Patents

Literature

63results about How to "Catalytic conditions are mild" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting purple potato pigment by using ultrasonic wave and compound enzyme

InactiveCN101530191AIncreased diffusion rateImprove extraction efficiencyFood preparationSolventMacroporous resin

The invention relates to a method for extracting purple potato pigment by using ultrasonic wave and compound enzyme, which includes steps of (1) preprocessing raw material; (2) extracting the purple potato pigment by using ultrasonic wave and compound enzyme; and (3) refining extract by using macroporous resin. By using ultrasonic wave extraction technology, the present invention accelerates diffusion speed of educt from the raw material to solution, and has characteristics high extraction efficiency, no need of high temperature low energy consumption, and greatly shortened extraction time, the enzyme has characteristics of high catalytic efficiency, strong effect specificity and mild catalytic condition, and can increase productivity, lower energy consumption, reduce pollution, simplify process when being used in industry. By combining the ultrasonic wave extraction technology and the biological enzyme technology, the invention has advantages of short extraction time, high production yield, simple process, easy control of operation, convenience for large scale industrialization production and obvious economic benefit.

Owner:HEFEI UNIV OF TECH

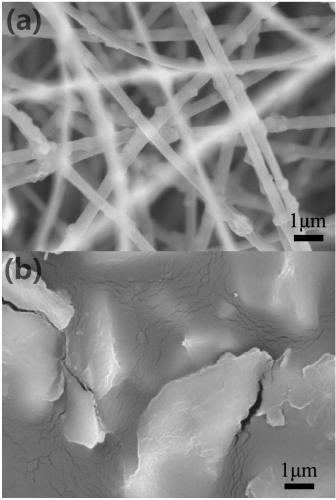

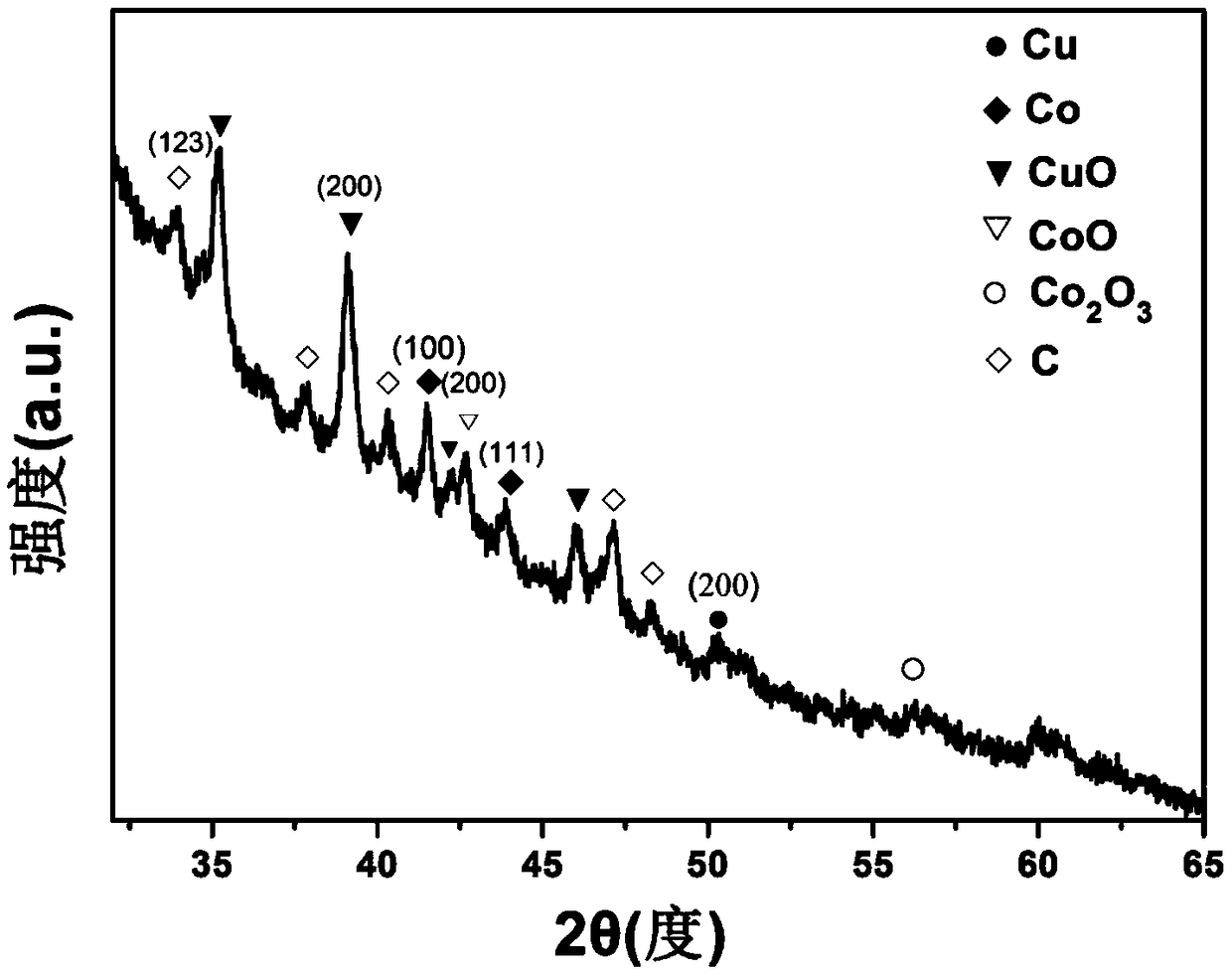

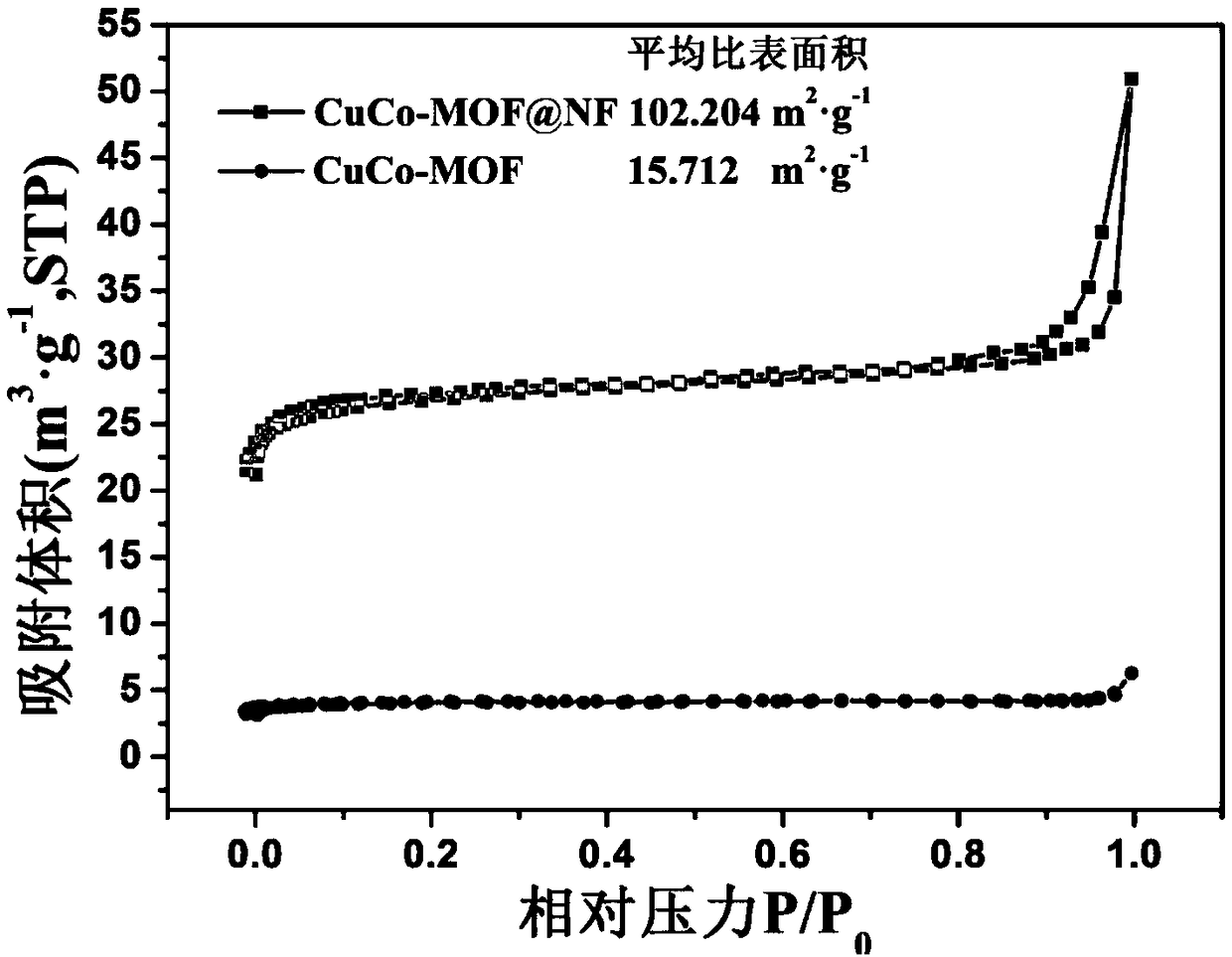

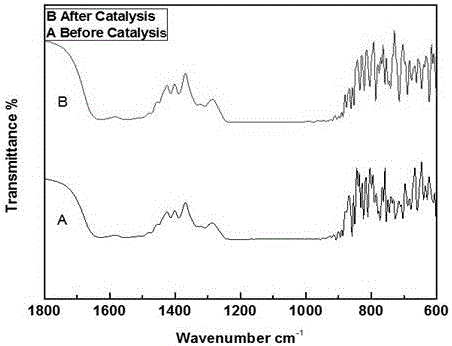

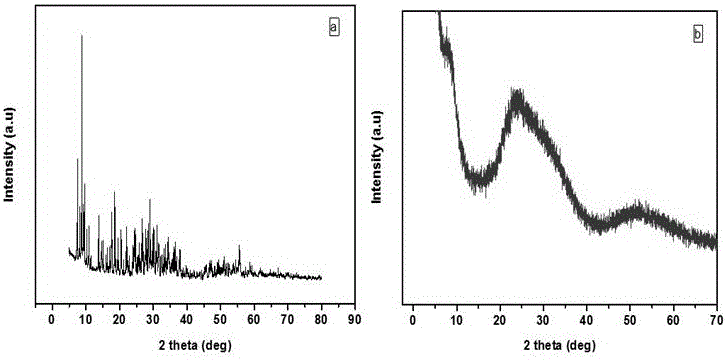

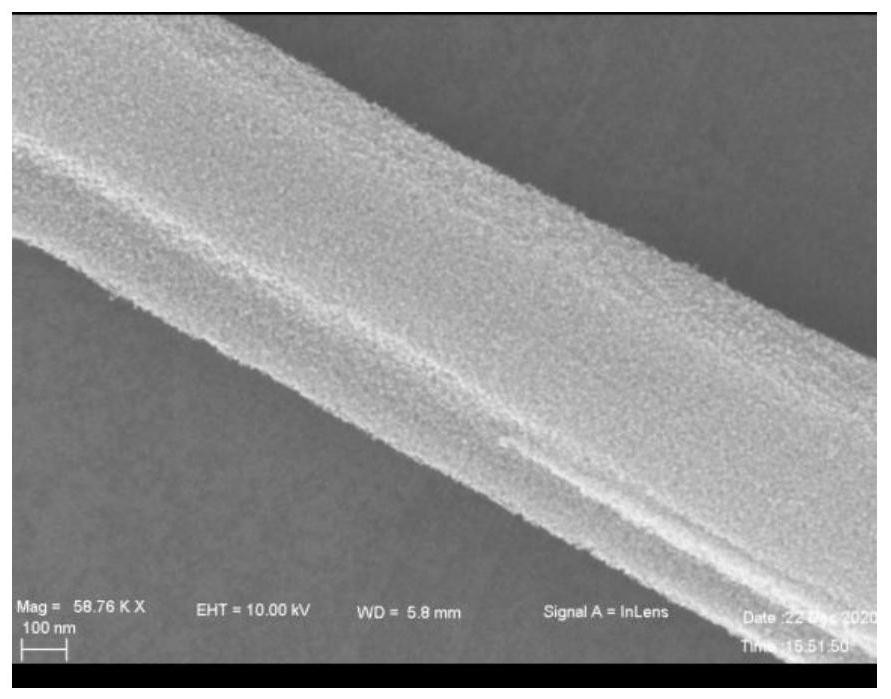

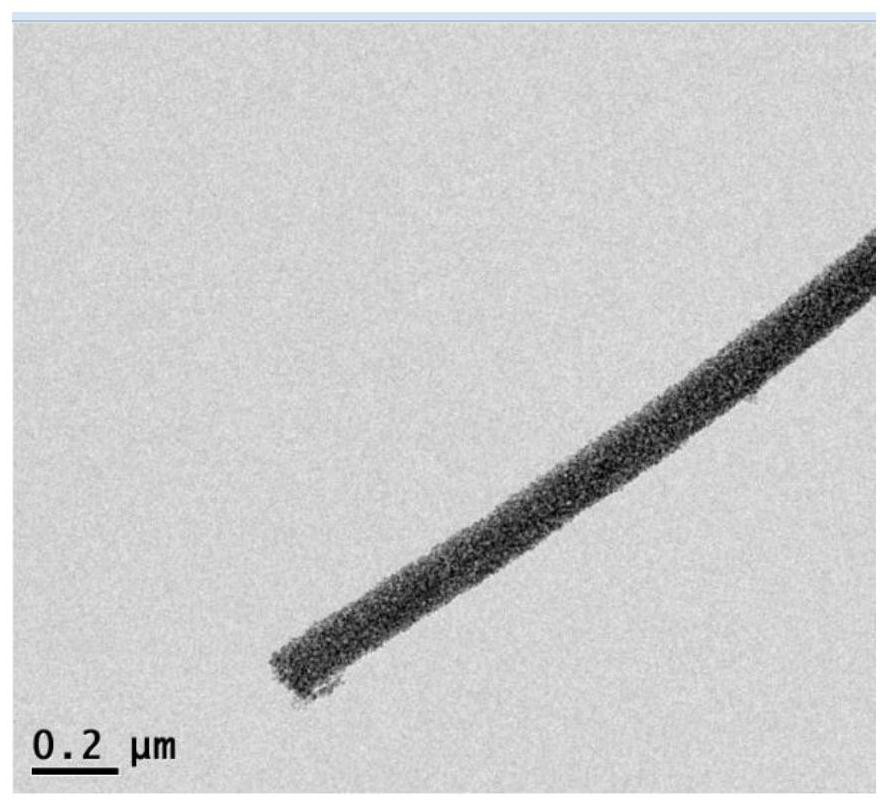

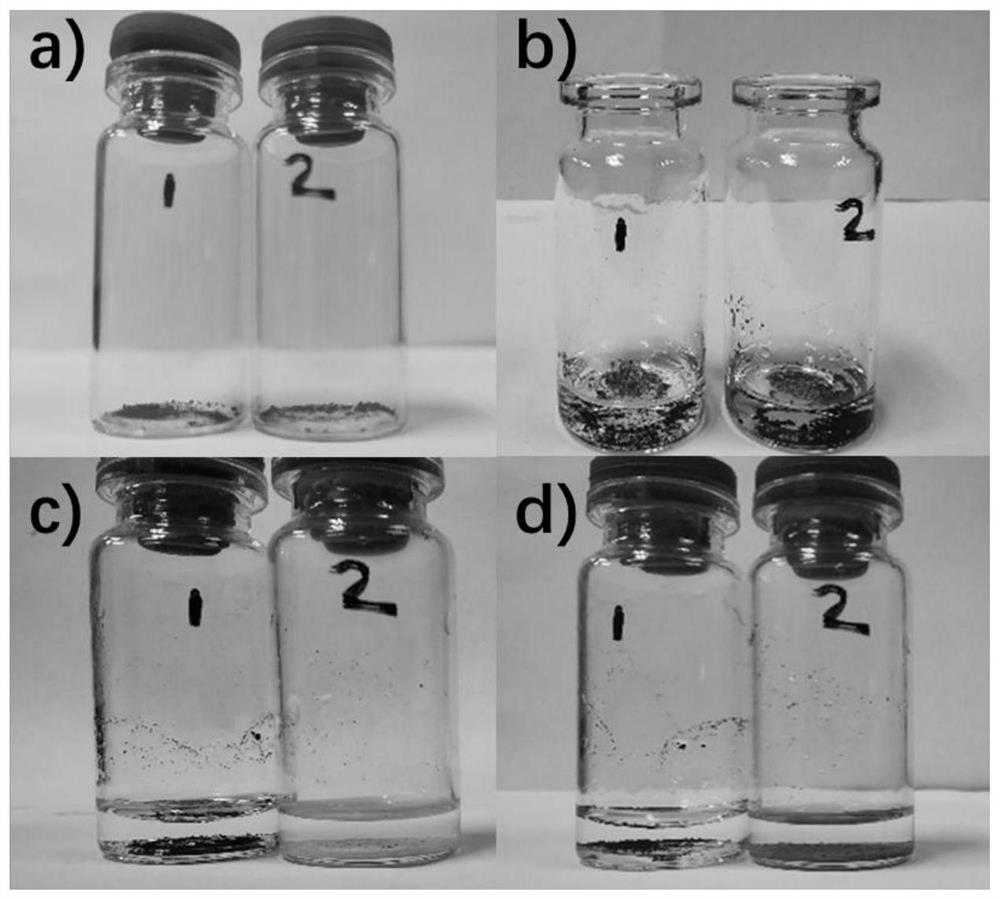

Copper-cobalt double-metal organic framework/nano-fiber composite material, preparation method thereof and application of composite material

