FeCo/N-C nano composite material as well as preparation method and application thereof

A nanocomposite material and reaction technology, which is applied in the field of FeCo/N-C nanocomposite material and its preparation, can solve problems such as harsh reaction conditions, and achieve the effects of high energy utilization rate, strong reusability, and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of FeCo / N-C nanocomposite material, the steps are:

[0029] a. Preparation of precursors

[0030] 0.12g FeCl 2 ·4H 2 The O powder was dispersed in 20 mL of deionized water, and 0.12 g of Co(NO 3 ) 2 ·6H 2 O powder, stirred at room temperature for 10 minutes, then added 0.25g of NTA and 20mL of isopropanol after the dispersion was completed, stirred at room temperature for half an hour, stirred evenly and moved it to the autoclave, and reacted at 170 ° C for 7 hours; The liquid was centrifuged at 4000 rpm and the precipitate was filtered out. The precipitate was washed with water until neutral and then washed with absolute ethanol for 3 times. The obtained solid sample was placed in a vacuum oven and dried at 60 °C for 12 hours to obtain 0.30 g of the precursor.

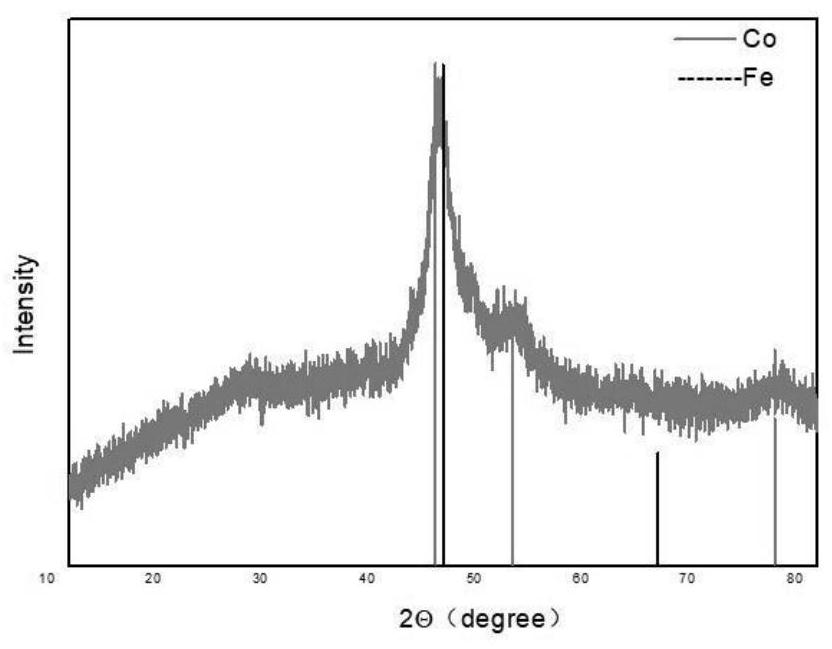

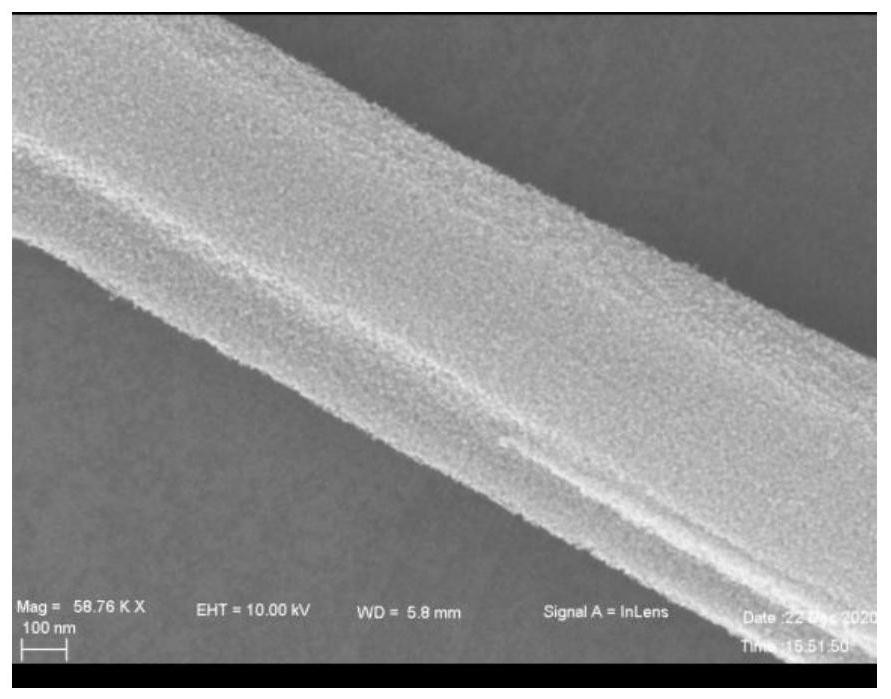

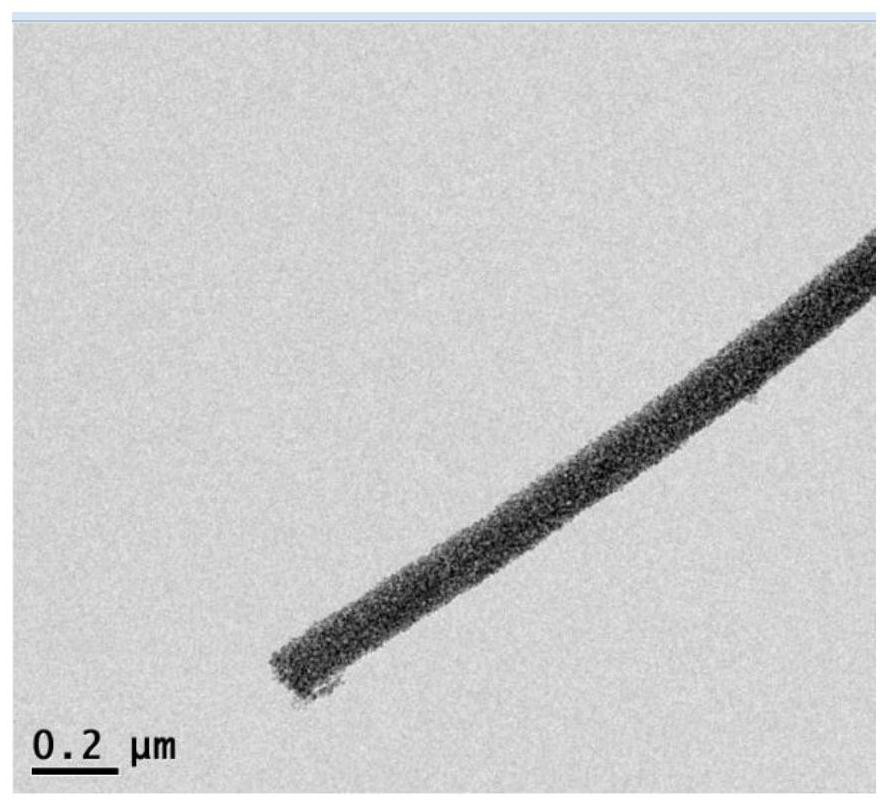

[0031] b. Preparation of FeCo / N-C nanocomposites

[0032] Under argon protection, 0.30 g of the precursor was calcined in a tube furnace, the heating rate was controlled at 5 °C / min, ...

Embodiment 2

[0039] A preparation method of FeCo / N-C nanocomposite material, the steps are:

[0040] a. Preparation of precursors

