A kind of resource processing method of carbon dioxide and water highly selective synthesis of ethanol

A carbon dioxide and resource recovery technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve problems such as low catalytic pathway and limited selectivity, and achieve improved conversion rate, reduced energy consumption, and improved operating conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

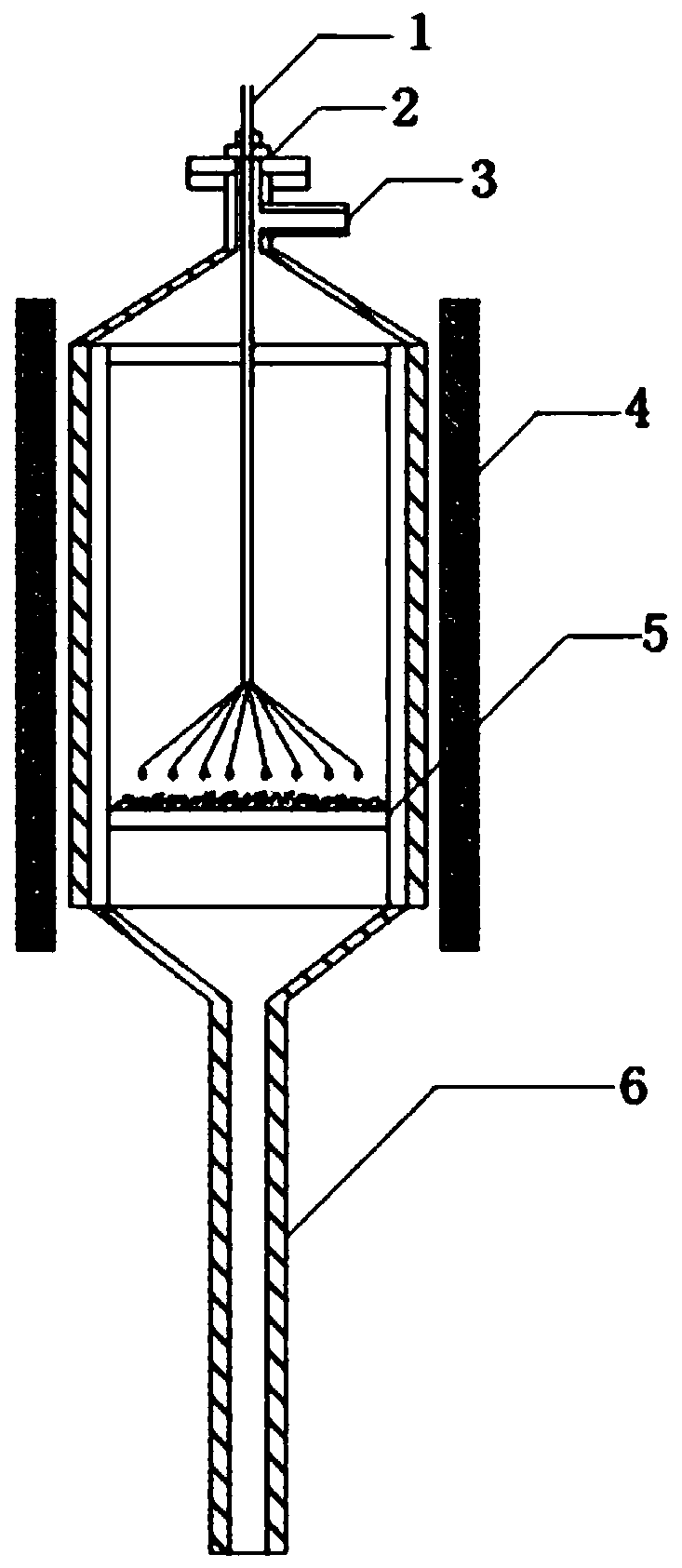

Method used

Image

Examples

Embodiment 1

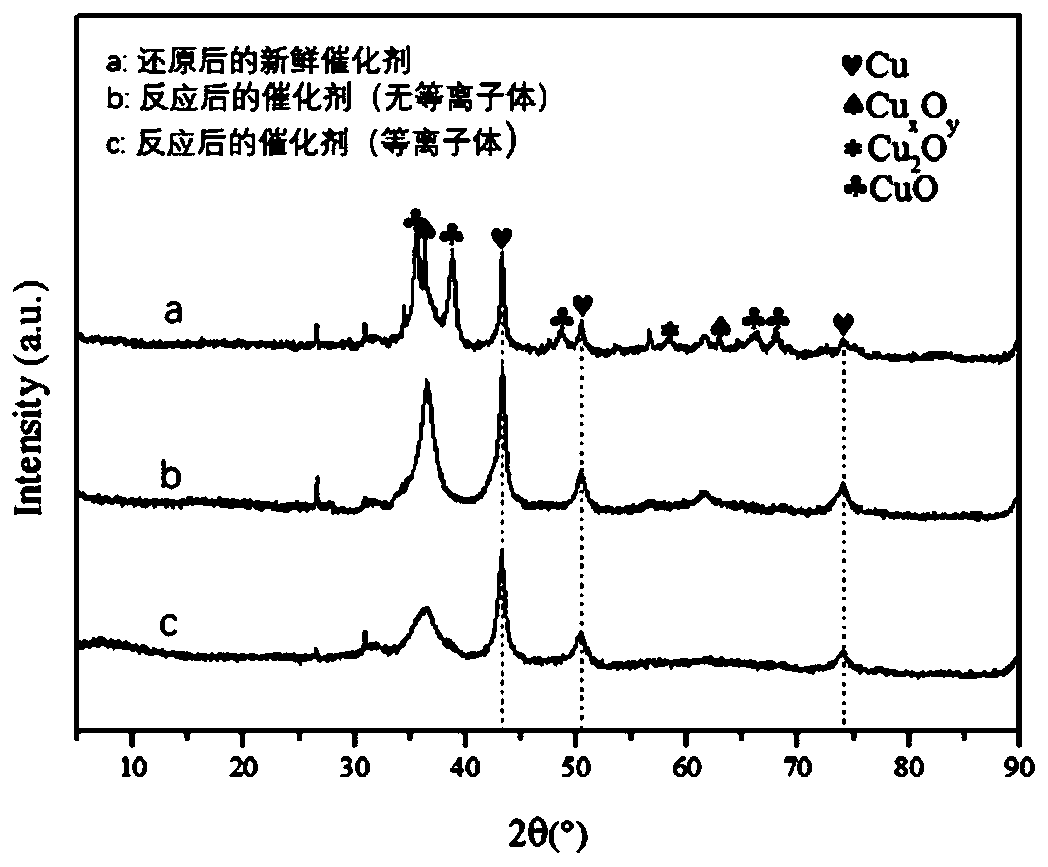

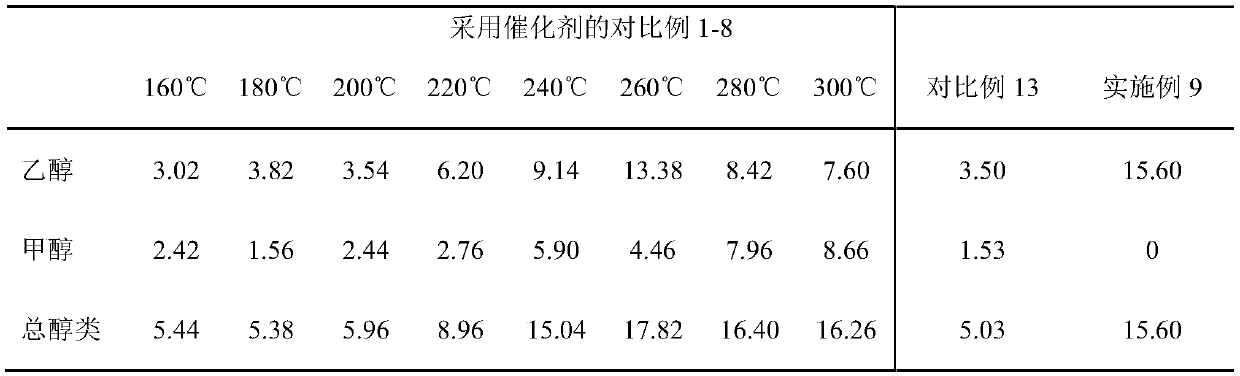

[0075] Weigh 0.5000 g of the copper-zinc-aluminum catalyst and fill it into a quartz tube reactor. before the reaction at N 2 (30mL / min) atmosphere, the temperature was raised to 300°C at a heating rate of 5°C / min, and stabilized for 10min. Access to H 2 (30mL / min) after reducing for 2h, under N 2 (30mL / min) the atmosphere was cooled down to 160°C. The reaction gas was introduced, the flow rate of carbon dioxide was 30mL / min, the mass content of water vapor was 63.12%, and the input power of the non-equilibrium negative corona plasma was 96W. After collecting the liquid phase products, the gas chromatography FID detector was used for detection and analysis.

Embodiment 2

[0077] The difference from Example 1 is that the input power of the unbalanced negative corona plasma is 192W.

Embodiment 3

[0079] The difference from Example 1 is that the input power of the unbalanced negative corona plasma is 288W.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com