InactiveCN109126885AImprove catalytic performanceImprove catalytic stabilityOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsFiberMetal-organic framework

The invention discloses a copper-cobalt double-metal organic framework / nano-fiber composite material (CuCo-MOF@NF). A preparation method of the composite material includes the steps: firstly, preparing a copper-cobalt double-metal organic framework by a solvothermal method; secondly, mixing the copper-cobalt double-metal organic framework and a high-molecular polymer to prepare the copper-cobalt double-metal organic framework / nano-fiber composite material by an electrostatic spinning method. The composite material has excellent catalytic effects on azo-dyes such as rhodamine B (cationic dyes)and acid red 1 (anionic dyes) at normal pressure and temperature. The preparation method of the composite material is simple, a catalyst is convenient to operate and recycle, high in catalytic efficiency, good in stability and less in dosage, mass production of the composite material is easily achieved, and the composite material has an excellent application prospect in respects of catalytic degradation of azo-dyes in industrial wastewater and control of other pollutants.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for photocatalytic synthesis of sulfur sulfone compounds

ActiveCN109705002ASubstrate raw materials are easy to obtainLow costOrganic chemistryOrganic compound preparationHigh volume manufacturingSulfur

The invention discloses a method for photocatalytic synthesis of sulfur sulfone compounds, and belongs to the technical field of catalysis. The invention provides a novel green environmentally-friendly method to efficiently synthesize the sulfur sulfone derivatives, and one thioether compound and an oxidizing agent are subjected to direct oxidization to form one corresponding sulfur sulfone compound under illumination by utilizing cercosporin as a catalyst. The method provided by the invention adopts the cercosporin as the catalyst, the catalytic conditions are milder, the reaction can be performed at room temperature under visible light irradiation, the catalyst has high catalytic activity and can be used for high-selectivity catalytic synthesis of the sulfur sulfone compounds, and the micro catalyst can make a yield higher, wherein the yield can reach 90% or more; and the photocatalyst and substrate raw materials used in the method are simple and easy to obtain, have low costs and can be produced on a large scale, and the method has very good application prospects.

Owner:JIANGNAN UNIV

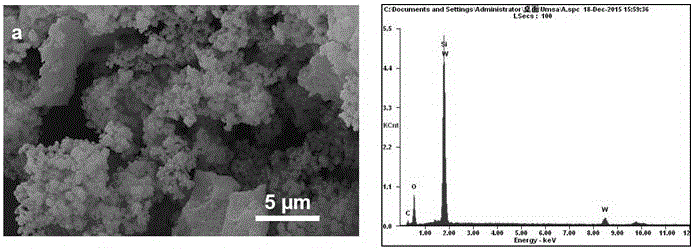

Supported tungsten-gallium polyoxometallate catalyst and preparation method and application thereof

ActiveCN105689002ACatalytic conditions are mildImprove conversion rateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystTriethoxysilane

The invention discloses a supported tungsten-gallium polyoxometallate catalyst and a preparation method and application thereof.Keggin type tungsten-gallium polyoxometallate is fixed to the surface of porous silicon dioxide successfully by grafting APTES on the surface of the porous silicon dioxide with the nanometer scale pore diameter, and the novel supported tungsten-gallium polyoxometallate catalyst is obtained.According to the catalyst, molecular oxygen can be used as an oxidizing agent, and the high conversion rate and good selectivity can be obtained when the catalyst is used for epoxidation reaction of cyclohexene on the solvent-free condition.

Owner:ZHEJIANG UNIV

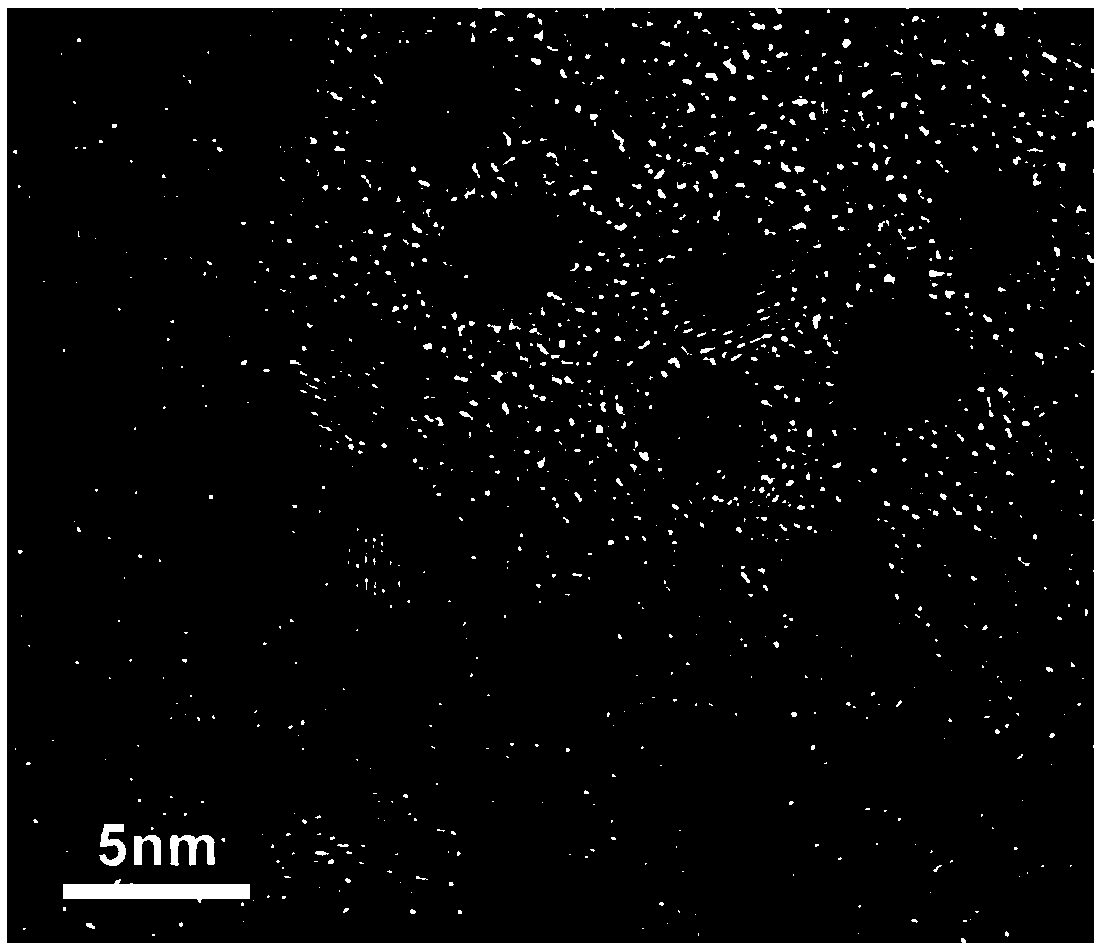

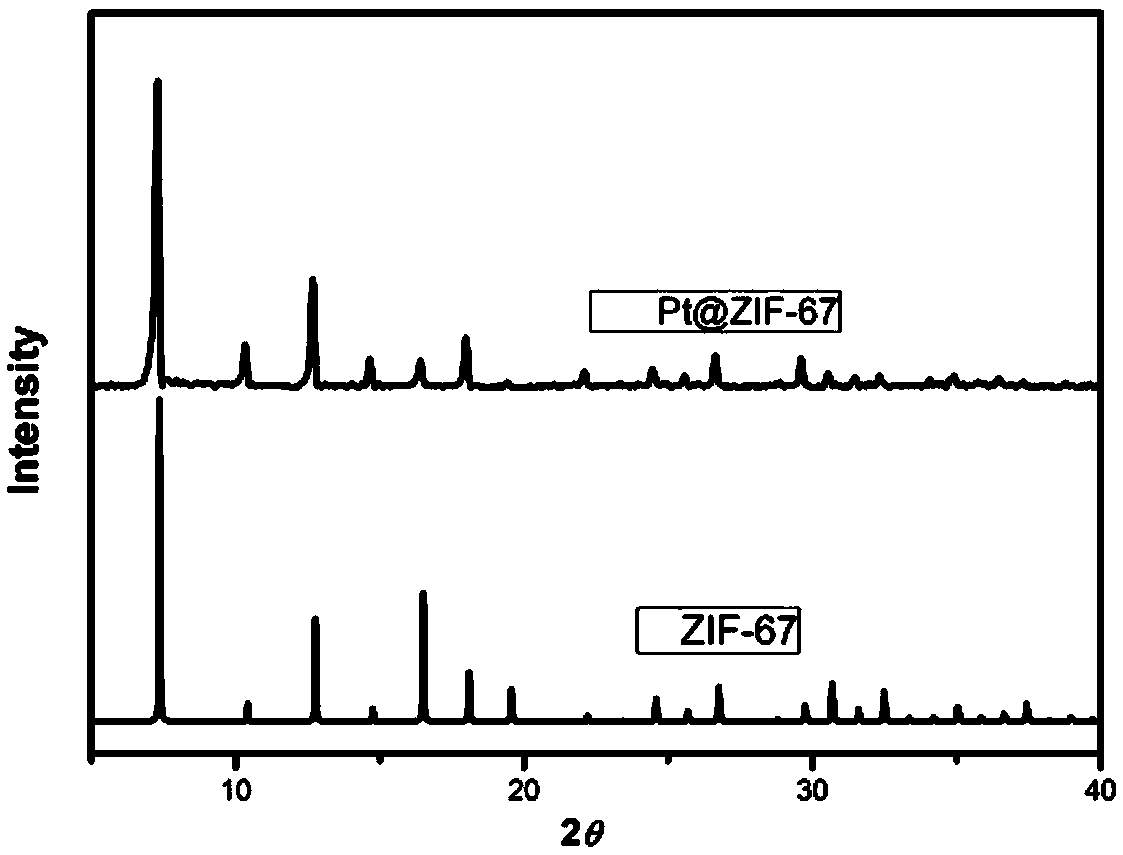

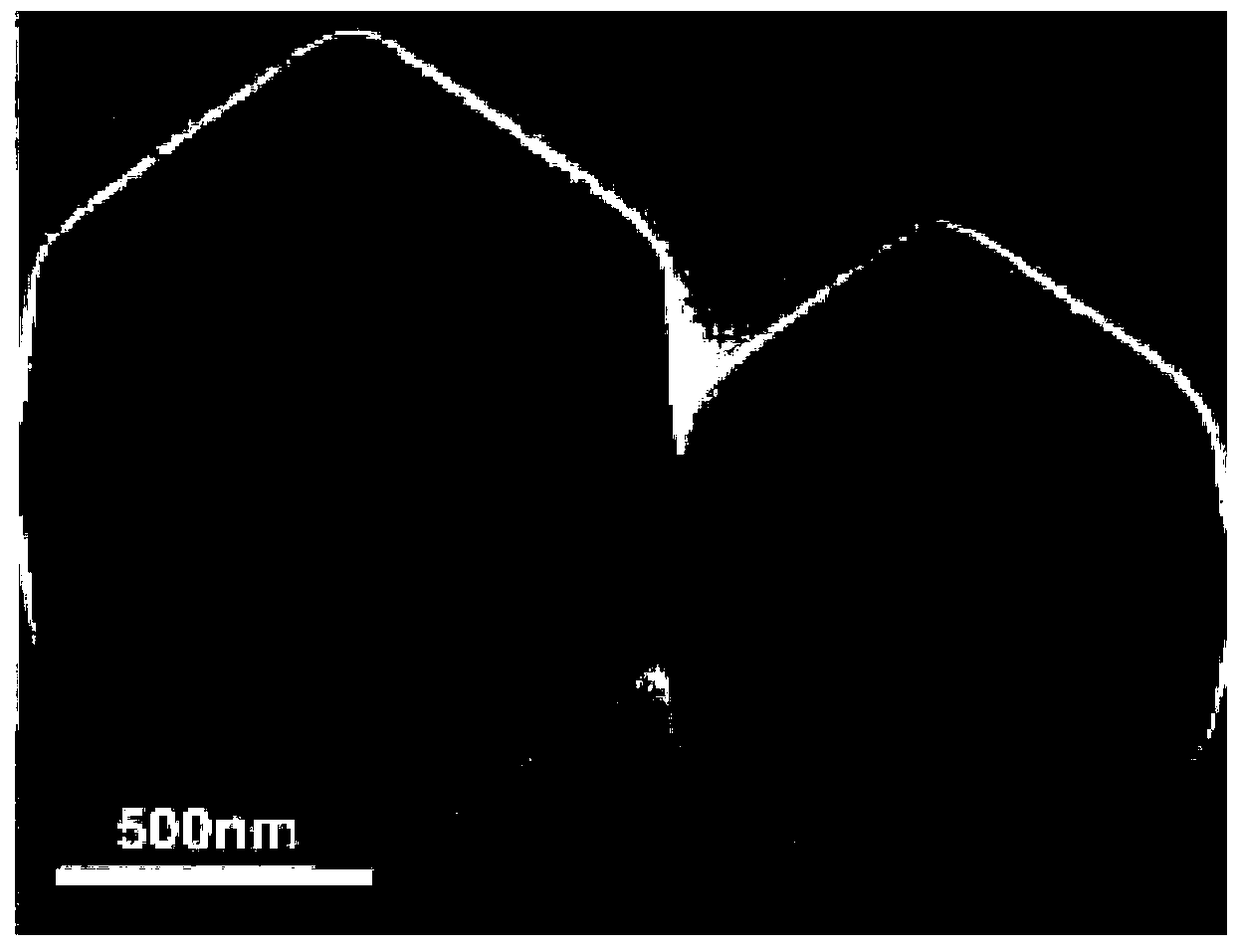

Method for improving selectivity of citronellol synthesized through citronellal hydrogenation

ActiveCN108610236ACatalytic conditions are mildImprove efficiency and productivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsNanometreChemistry

The invention discloses a method for improving selectivity of citronellol synthesized through citronellal hydrogenation. The method comprises the following steps: taking metal nano-particle @MOFs as acatalyst, performing activating treatment, and catalyzing selective hydrogenation of citronellal to produce citronellol accompanying with stirring and heating under the conditions of a hydrogen atmosphere and a pressure of 0.1-1MPa. Compared with the traditional catalytic reaction process, the method disclosed by the invention is mild in catalytic conditions and high in efficiency and yield, andhas high selectivity of the principal product citronellol. Moreover, according to the method, the nanoscale metal nano-particles are coated in the MOFs, and due to a protective effect of the MOFs structure, the metal nano-particles do not agglomerate and re-grow in the reaction process, so that the continuous high efficiency and stability of the catalyst are ensured.

