Preparation method of beta, gamma-unsaturated ester compound

An ester compound and unsaturated technology, applied in the beta field, can solve the problems of unsuitability for industrial production and application, long reaction time, etc., and achieve the effects of mild reaction conditions, low price and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

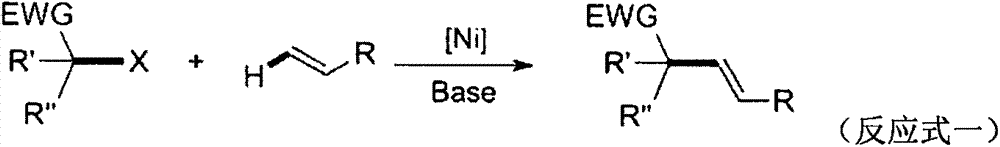

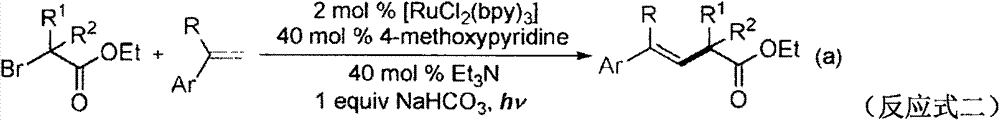

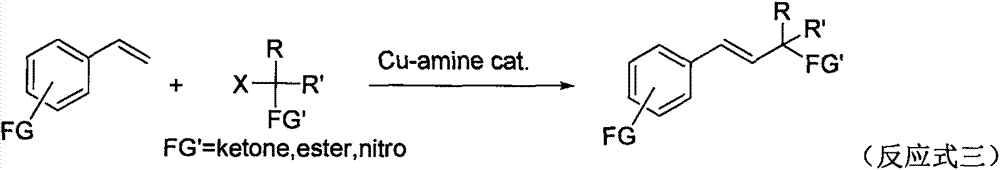

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 72.0 mg (0.4 mmol) of 1,1-diphenylethylene, 99.6 mg (0.6 mmol) of methyl 2-bromopropionate, 9.3 mg (0.04 mmol) of silver oxide, and tert-butyl peroxide into a dry 10 mL schlenk bottle. Alcohol 72.0mg (0.8mmol), triethylamine 80.8mg (0.8mmol), N,N-dimethylacetamide (2mL), and the reaction bottle was stirred at 80°C under an argon atmosphere for 24h. After the reaction was completed, the reaction solution was washed with saturated brine, extracted with ethyl acetate (3×10 mL), and the organic phase was collected and dried by adding anhydrous magnesium sulfate. The organic solvent was removed by rotary evaporation, and the residue was separated by silica gel column chromatography (petroleum ether / ethyl acetate) to obtain the target product (2-methyl-4,4-diphenylbut-3-enoic acid methyl ester), yellow Oily liquid, yield 92%. 1 H NMR (400MHz, CDCl 3 ) δ: 7.40-7.32(m, 3H), 7.25-7.19(m, 7H), 6.12(d, J=10.4Hz, 1H), 3.67(s, 3H), 3.32-3.28(m, 1H), 1.27 (d, J=6.8Hz, 3H); 13...

Embodiment 2

[0027] Add 72.0 mg (0.4 mmol) of 1,1-diphenylethylene, 99.6 mg (0.6 mmol) of methyl 2-bromopropionate, 11 mg (0.04 mmol) of silver carbonate, and tert-butanol peroxide into a dry 10 mL schlenk bottle 72.0mg (0.8mmol), 80.8mg (0.8mmol) of triethylamine, N,N-dimethylacetamide (2mL), and the reaction bottle was stirred at 80°C under an argon atmosphere for 24h. After the reaction was completed, the reaction solution was washed with saturated brine, extracted with ethyl acetate (3×10 mL), and the organic phase was collected and dried by adding anhydrous magnesium sulfate. The organic solvent was removed by rotary evaporation, and the residue was separated by silica gel column chromatography (petroleum ether / ethyl acetate) to obtain the target product (2-methyl-4,4-diphenylbut-3-enoic acid methyl ester). rate of 85%.

Embodiment 3

[0029] Proceed according to the method of Example 1, wherein the difference is that 117 mg (0.8 mmol) of DTBP is added to replace the butanol peroxide to obtain a target product yield of 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com