[0041] 0.12g FeCl 2 ·4H 2 The O powder was dispersed in 20 mL of deionized water, and 0.12 g of Co(NO 3 ) 2 ·6H 2 O powder, stir at room temperature for 10 minutes, add 0.35g of NTA and 20mL of isopropanol after the dispersion is completed, stir at room temperature for half an hour, stir it evenly, move it to the autoclave, and react at 190 ° C for 5 hours; The liquid was centrifuged at 4000 rpm and the precipitate was filtered out. The precipitate was washed with water until it became neutral and then washed three times with absolute ethanol. The obtained solid sample was placed in a vacuum oven and dried at 60 °C for 12 hours to obtain 0.37 g of the precursor.

[0042] b. Preparation of FeCo / N-C nanocomposites

[0043] Under argon protection, 0.37g of the precursor was calcined in a tube furnace, the heating rate was controlled at 5°C / min, the temperat...

Embodiment 3

[0047] A preparation method of FeCo / N-C nanocomposite material, the steps are:

[0048] a. Preparation of precursors

[0049] 0.12g FeCl 2 ·4H 2 The O powder was dispersed in 20 mL of deionized water, and 0.12 g of Co(NO 3 ) 2 ·6H 2 O powder, stir at room temperature for 10 minutes, add 0.45g of NTA and 20mL of isopropanol after the dispersion is completed, stir at room temperature for half an hour, stir it evenly, move it to the autoclave, and react at 180 ° C for 6 hours; The liquid was centrifuged at 4000 rpm and the precipitate was filtered out. The precipitate was washed with water until it became neutral and then washed three times with absolute ethanol. The obtained solid sample was placed in a vacuum oven and dried at 60 °C for 12 hours to obtain 0.43 g of the precursor.

[0050] b. Preparation of FeCo / N-C nanocomposites

[0051] Under argon protection, 0.43g of the precursor was calcined in a tube furnace, the heating rate was controlled at 5°C / min, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com