Owner:NANJING UNIV OF TECH

Preparation method of lithium-loaded silica gel catalyst

InactiveCN104190396AHigh catalytic efficiencyCatalytic conditions are mildMetal/metal-oxides/metal-hydroxide catalystsLithium chlorideSilicic acid

The invention discloses a preparation method of a lithium-loaded silica gel catalyst. The lithium-loaded silica gel catalyst is prepared from silicic acid hydrosol and lithium chloride powder in a gelling manner. According to the preparation method of the lithium-loaded silica gel catalyst, lithium with catalytic action is dispersed and fixed to a silica gel carrier. Compared with the prior art, the method disclosed by the invention has the advantages that the catalytic efficiency is higher, the required catalytic conditions are milder, and the industrial production is facilitated.

Owner:PURESCI ENVIRONMENTAL TECH CO LTD

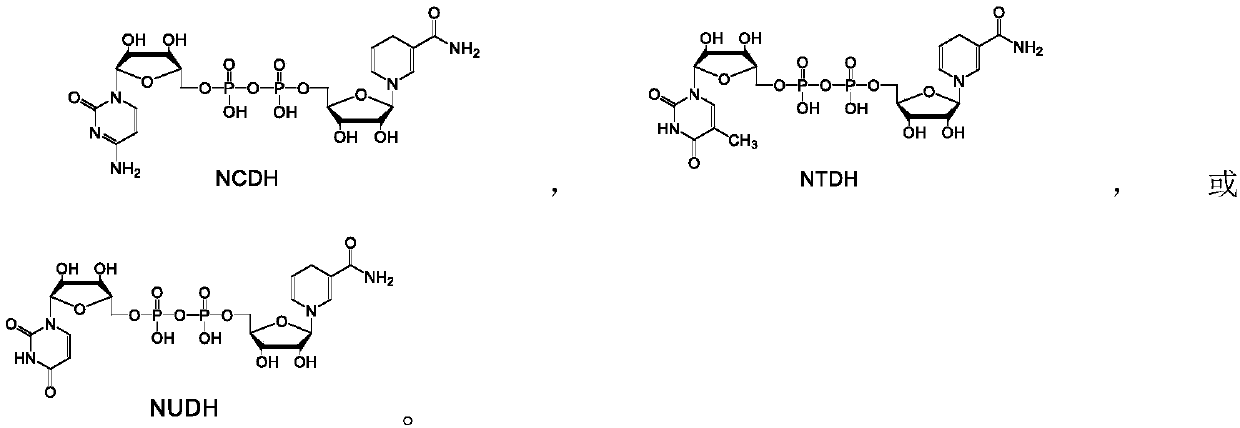

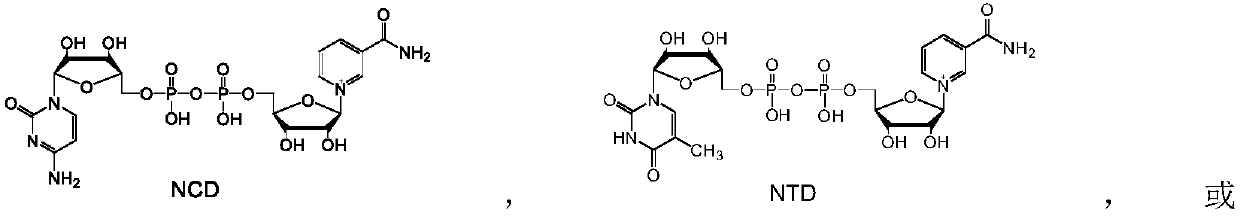

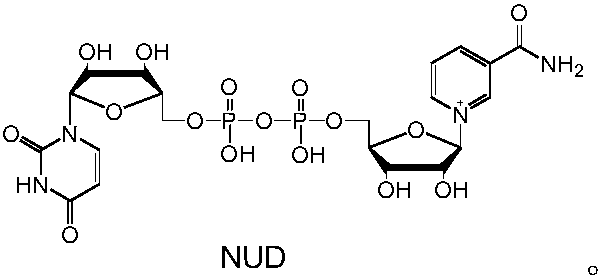

NADH analog dependent cytochrome P450 reductase and application thereof

ActiveCN111218430ACatalytic conditions are mildImprove reaction efficiencyOxidoreductasesFermentationCytochrome P450 reductaseOxidoreductase

The invention discloses an NADH analog dependent cytochrome P450 reductase and an application thereof. An NADH analogue is used as a cofactor and reducing power to catalyze electron transfer and reduce cytochrome P450 to complete catalytic circulation. The enzyme is subjected to fusion expression with different types of cytochrome P450 enzymes to construct the NADH analog-dependent, heterozygous and self-sufficient cytochrome P450 enzyme, the obtained NADH analog-dependent cytochrome P450 enzyme can be coupled with oxidoreductases of a regenerated NADH analogue, and the NADH analog is used tocatalyze corresponding substrates of different families of cytochrome P450 to be converted into products. The NADH analog-dependent cytochrome P450 reductase can be used for constructing a biologicalorthogonal metabolic pathway independent of natural cofactor NAD(P)H to realize uncoupling of P450 enzyme-catalyzed energy consumption and endogenous energy metabolism.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Olefin isomerization catalyst and application thereof

InactiveCN104492484ACatalytic conditions are mildReduce design costHydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsIsomerizationMetal

The invention discloses an olefin isomerization catalyst and an application thereof. The catalyst is an organic liquid of transition metal salt and Lewis acid, the molar ratio of which is ranged from 1: 0.5 to 1: 10. The concentration of the transition metal salt is ranged from 1 mmol / L to 10 mmol / L. The catalyst disclosed by the invention is used for liquid phase catalysis of olefin isomerization and is mild in reaction condition, relatively high in yield, easy to implement and low in cost.

Owner:HUAZHONG UNIV OF SCI & TECH

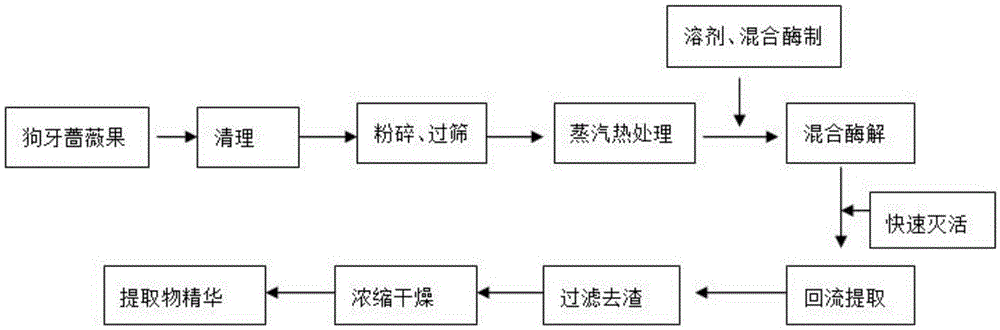

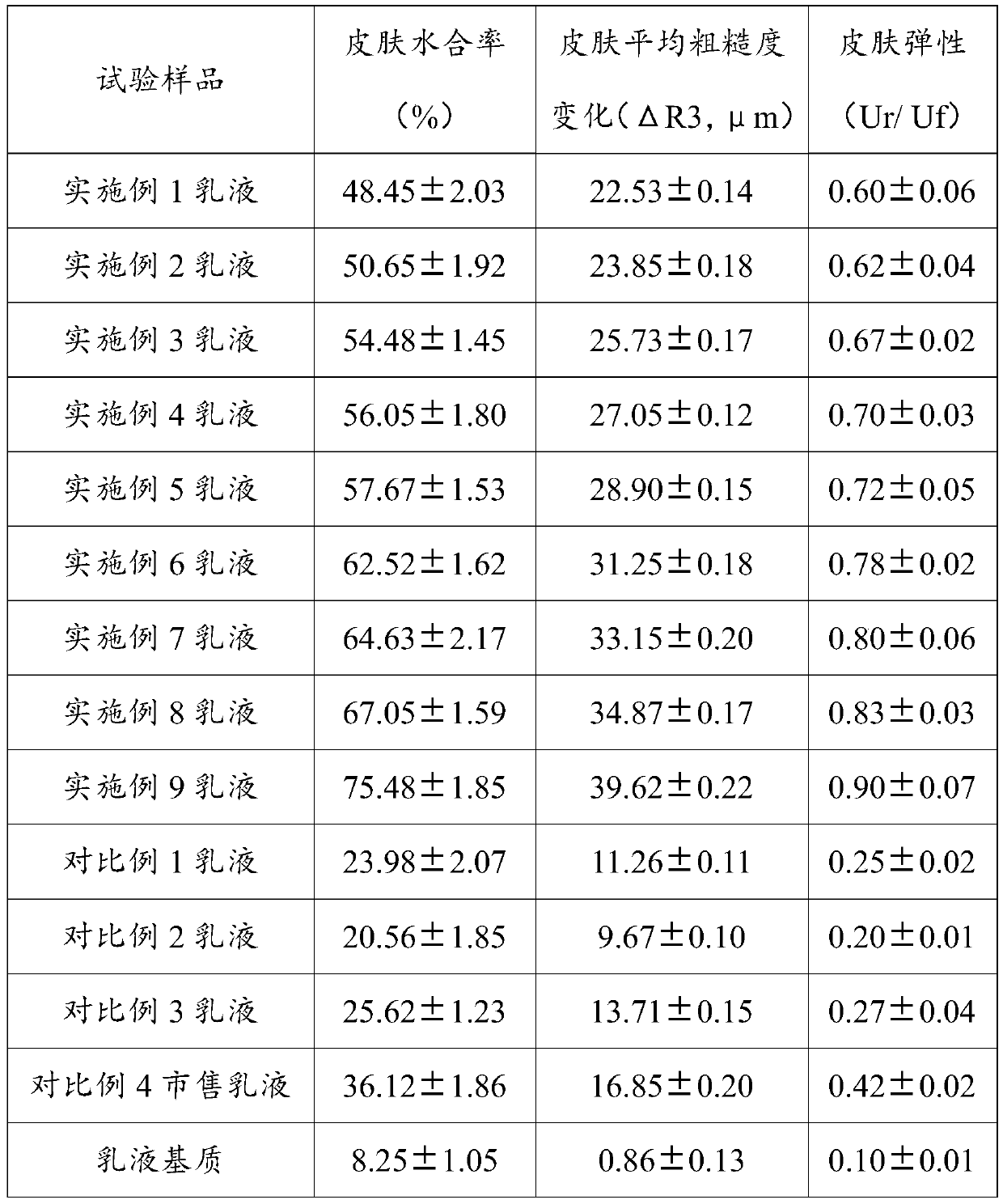

Preparation method and application of rosa canina fruit extract

ActiveCN105456086AImprove performanceMild conditionsCosmetic preparationsToilet preparationsReflux extractionSolvent

The invention relates to the field of daily chemical, in particular to a preparation method of a rosa canina fruit extract and application thereof in a skin care cream. The preparation method mainly comprises the steps that 1, dried rosa canina fruits are subjected to superfine grinding so as to pass through a 100-mesh sieve; 2, a composite biological enzyme is prepared; 3, the ground rosa canina fruits are added into a solvent, then the temperature is increased to 50-55 DEG C, then the composite biological enzyme is added, the pH is adjusted by acid to be 4.5-5.0, after the mixture is stirred to be uniform, enzymolysis is kept for 2 H at the temperature of 50-55 DEG C, then the temperature is rapidly increased to 100 DEG C for rapid inactivation, the temperature is decreased to 80 DEG C 1 MIN after inactivation, and reflux extraction is carried out for 1H; 4, the extract is filtered, deslagged, concentrated and dried to obtain an educt. The method has the advantages of being high in catalysis efficiency, mild in catalysis condition, and capable of lowering energy consumption, reducing pollution and simplifying technological procedures. When the rosa canina fruit extract prepared through the preparation method is applied to the skin care cream, the effects of well moistening, moisturizing and repairing skin can be achieved.

