoculate 1 L of Acetobacter xylinum species prepared by shaking flasks into 10 L medium by flame method, with an inoculum size of 10%. The stirring speed is 150 rpm, the ventilation ratio is 1:3, the temperature is controlled at 29° C., and fermentation is carried out for 5 hours. Then put the fermented liquid into sterilized plastic molds with specifications of 20cm×7cm×8cm (length×width×height). Static culture for 6 days. Collect the grown bacterial cellulose wet film, soak it in 0.8% NaOH solution for 30 minutes in a sterile room, then soak it in 1.5% hydrogen peroxide for 40 minutes to decolorize, then wash it with sterile water until neutral, and dry it in an oven at 105 ° C....

Embodiment example 3

[0024] Take chayote juice 80L, add MgSO 4 0.02%, KH 2 PO 40.02%, NaCl 0.5%, heating and boiling for 5 minutes to destroy chlorophyll, then filter to remove insoluble matter, and adjust pH to 7.2. Take 10L, put it into a 15L seed tank, heat it with steam, sterilize at 110°C for 30min, and cool it down to 28°C with cooling water. Inoculate 1 L of Acetobacter xylinum species prepared by shaking flasks into 10 L medium by flame method, with an inoculum size of 10%. The stirring speed is 150 rpm, the ventilation ratio is 1:3, the temperature is controlled at 28° C., and fermentation is carried out for 8 hours. The remaining 70L was put into a 100L fermenter, heated by steam, sterilized at 110°C for 30min, and cooled to 28°C with cooling water. The seeds were sent by the pressure difference method, the stirring speed was 150 rpm, the ventilation ratio was 1:2, the temperature was controlled at 28° C., and fermentation was carried out for 4 hours. Then put the fermented liquid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com