Method for treating fermentation filter residue and livestock and poultry manure mixture on large scale through fly maggots

A technology for fermenting filter residue and livestock and poultry manure, which is applied in the field of fly maggot breeding, can solve the problems of high viscosity of fermentation filter residue, long time, and difficult conversion and utilization of fly maggot, so as to improve economic and social benefits, reduce the pressure of environmental pollution, Realize the effect of industrialized processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the present invention is described in detail with reference to the accompanying drawings.

[0028] A kind of method that utilizes fly maggot large-scale treatment fermentation filter residue and livestock and poultry manure mixture provided by the invention, the steps are as follows:

[0029] The first step is to fully stir the fresh fermented filter residue and livestock and poultry manure to control the appropriate pH value. The pH of livestock and poultry manure is often neutral or weakly alkaline, and the pH of fermentation filter residue is often lower than 4.5, which is difficult to be directly used for the transformation and utilization of fly maggots. After stirring and mixing the fermentation filter residue with a certain proportion of livestock and poultry manure, the pH It is just suitable for fly maggot breeding, and also increases the protein and other nutrient content of livestock and poultry manure, which is very suitable for fly maggo...

Embodiment 2

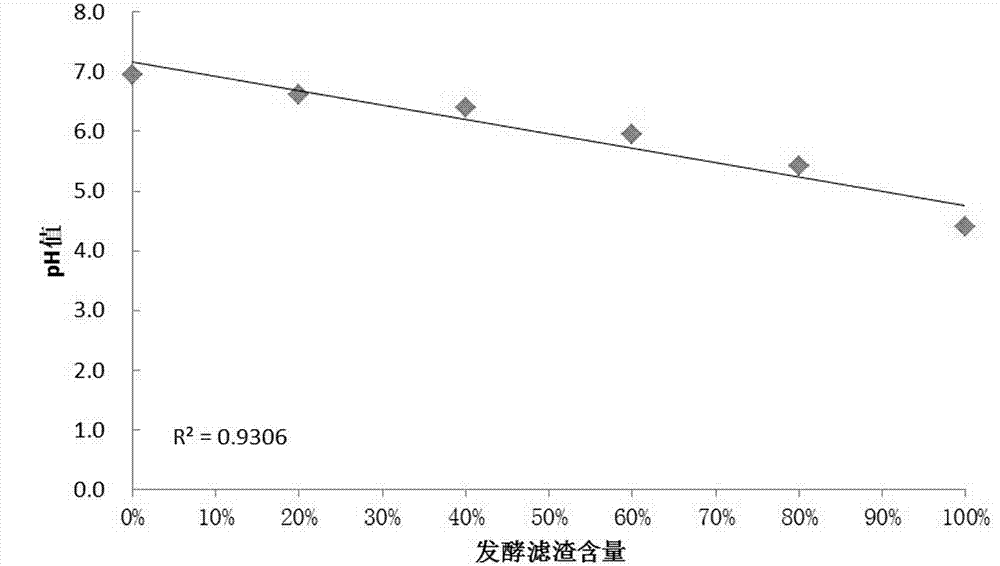

[0044] combined with figure 1 , In this implementation, the effect of the content of fermentation residue on the pH of the culture material is described in detail.

[0045]The measured pH of fresh pig manure and fermentation filter residue were 6.95 and 4.395, respectively. With the increase of the amount of fermentation residue added, the pH of the compost decreased gradually, but when the content of the fermentation residue was lower than 60%, the initial pH of the compost was >6.0, which was still suitable for the growth of fly maggots. When the content of the fermentation residue exceeded 60%, %, the pH of the compost will be lower than 6.0, which is not suitable for fly maggot breeding. Therefore, it is appropriate to add <60% of the fermentation filter residue in the initial culture material.

Embodiment 3

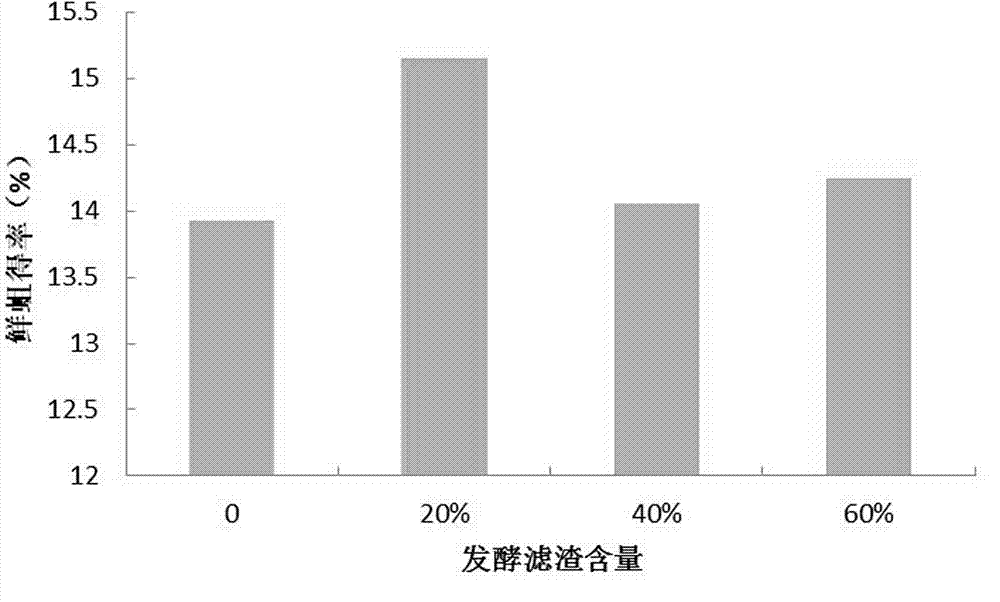

[0047] combined with figure 2 , describe in detail the influence of fermentation filter residue content on fly maggot yield in this implementation

[0048] The higher the yield of fresh maggots, the more fully the treatment of fermentation residues will be. By measuring the yield of fresh maggots in compost with different contents of fermentation filter residues, it can be known that fermentation filter residues can promote the yield of fresh maggots, compared with pure pig manure by 20% and 40%. , 60% fermented filter residue content compost increased than pure pig manure, respectively, 8.88%, 0.90% and 2.33%, of which 20% added the highest rate of fresh maggots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com