Owner:OPAL COSMETICS HUIZHOU

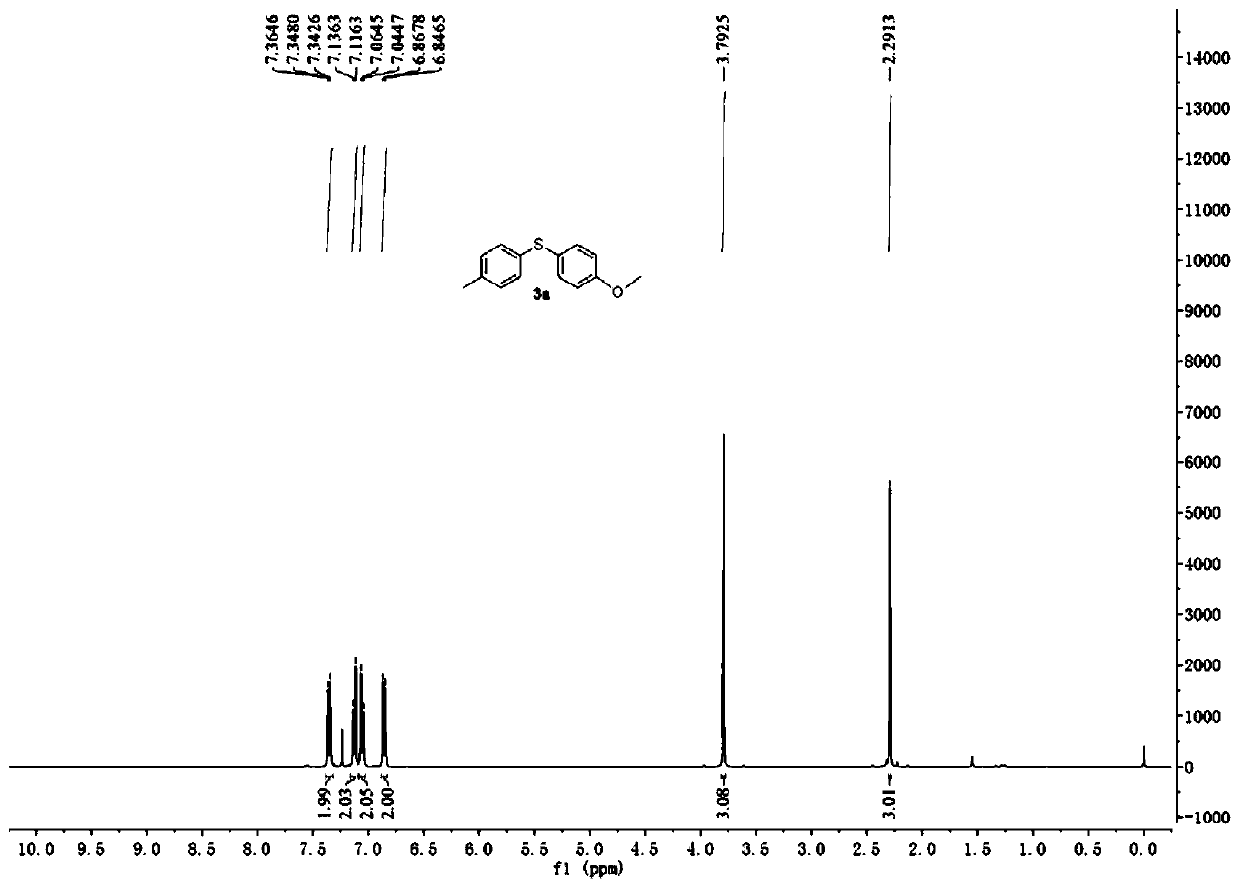

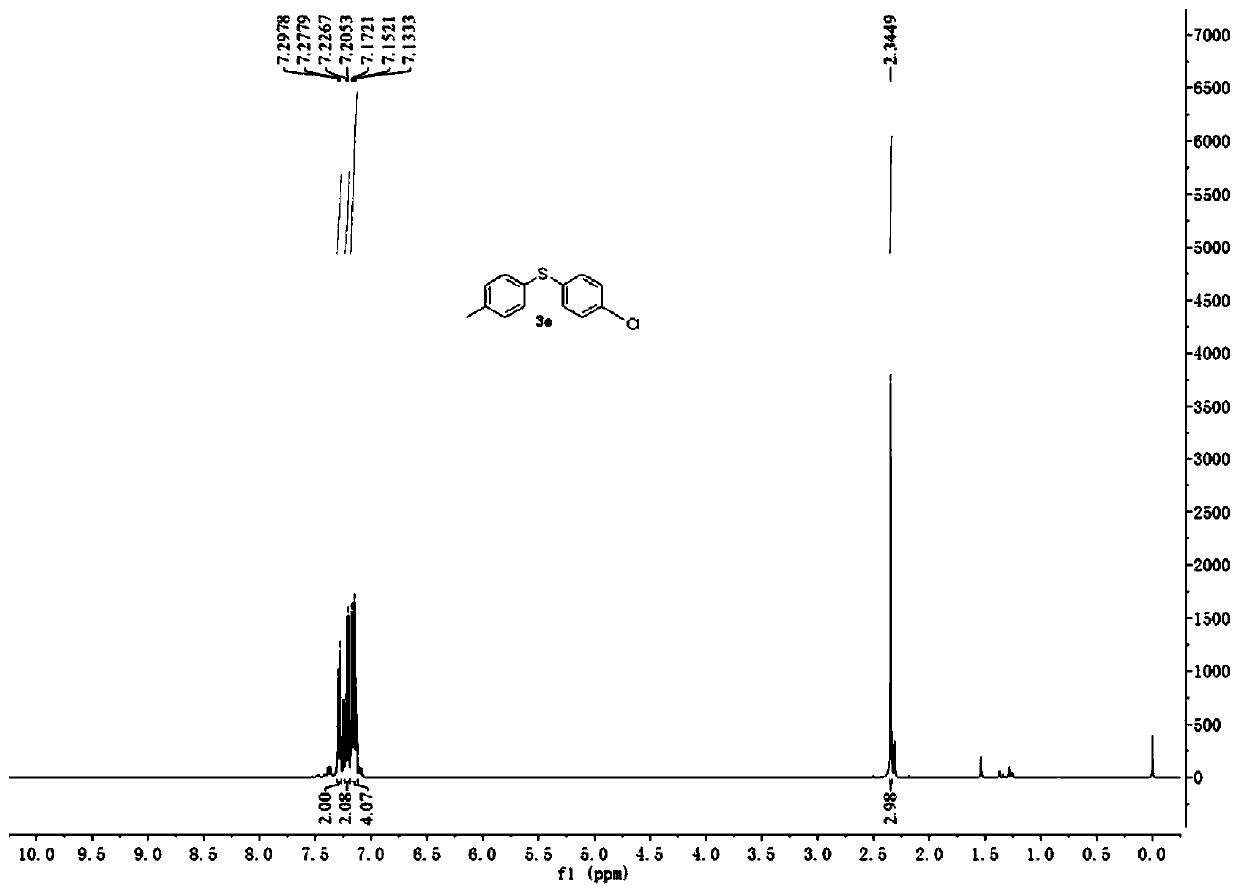

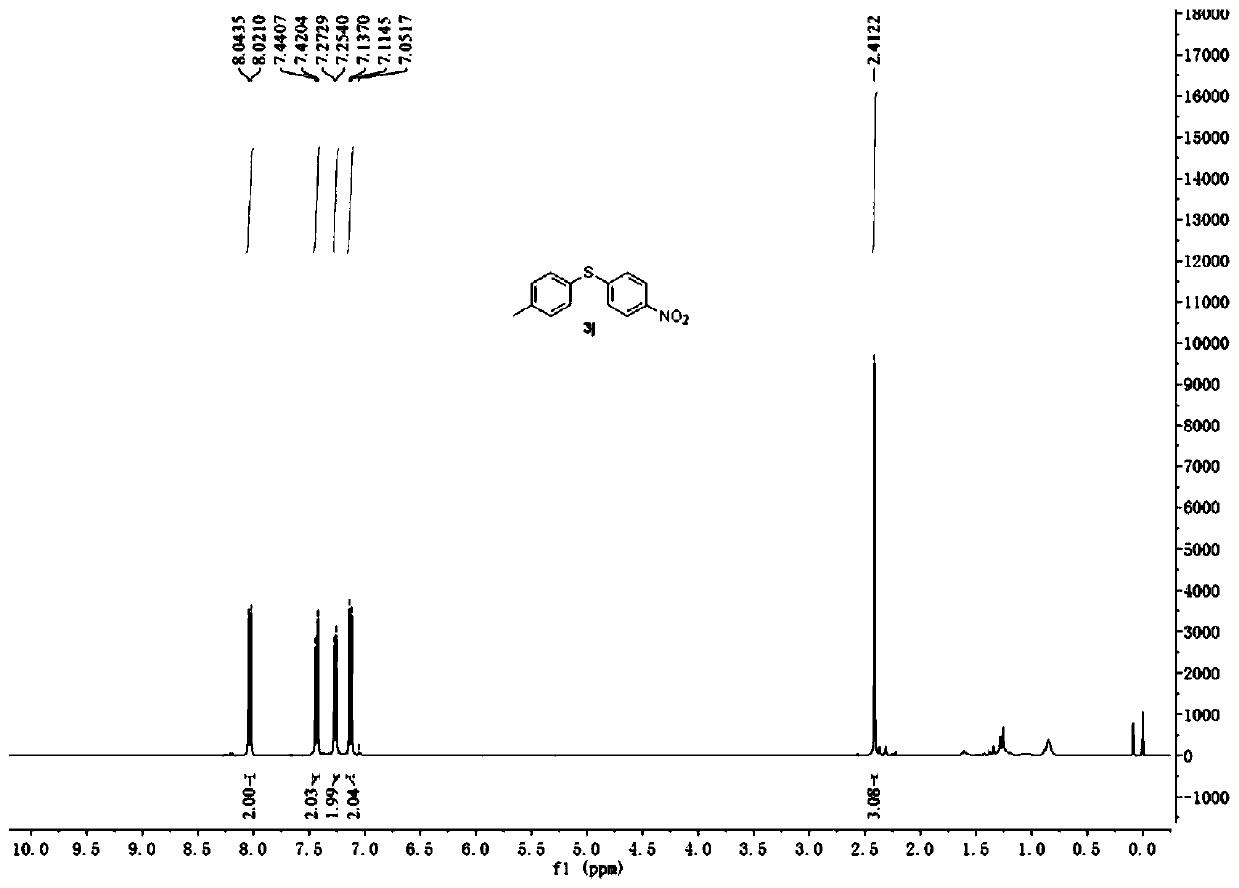

Preparation method of aromatic thioether compound

ActiveCN110563620AEasy access to substratesLow costOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsArylHigh volume manufacturing

The invention discloses a preparation method of an aromatic thioether compound, belonging to the technical field of catalysis. The invention provides a novel environment-friendly method for efficiently synthesizing a thioether derivative; and under the action of a catalyst, thiophenol and an aryl diazonium salt compound are directly coupled under illumination to generate the aromatic thioether compound, wherein the catalyst is cephalosporin. According to the method disclosed by the invention, the cephalosporin is used as the catalyst; catalytic conditions are mild, and the method can be carried out at room temperature under visible light irradiation; the catalytic activity of the catalyst is high, and the thioether compound can be catalytically synthesized with high selectivity; and the yield of the thioether compound can reach 96% or above by virtue of a trace amount of the catalyst. The photocatalyst disclosed by the invention has the advantages of usage of simple and easily available substrate raw materials, environmental friendliness, low cost and very good application prospect, and can be produced on a large scale.

Owner:JIANGNAN UNIV

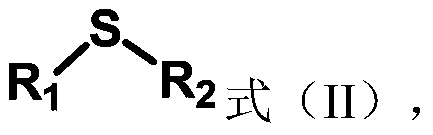

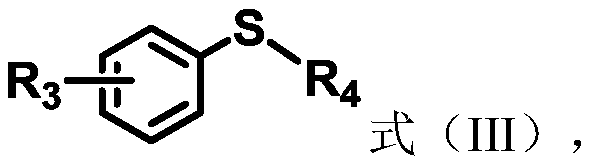

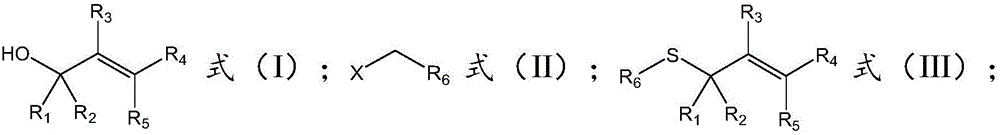

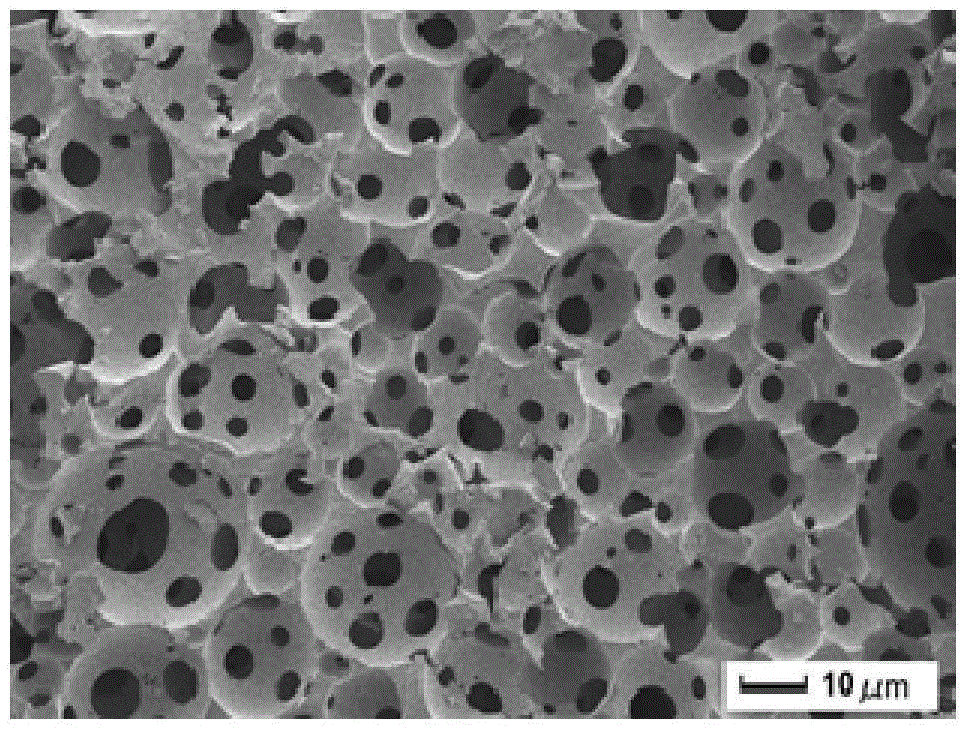

Synthetic method of asymmetrical thioether

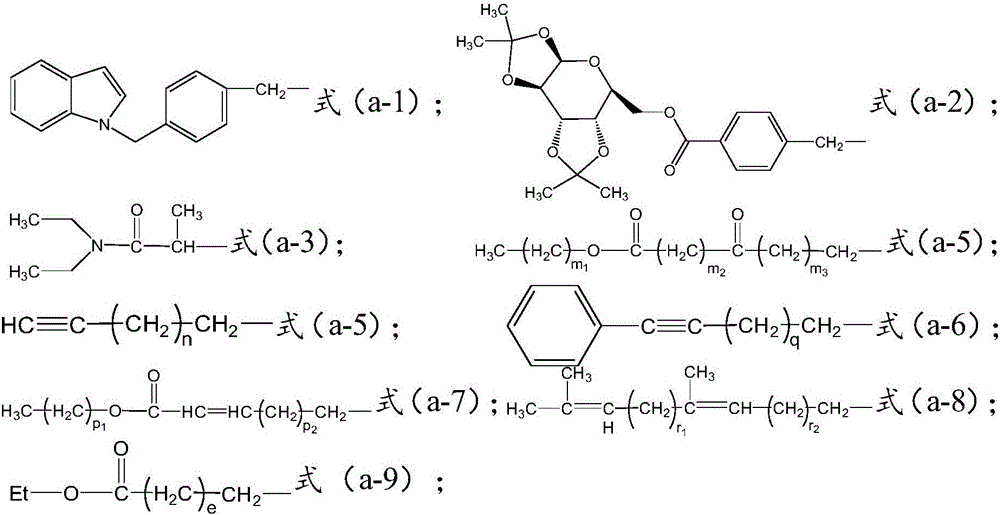

ActiveCN106117096ACatalytic conditions are simpleCatalytic conditions are mildMercapto/sulfide group formation/introductionSugar derivativesHydrogenSulfur

The invention belongs to the field of chemistry, and relates to a synthetic method of asymmetrical thioether. The synthetic method comprises the following steps of (a) under the condition of catalysis of tetrabutyl ammonium halide, enabling a structural compound as shown in a formula (I), a structural compound as shown in a formula (II) and sulfur oxonium salt to react in a solvent so as to obtain the asymmetrical thioether with a structure as shown in formula (III), wherein R1 is selected from phenyl, substituted phenyl, naphtyl, substituted naphtyl, thienyl, or substituted thienyl; R2 is selected from hydrogen, phenyl, substituted phenyl, naphtyl, substituted naphtyl, thienyl or substituted thienyl; or R1, R2 and C connected with R1 and R2 form fluorene or thioxanthene; R3 is selected from hydrogen or an alkyl group; R4 is selected from hydrogen, phenyl, substituted phenyl, naphtyl, substituted naphtyl, thienyl or substituted thienyl; R5 is selected from hydrogen; or R4, R5 and C connected with R4 and R5 form the fluorene or the thioxanthene; R6 is selected form the alkyl group or the substituted alkyl group; and X is selected from C1, Br or I.

Owner:SUZHOU UNIV

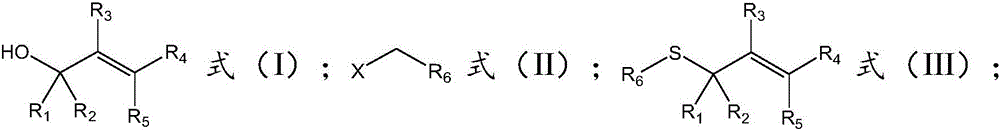

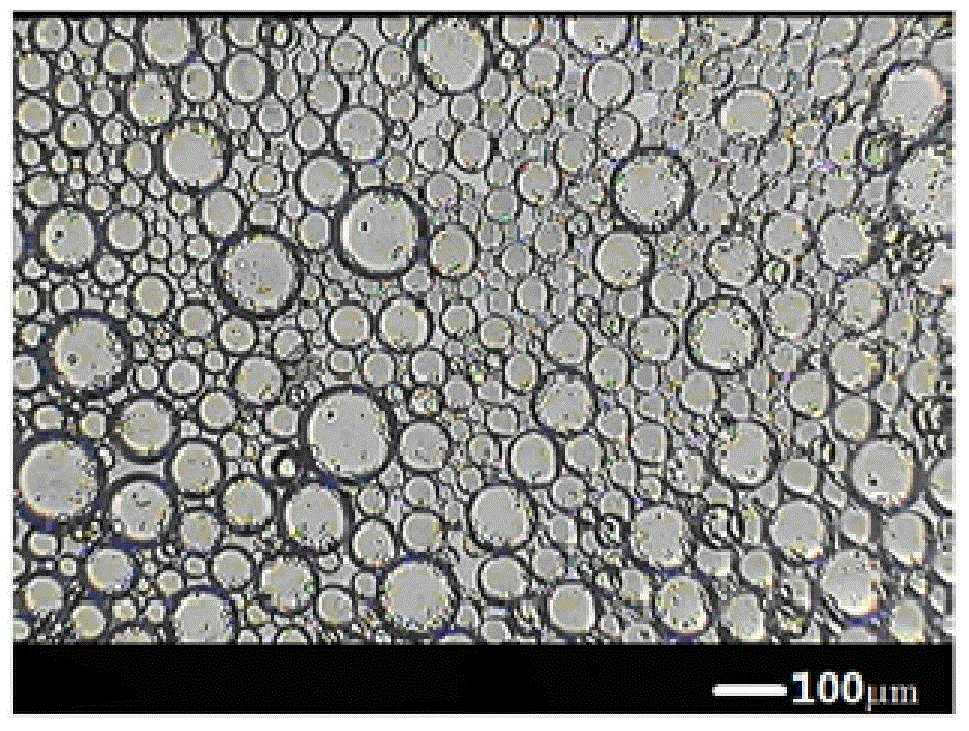

Hydrophobic organic solid acid catalyst and preparation method thereof

InactiveCN104437634AEasy to prepareEasy to recycleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCelluloseBy-product

The invention provides a hydrophobic organic solid acid catalyst and a preparation method thereof, belonging to the field of solid catalysts. The hydrophobic organic solid acid catalyst solves the technical problems that many catalysts are used in the reaction of preparing 5-hydroxymethylfurfural (HMF) by cellulose, the yield of the HMF is not improved and the HMF can be further transformed into a by-product in the reaction. A high-internal-phase emulsion method is adopted for preparing macro-porous organic solid catalyst, and the macro-porous organic solid catalyst is subjected to acid and hydrophobic modification, and then is used as the catalyst for transforming the cellulose into HMF.

Owner:JIANGSU UNIV

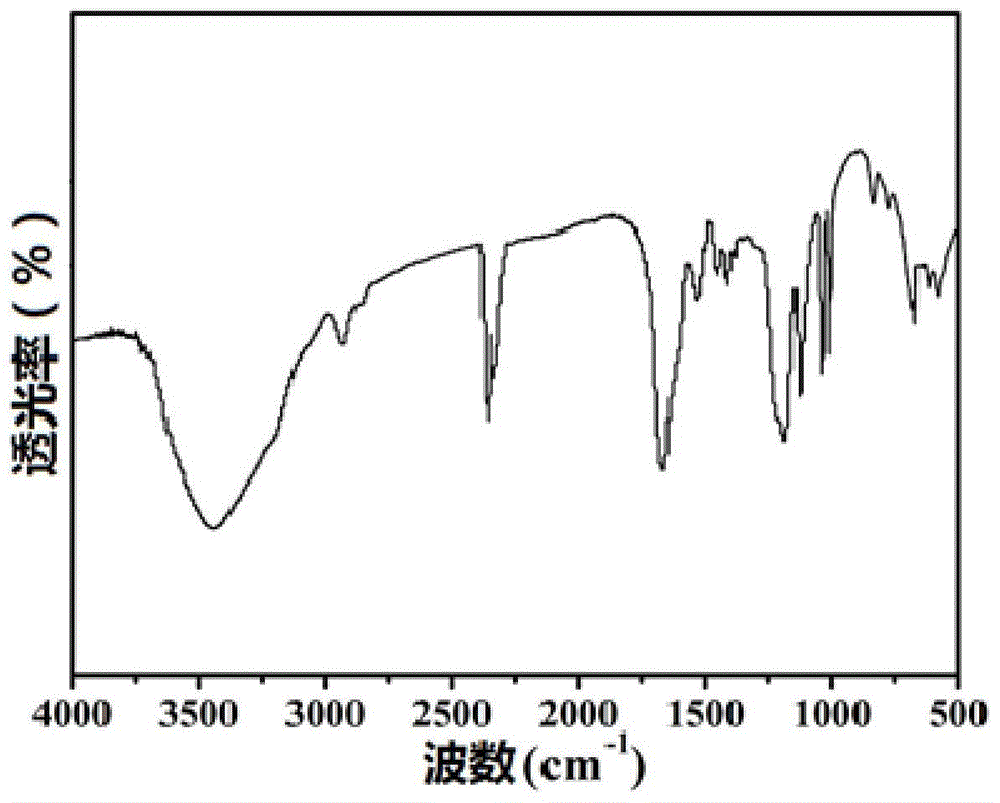

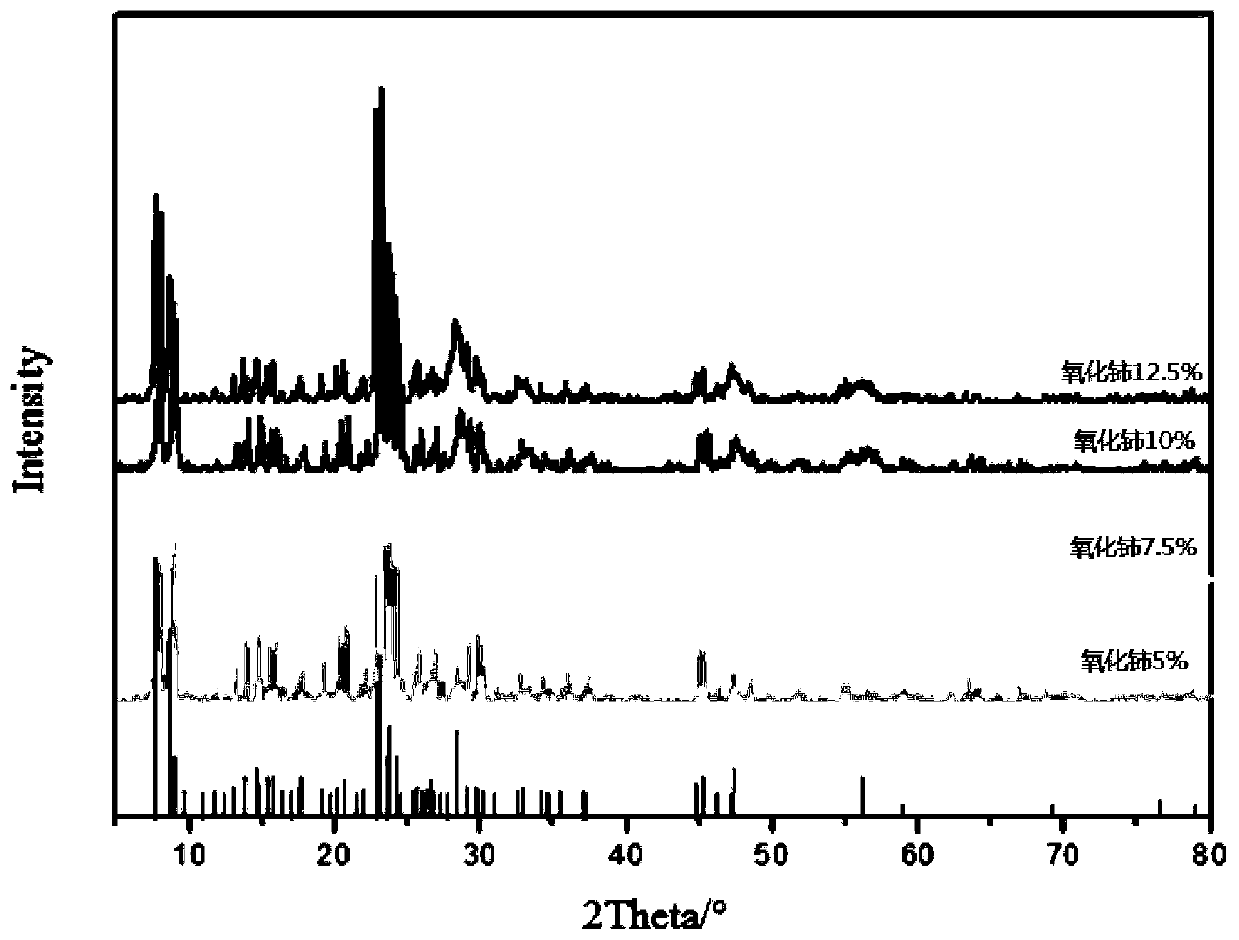

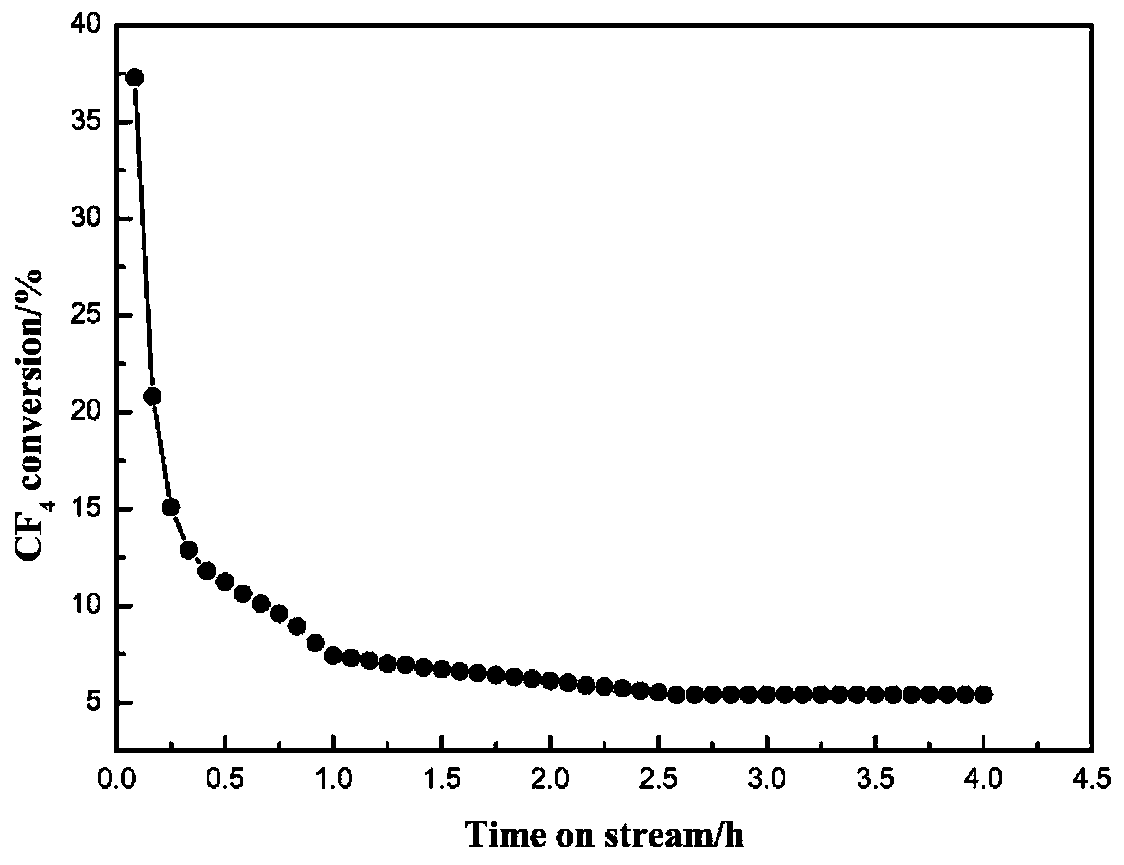

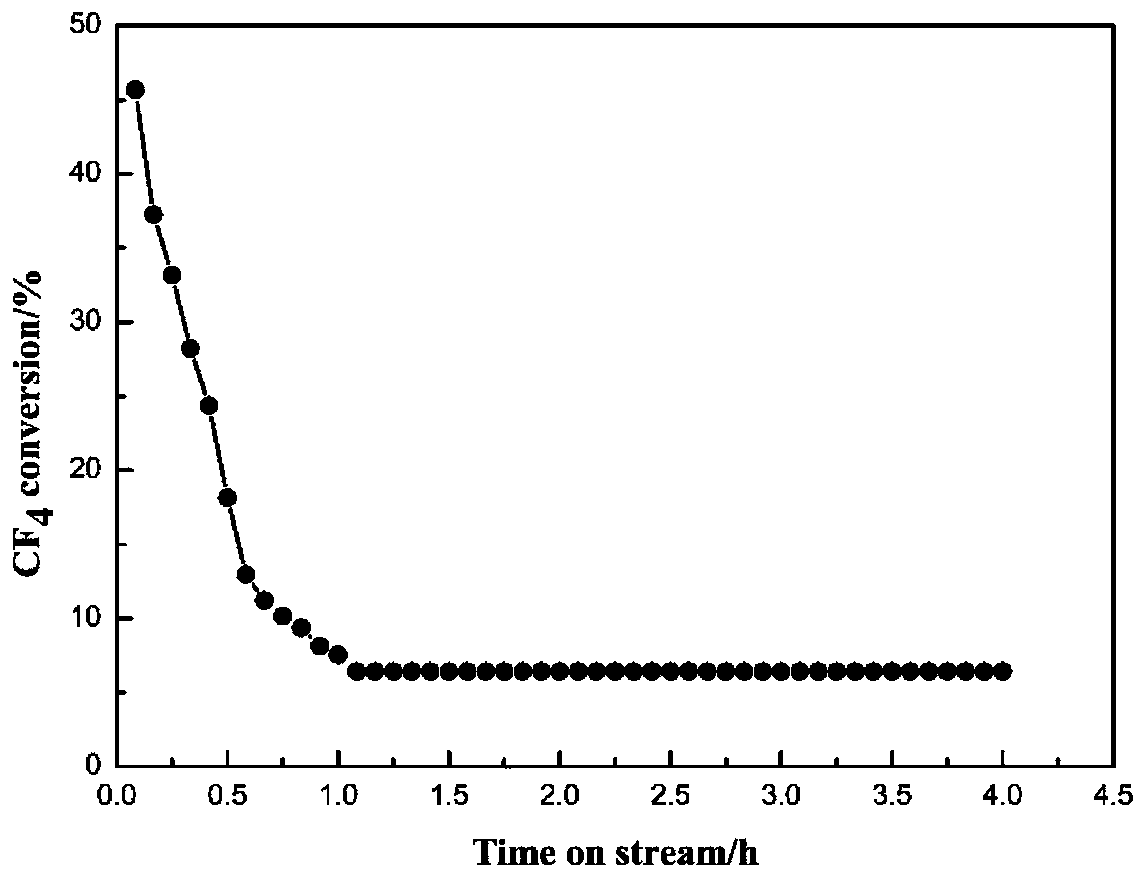

Cerium oxide/HZSM-5 molecular sieve composite catalytic material, preparation method, and application thereof in decomposing carbon tetrafluoride

ActiveCN110813366AHigh catalytic activityGood dispersionGas treatmentMolecular sieve catalystsMolecular sieveCarbon monofluoride

The invention discloses a cerium oxide / HZSM-5 molecular sieve composite catalytic material, a preparation method, and application thereof in catalytic decomposition of carbon tetrafluoride. The composite catalytic material is formed by loading cerium oxide on HZSM-5 molecular sieve, the catalyst can achieve efficient catalytic conversion of carbon tetrafluoride into carbon dioxide under mild conditions, and the defects that a traditional carbon tetrafluoride decomposition catalyst is prone to inactivation at a relatively high temperature and low in low-temperature activity are avoided.

Owner:CENT SOUTH UNIV

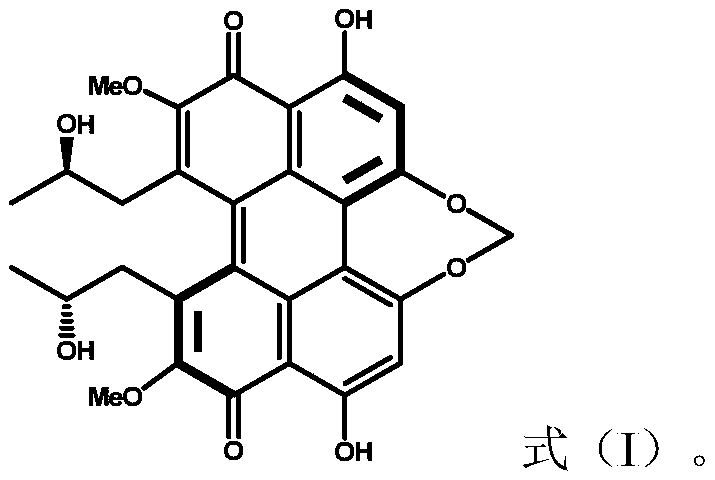

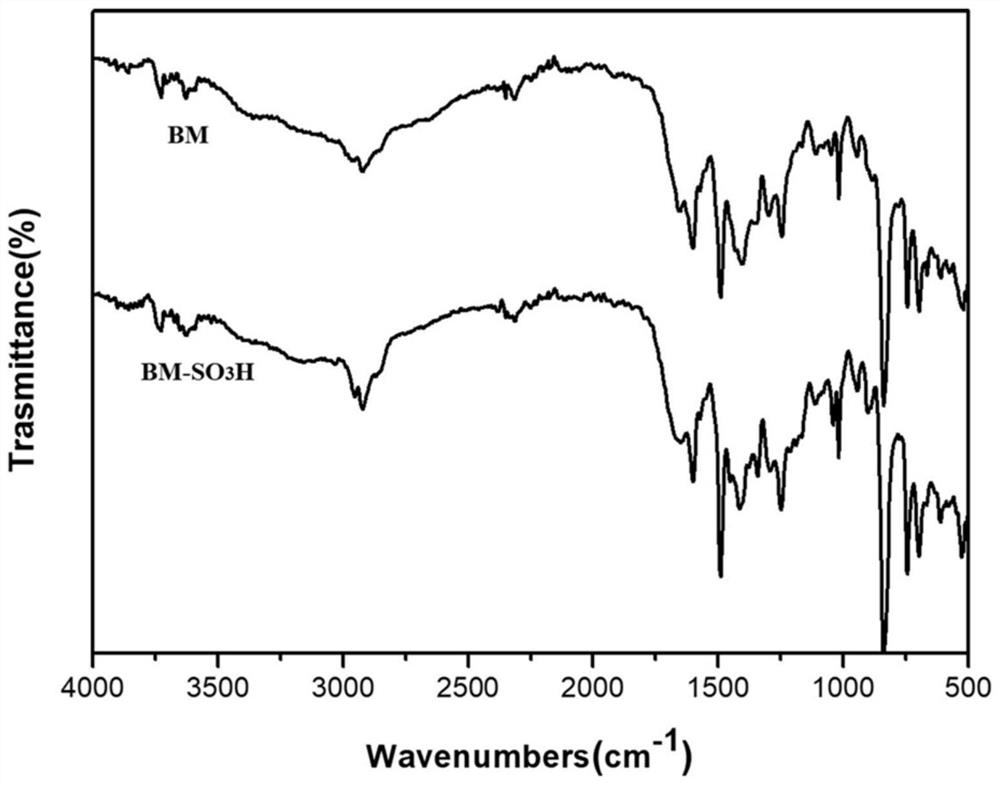

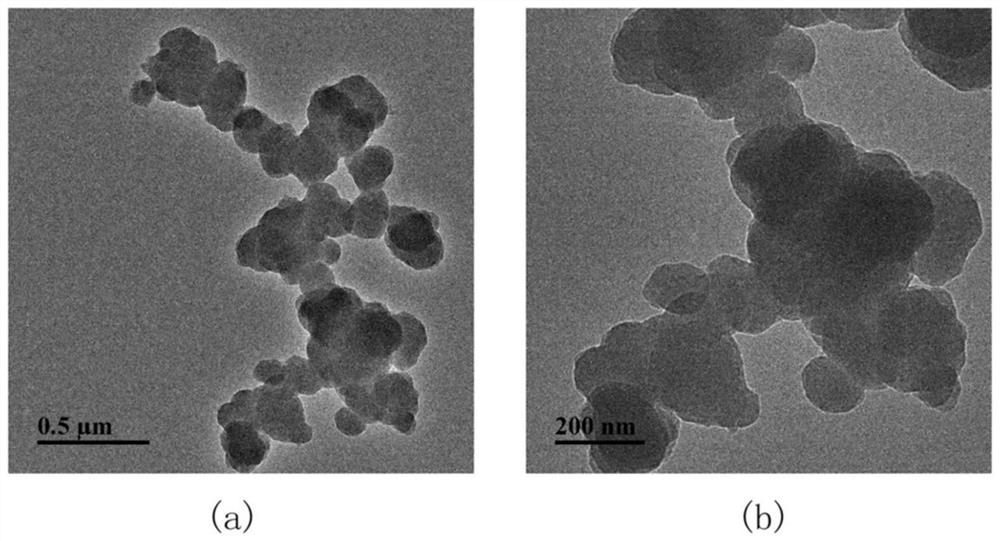

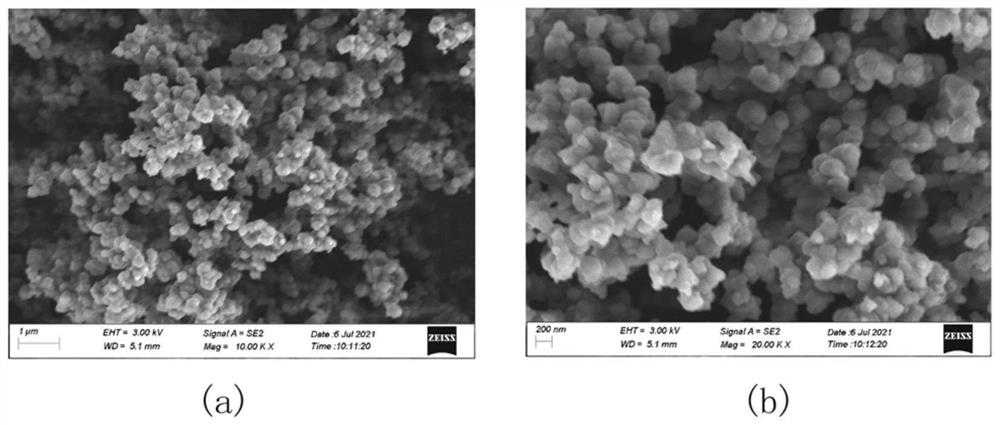

Covalent organic framework material BM-SO3H with acid-base dual functions as well as preparation method and application of covalent organic framework material BM-SO3H

ActiveCN114381006AOptimize synthesis conditionsThe synthesis method is simpleCarboxylic acid nitrile preparationOrganic compound preparationPolymer sciencePtru catalyst

The invention discloses a covalent organic framework material BM-SO3H with acid-base dual functions as well as a preparation method and application thereof, the material has a structure as shown in a formula (I), and the preparation method comprises the following steps: firstly, synthesizing a benzimidazolyl covalent organic framework material BM under the catalysis condition of a photocatalyst; then, the BM and 1, 3-propane sultone are subjected to a ring-opening N atom alkylation reaction, and the covalent organic framework material BM-SO3H is obtained. The material has benzimidazole and propane sulfonic acid structures, so that the material has acid-base dual functions. BM-SO3H is used as a heterogeneous catalyst to catalyze a tandem decarboxylaldehyde Knoevenagel condensation reaction, and the yield can reach 95%-99%. The heterogeneous catalyst BM-SO3H shows excellent catalytic performance, thermal stability and recycling performance, and has a good application prospect.

Owner:JIANGNAN UNIV

Catalyst for isobutylene polymerization and preparation method thereof

InactiveCN106964399AImprove control effectAdaptableMolecular sieve catalystsHydrocarbonsBoron trioxideAluminium salts

The invention discloses a catalyst for isobutylene polymerization and a preparation method thereof. The catalyst is composed of, by weight, 10 parts of amorphous silicon aluminum, 20 parts of molecular sieve, 13 parts of magnesium oxide, 9 parts of sodium carbonate, 13 parts of activated carbon, 8 parts of alkaline aluminum sulfate, 8 parts of kaolin, 17 parts of diboron trioxide, 15 parts of iron trioxide, 25 parts of nano zinc oxide particles and 8 parts of calcium oxide. The catalyst has the advantages that the catalyst prepared by the method has high control ability on polymerization degree of isobutylene and can only directionally catalyze isobutylene to be diisobutylene, triisobutylene and tetraisobutylene, and the catalyst has low requirements on raw materials and high adaptability.

Owner:SHANDONG CHENGTAI CHEM IND

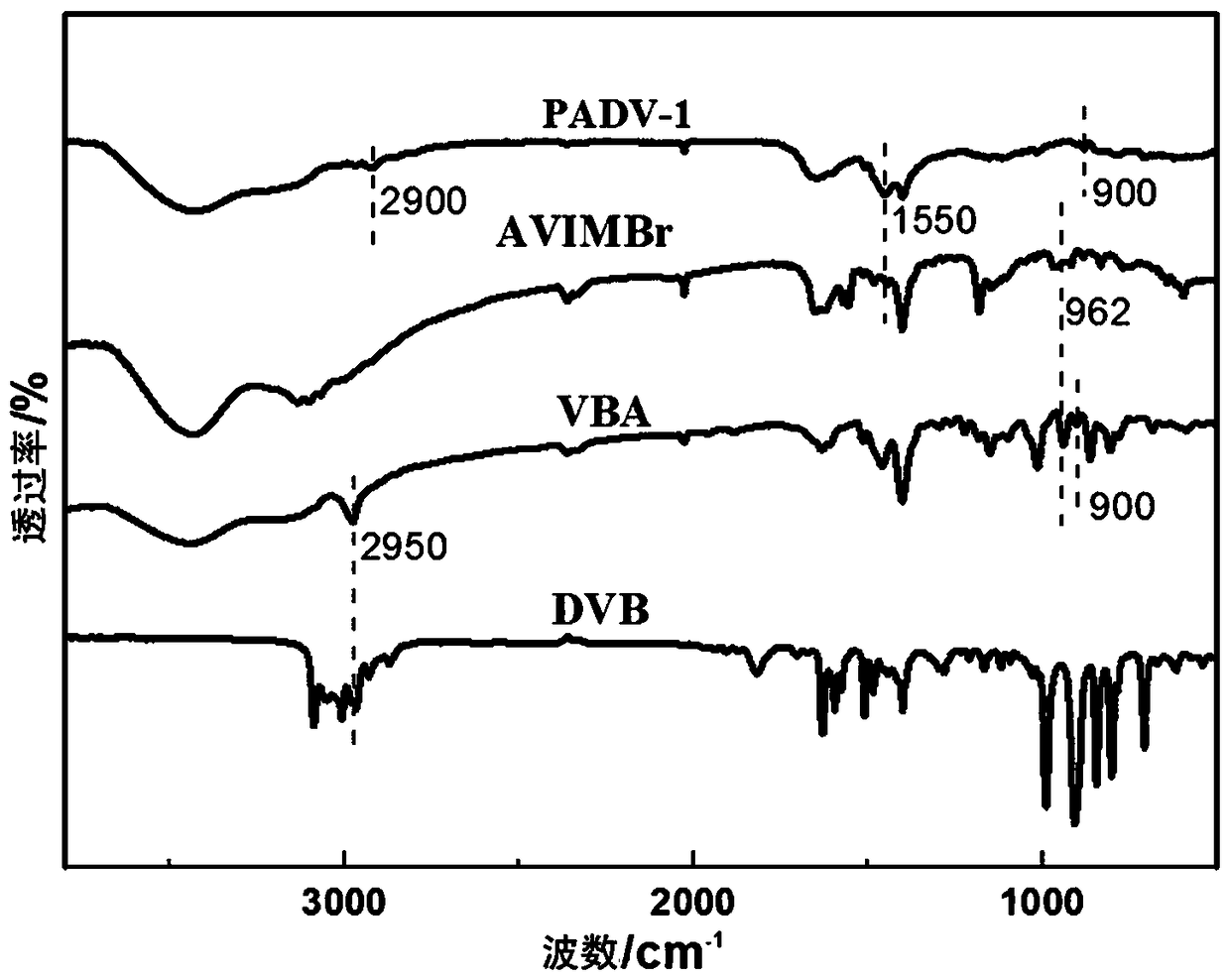

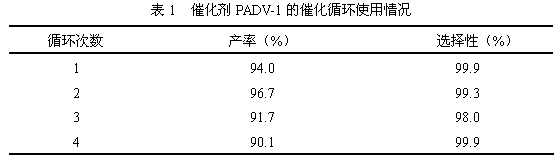

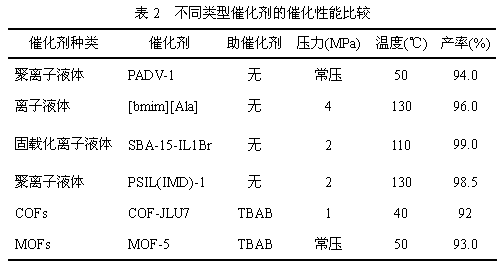

Polyionic liquid catalyst for catalytic conversion of CO2 at normal pressure and preparation method of polyionic liquid catalyst

ActiveCN109364993ACatalytic conditions are mildImprove recycling rateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventIon

The invention discloses a polyionic liquid catalyst, an amino ionic liquid 1-vinyl-3-ethylamino imidazole bromate and a quaternary ammonium ionic liquid vinyl benzyl triethyl ammonium chloride are taken as the active components, divinyl benzene is taken as a skeleton, free radical polymerization is used to prepare and obtain a polyionic liquid material, the excellent synergistic effect between theamino ionic liquid and the quaternary ammonium ionic liquid is used, the catalytic conversion of CO2 is efficiently conducted without solvents or additional cocatalysts at the normal pressure to prepare cyclic carbonate, the stability of the catalyst is good, and the catalyst can be recycled.

Owner:TAIYUAN UNIV OF TECH

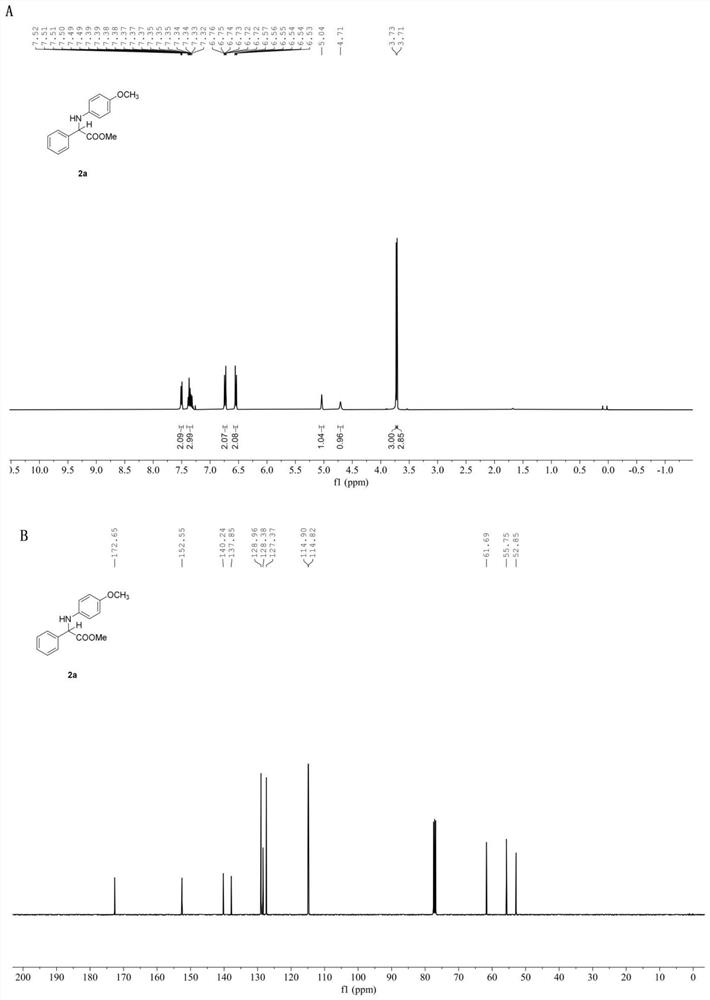

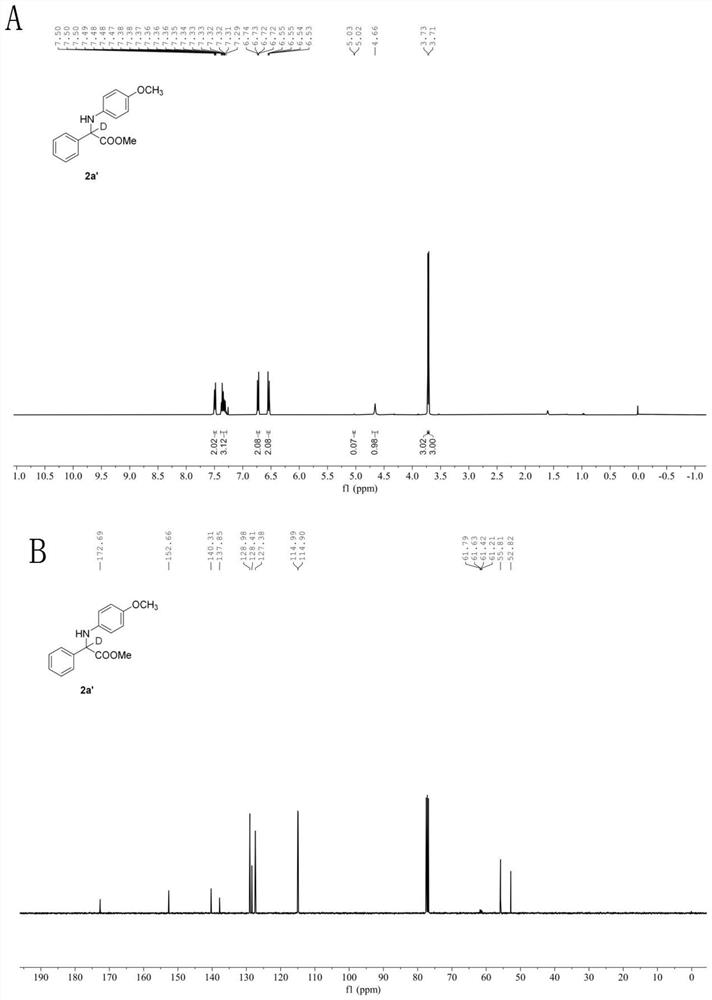

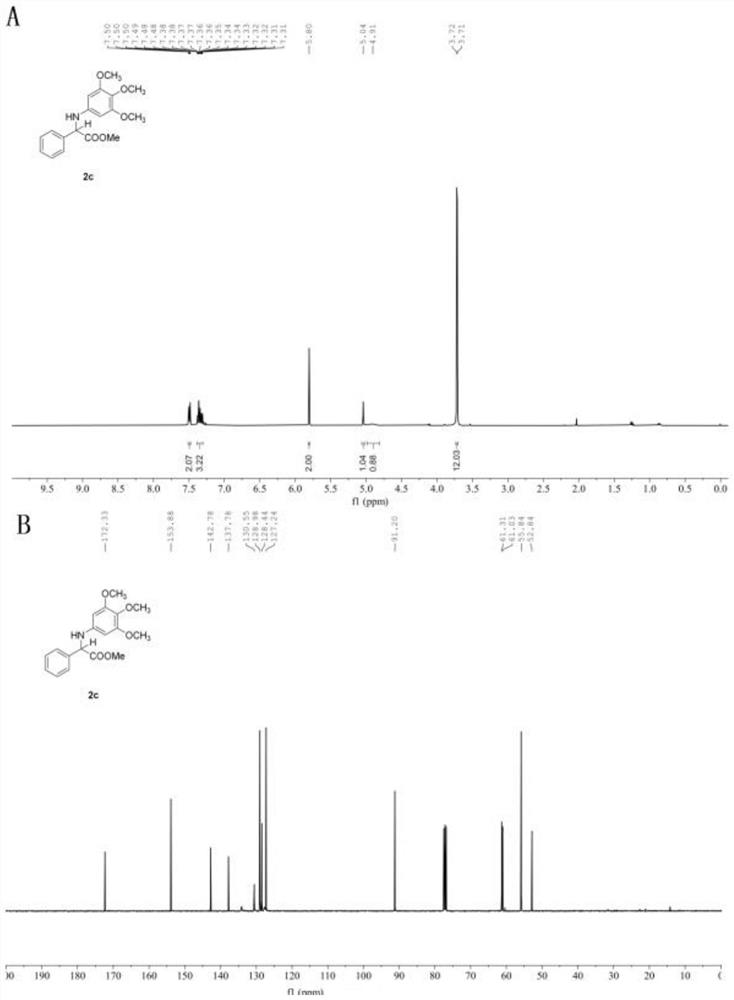

Preparation method of amino-acid ester or deuterated amino-acid ester compound

InactiveCN114436871ATransfer hydrogenationReduce manufacturing costOrganic compound preparationAmino-carboxyl compound preparationPhotosensitizerOrganic solvent

The invention discloses a preparation method of an amino-acid ester or deuterated amino-acid ester compound, which comprises the following steps of: adding a photosensitizer and an organic solvent into a reaction container by taking imidic ester, silane and water or heavy water as initial raw materials, carrying out stirring reaction under the irradiation of blue light, detecting that the reaction raw material imidic ester completely disappears by TLC thin-layer chromatography, and filtering to obtain the deuterated amino-acid ester compound. And stopping stirring, removing the volatile solvent, carrying out silica gel column chromatography or neutral alumina column chromatography, and carrying out vacuum concentration to obtain the target amino-acid ester or deuterated amino-acid ester compound. According to the method, blue light catalysis is used for replacing traditional precious metal catalysis, silane and water are used for replacing a traditional hydrogen source for the first time, transfer hydrogenation of the imidic ester compounds is achieved, cheap deuterium water is used as a deuterium source, a series of deuterated amino-acid ester compounds can be prepared, and therefore the production cost is greatly reduced; the method provided by the invention has the advantages of mild catalytic conditions, simple catalytic system, high reaction selectivity, high safety and high synthesis efficiency, and is worthy of popularization and application.

Owner:YUNNAN MINZU UNIV

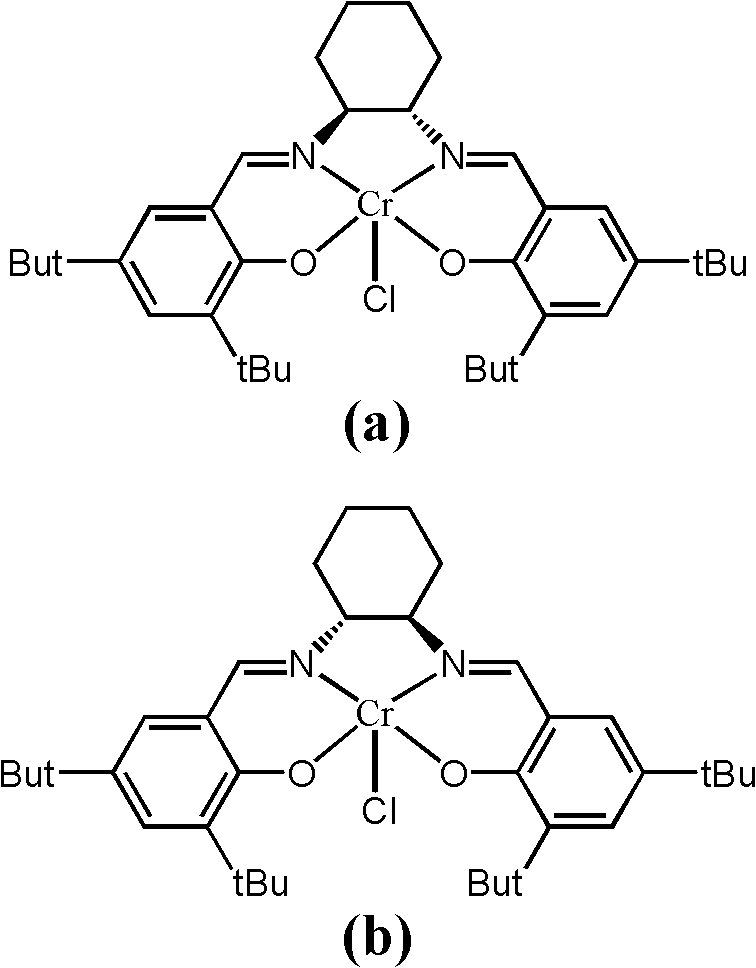

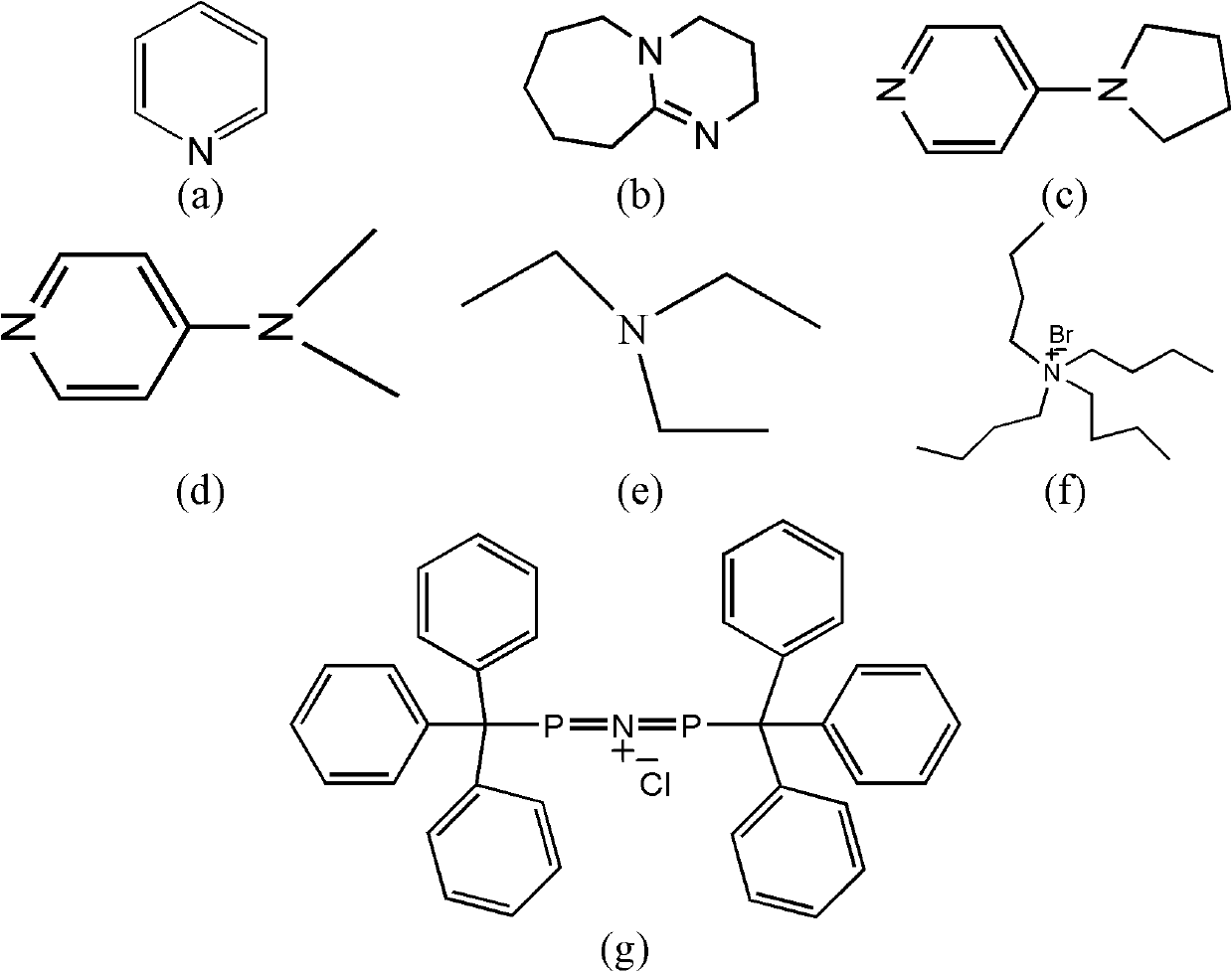

Catalyst for splitting racemic epoxyalkane and application thereof

InactiveCN103301882AReduce dosageReduce wasteGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsQuaternary ammonium cationNitrogen

The invention relates to a catalyst for splitting racemic epoxyalkane. The catalyst is composed of nitrogen-containing organic alkali or quaternary ammonium salt, and Cr (Salen) [(R,R) / (S,S)-N,N'-Bis(3,5-di-tert-butylsalicylidene)-1,2-cyclohexanediamino chromium (III) chloride], the mole ratio of the organic alkali or quaternary ammonium salt to the Cr (Salen) is 0.1-10; in the process of carrying out asymmetric ring-opening splitting of the racemic epoxyalkane, the splitting conversion rate of the catalyst to epoxyalkane can be greater than 49%, and the ee value of a split product 1-azido-2-trialkyl siloxane can be over 90%. The catalyst mainly solves the problem that previous catalytic racemic epoxyalkane is low in asymmetric ring-opening reaction activity, large in application amount of the catalyst and low in enantioselectivity, realizes the efficient splitting of racemic epoxyalkane, and can obtain high-purity chiral epoxyalkane and trialkyl siloxane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Copper-based catalyst and application thereof

InactiveCN105457634AHigh catalytic efficiencyCatalytic conditions are mildMetal/metal-oxides/metal-hydroxide catalystsSodium metasilicateCatalytic effect

The present invention discloses a copper-based catalyst, which is prepared by reaction of sodium metasilicate and a copper source in an organic phase environment. Compared with the prior art, the copper-based catalyst of the present invention has the catalytic copper dispersedly immobilized on a silica gel carrier to expand the area of contact with the reaction substrate materials. Compared with the prior art, the copper-based catalyst has higher catalytic efficiency, requires more moderate catalytic conditions, and is in favor of industrial production. At the same time, the method of the present invention is completed under the condition of pure organic phase; by contrast, the obtained copper catalyst has higher catalytic efficiency than the one obtained in general water content conditions.

Owner:PURESCI ENVIRONMENTAL TECH CO LTD

A kind of preparation method of lithium-supported silica gel catalyst

InactiveCN104190396BHigh catalytic efficiencyCatalytic conditions are mildMetal/metal-oxides/metal-hydroxide catalystsLithium chlorideSilica gel

The invention discloses a preparation method of a lithium-loaded silica gel catalyst, which is prepared by gelling silicic acid hydrosol and lithium chloride powder. The invention disperses and fixes the catalytic lithium on the silica gel carrier, and compared with the prior art, the catalytic efficiency is higher, the required catalytic conditions are milder, and it is beneficial to industrial production.

Owner:PURESCI ENVIRONMENTAL TECH CO LTD

Preparation method of dechlorination catalyst

InactiveCN105251481AHigh catalytic efficiencyCatalytic conditions are mildMetal/metal-oxides/metal-hydroxide catalystsSodium metasilicateCatalytic effect

The invention discloses a preparation method of a dechlorination catalyst. The dechlorination catalyst is obtained in the mode that sodium metasilicate and a metal source react under the environment of an organic phase. Compared with the prior art, the dechlorination catalyst is used for dispersing and fixing palladium and aluminum which have a catalytic effect to a silica gel carrier, and the contact area between the dechlorination catalyst and reaction bed charge is increased. Compared with the prior art, the catalytic efficiency of the dechlorination catalyst is higher, the needed catalytic condition is more moderate, and industrial production is facilitated. Meanwhile, the method is completed under the condition of a pure organic phase, and according to comparison with the common water containing condition, and the catalytic efficiency of the obtained dechlorination catalyst is higher.

Owner:PURESCI ENVIRONMENTAL TECH CO LTD

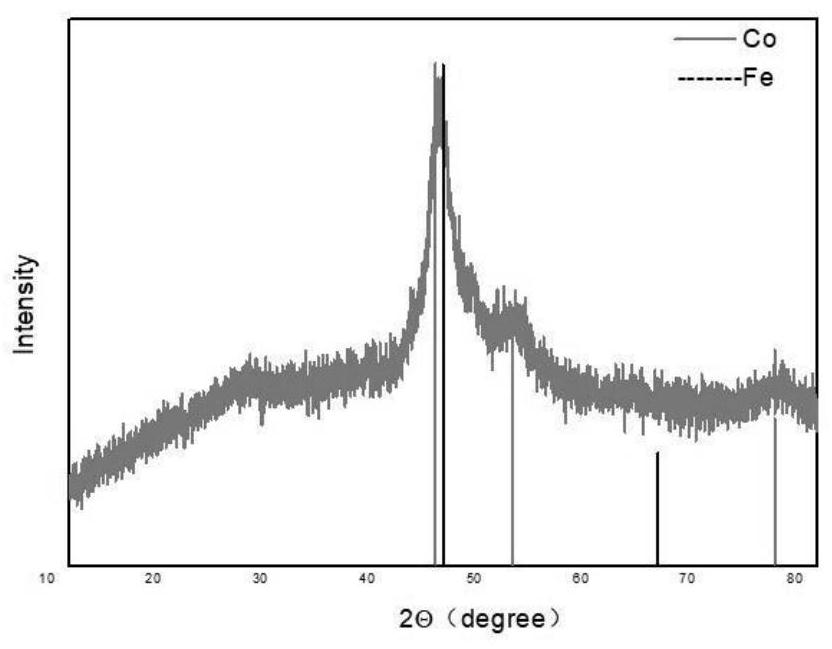

FeCo/N-C nano composite material as well as preparation method and application thereof

ActiveCN114540840ALarge specific surface areaHigh catalytic activityEnergy inputElectrode shape/formsPtru catalystNanocomposite

The invention relates to the field of catalysts, and provides a FeCo / N-C nano composite material which is in a rod shape, has a porous structure and is high in catalytic efficiency aiming at the problem that the reaction condition of the existing synthetic ammonia catalyst is harsh. The invention also provides a preparation method of the catalyst, which comprises the following steps: a, dissolving Fe salt, Co salt and ligand in a solvent, heating for reaction, and separating out precipitate after the reaction is finished to obtain a precursor; and b, calcining the precursor to obtain the FeCo / N-C nano composite material. The preparation method is simple, and the prepared catalyst is high in purity. The invention also provides application of the catalyst in electrocatalytic nitrogen fixation ammonia synthesis.

Owner:HANGZHOU NORMAL UNIVERSITY

Dechlorination catalyst and application thereof

InactiveCN105289590AHigh catalytic efficiencyCatalytic conditions are mildOrganic chemistryOrganic compound preparationSodium metasilicateSilica gel

The invention discloses a dechlorination catalyst. The dechlorination catalyst is prepared by a reaction of sodium metasilicate and a metal source in an organic phase environment. Compared with the existing dechlorination catalyst, the dechlorination catalyst provided by the invention can dispersedly fix palladium and aluminum with catalysis effects to a silica gel carrier so that a contact area of the catalysis ingredients and a reaction substrate is increased. Compared with the existing dechlorination catalyst, the dechlorination catalyst provided by the invention has higher catalysis efficiency, needs mild catalysis conditions and is conducive to industrial production. The catalysis method utilizing the dechlorination catalyst is finished under the pure organic phase condition. Compared with the common water-containing condition, the pure organic phase condition improves dechlorination catalyst catalysis efficiency.

Owner:PURESCI ENVIRONMENTAL TECH CO LTD

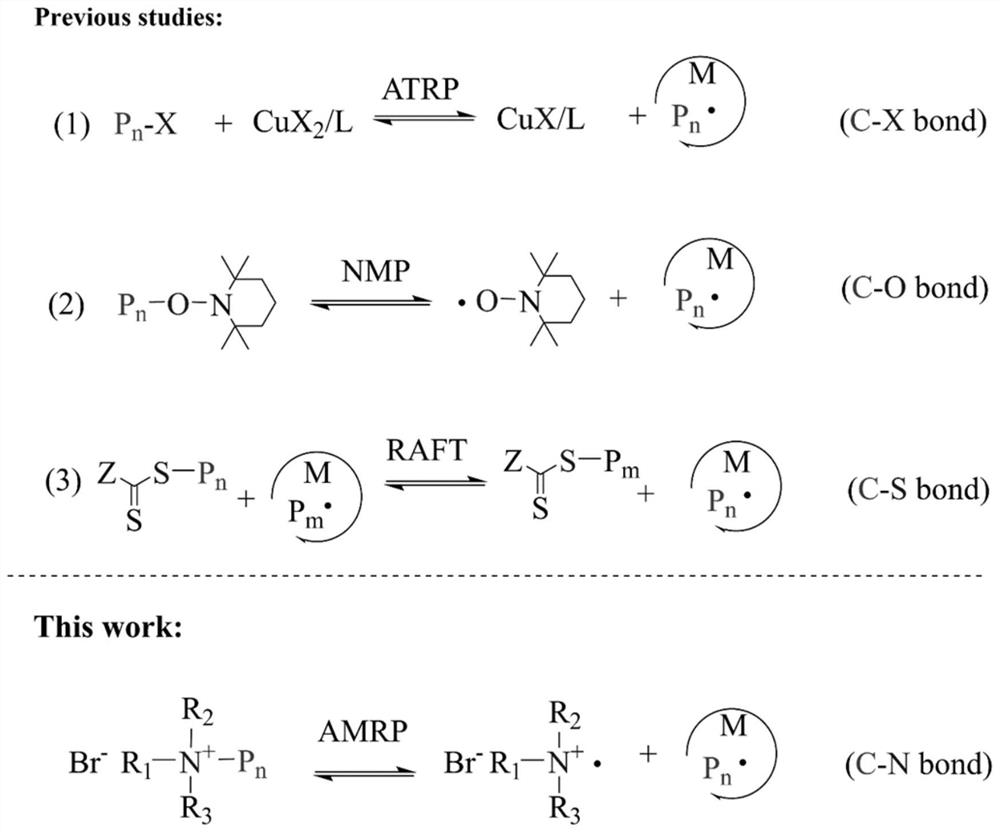

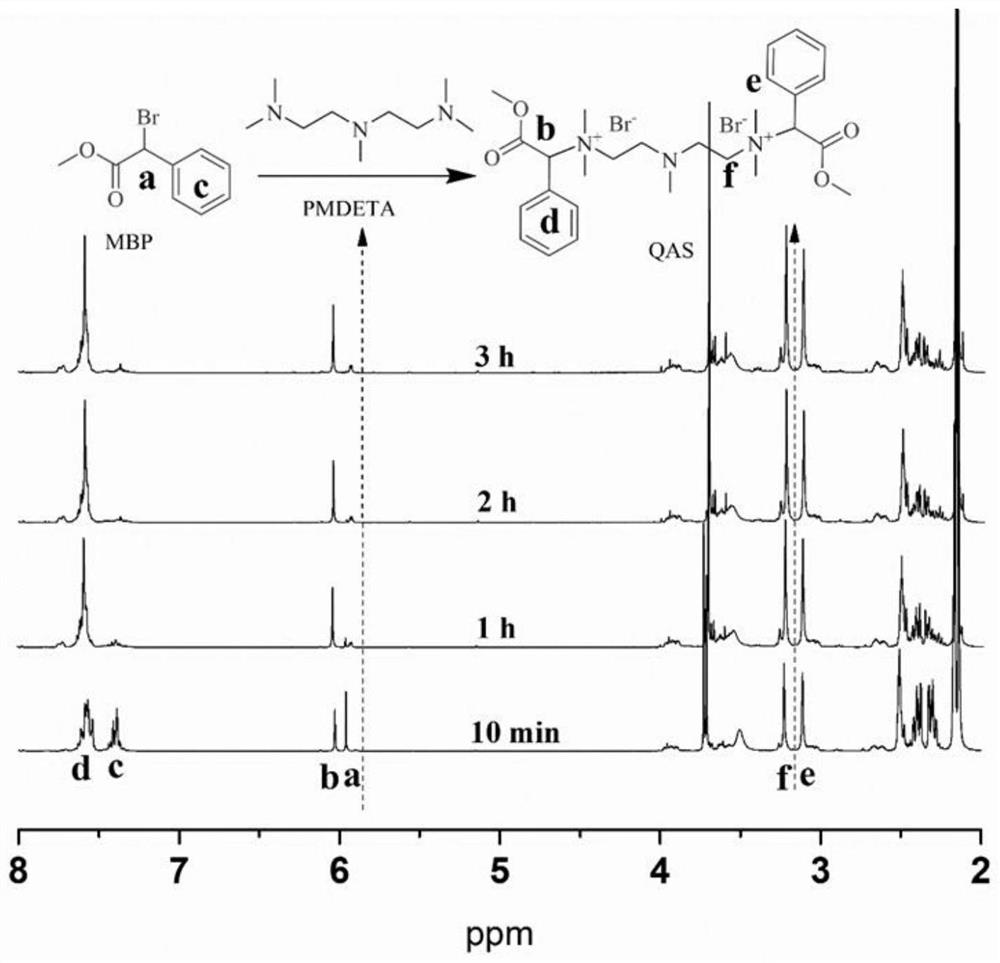

A Controlled Radical Polymerization Method Based on C-N Bond Breakage

The invention discloses a controllable free radical polymerization method based on C-N bond breaking, comprising the following steps: dissolving polymerized monomers, halogenated hydrocarbons and tertiary amines in an organic solvent, and dissolving the obtained solution under a protective atmosphere react under light conditions to obtain a polymer; wherein, the polymerized monomer is a methacrylate monomer or an acrylamide monomer, and the halogenated hydrocarbon is selected from methyl α-bromophenylacetate, iso A kind of in hydroxyethyl bromobutyrate, methyl 2-bromoisobutyrate, the tertiary amine is selected from triethylamine, pentamethyldiethylenetriamine, three (2-dimethylaminoethyl) A sort of. The invention proposes a brand-new reversible deactivation free radical polymerization method, and the catalytic system has the advantages of no metal ion participation, mild catalytic conditions, high catalytic activity and the like.

Owner:SUZHOU UNIV

A kind of metal oxide catalyzes the method for synthesizing polyethylene glycol phosphonate

ActiveCN107814939BReduce acidityIncrease productivityFireproof paintsDimethyl methylphosphonatePtru catalyst

The invention relates to a method for synthesizing poly(oxy-1,2-ethanediyl)methylphosphonate through catalysis by virtue of a metallic oxide and belongs to the technical field of preparation of flameretardants. The method comprises the following steps: uniformly mixing the metallic oxide, dimethyl methylphosphorate and ethylene glycol to obtain a heterogeneous mixture, adding the mixture into a three-necked flask, adding stirrers into the three-necked flask, placing the three-necked flask on an electromagnetic heating jacket at the temperature of 160-170 DEG C, stirring at constant temperature, distilling for 2-4 hours, and filtering, so that the poly(oxy-1,2-ethanediyl)methylphosphonate is obtained. The method provided by the invention has the advantages that reaction time is greatly shortened, reaction can be finished within 2-4 hours, the reaction time is almost the same compared with an equivalent excellent ionic liquid catalyst, but cost is lower, and catalytic conditions are milder. In the industry, the ionic liquid catalyst needs to carry out intermittent operation by adopting a kettle type reaction system, and the metallic oxide can carry out continuous operation, so thatproduction efficiency of industrial production of poly(oxy-1,2-ethanediyl)methylphosphonate is improved, and economic benefit is further improved.

Owner:NORTHEAST FORESTRY UNIVERSITY

A composition containing seed extract and its preparation method

ActiveCN106727136BHigh catalytic efficiencyReduce extraction timeCosmetic preparationsToilet preparationsBiotechnologySoya bean

The invention discloses a composition containing seed extractives, and aims to provide a composition with the effects of moisturizing and hydrating, resisting inflammation and relieving and resisting aging. The composition is mainly prepared from the following components: 10 to 20 parts of millet seeds, 10 to 20 parts of quince seeds, 8 to 15 parts of abelmosk seeds and 5 to 12 parts of wild soybean seeds. The composition belongs to the technical field of cosmetics.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

Method for producing adenosincoenzyme vitamin B12 by enzyme catalysis

InactiveCN100430485CHigh catalytic efficiencyCatalytic reaction price adjustment is simpleFermentationAdenosineVitamin B12

Owner:吉林省奇健生物技术有限公司

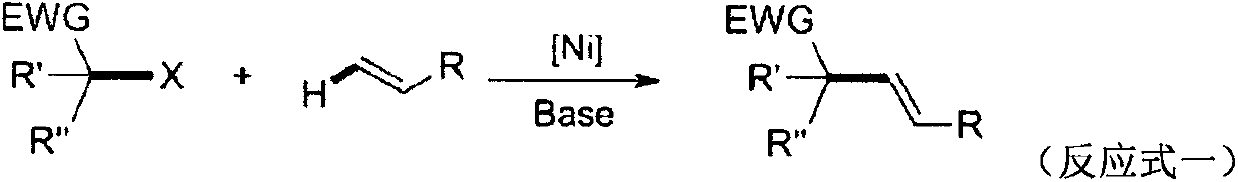

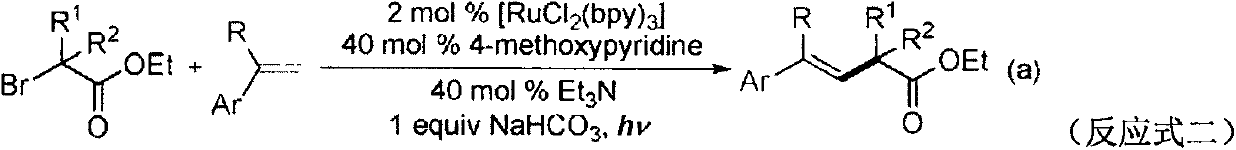

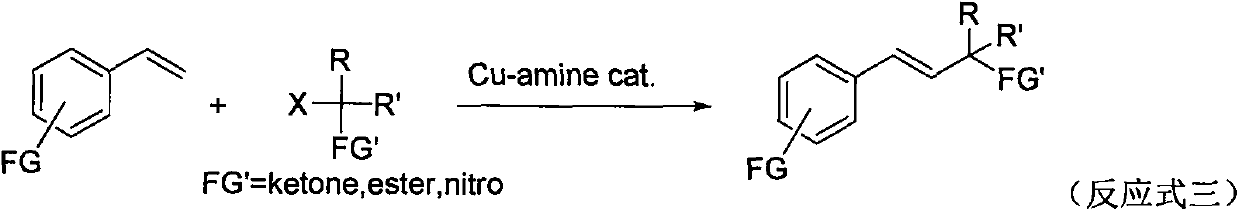

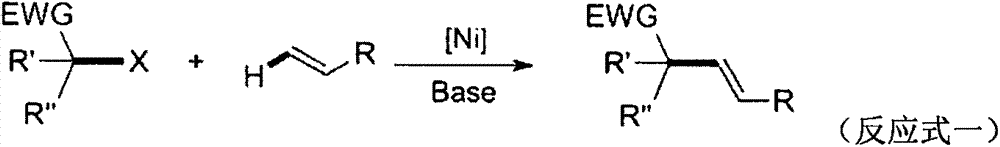

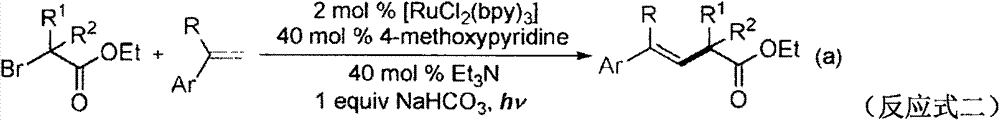

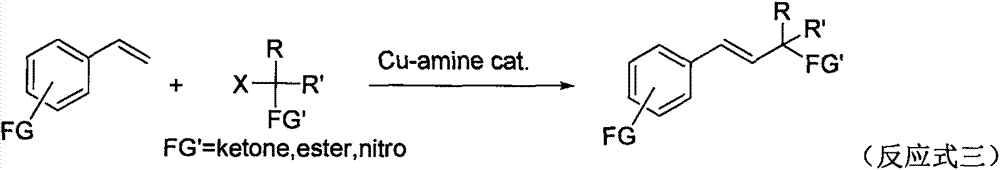

A kind of preparation method of β, γ-unsaturated ester compound

ActiveCN106892818BLow priceCatalytic conditions are mildOrganic compound preparationCarboxylic acid esters preparationPropanoic acidPtru catalyst

Owner:NINGBO UNIV

Efficient purple potato pigment extraction method

InactiveCN110218465AReduce extraction timeImprove extraction efficiencyFood ingredient as colourNatural dyesPectinaseEconomic benefits

The invention relates to an efficient purple potato pigment extraction method. Specifically, the purple sweet potato pigment extraction method comprises the steps of performing enzymolysis treatment on purple sweet potato pulp by using pectinase and cellulase, extracting the purple sweet potato pigment in the enzymolysis solution by using ultrasonic technology, purifying the obtained purple sweetpotato pigment, and the like. The invention combines biological enzyme technology and ultrasonic extraction technology, and has the advantages of simple extraction process, high efficiency, short extraction time, high product recovery rate, no toxicity, convenience for large-scale industrial production and obvious economic benefits.

Owner:AILEX TECH GRP CO LTD +1

Preparation method of beta, gamma-unsaturated ester compound

ActiveCN106892818ALow priceCatalytic conditions are mildOrganic compound preparationCarboxylic acid esters preparationStructural formulaSolvent

The invention discloses a preparation method of beta, gamma-unsaturated ester. A structural formula of the beta, gamma-unsaturated ester is shown in the description. The preparation method of the beta, gamma-unsaturated ester comprises the following steps: adding 1,1-diphenylethlene and 2-bromopropionate into a reaction system containing a silver catalyst, an oxidant, alkali and a solvent for reacting.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com