Sulfur-fixing agent for carbon-containing pellets and preparation method thereof

A technology of sulfur-fixing agent and carbon pellets, which is applied in the field of iron-making pellets, can solve the problems of large amounts of impurities and metallurgical harmful elements, the inability to directly apply carbon-containing pellets, and reduce the grade of carbon-containing pellets. Achieve obvious sulfur fixation effect, reduce environmental pollution pressure, and reduce metallurgical harmful elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

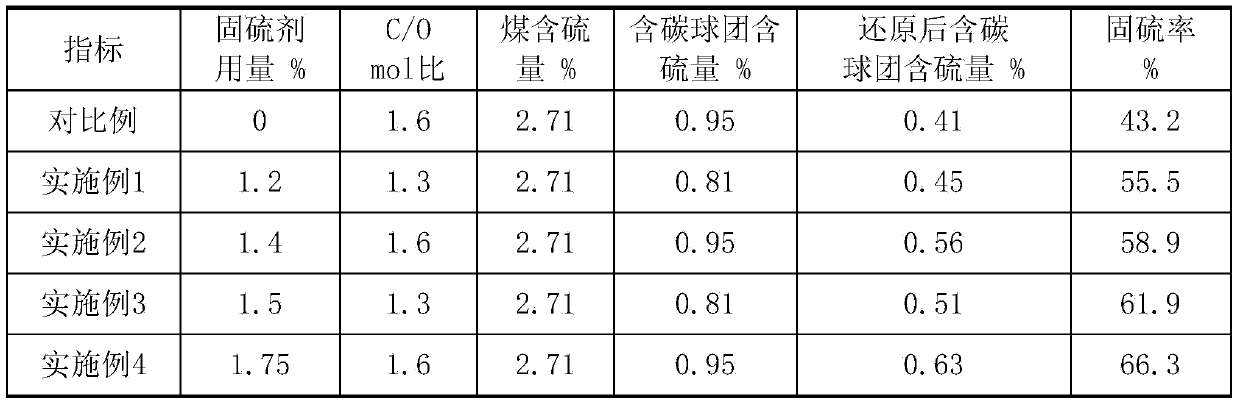

Examples

Embodiment 1

[0041] After the raw material of industrial manganese slag is dried, it is crushed into a powder with a particle size of less than 200 mesh, accounting for more than 90% of the mass ratio, and the composition is analyzed for later use; the red mud is dried to make the water content less than 10%, and then crushed to a particle size of less than 0.125mm. The analytical components are spared. Mix the processed industrial manganese slag, red mud with limestone and dolomite according to the ratio of 25% limestone, 5% industrial manganese slag, 35% red mud and 35% dolomite, and add water to stir. After stirring for 10 minutes, dry to Moisture content is less than 6%. The dried sample was crushed again, and sieved with a 200-mesh sieve to obtain a powder with a particle size of less than 200 mesh and accounting for more than 90% by mass, that is, a powdered sulfur-fixing agent was obtained.

Embodiment 2

[0043] After the raw material of industrial manganese slag is dried, it is crushed into a powder with a particle size of less than 200 mesh, accounting for more than 90% of the mass ratio, and the composition is analyzed for later use; the red mud is dried to make the water content less than 10%, and then crushed to a particle size of less than 0.125mm. The analytical components are spared. Mix the processed industrial manganese slag and red mud with limestone and dolomite evenly according to the ratio of 30% limestone, 5% industrial manganese slag, 35% red mud and 30% dolomite, add a certain amount of water and stir for 12 minutes , dried to a water content of 5%; the dried sample was crushed again, and sieved with a 200-mesh sieve to obtain a powdery sulfur-fixing agent.

Embodiment 3

[0045] After the raw material of industrial manganese slag is dried, it is crushed into a powder with a particle size of less than 200 mesh, accounting for more than 90% of the mass ratio, and the composition is analyzed for later use; the red mud is dried to make the water content less than 10%, and then crushed to a particle size of less than 0.125mm. The analytical components are spared. Mix the processed industrial manganese slag and red mud with limestone and dolomite evenly at the ratio of 30% limestone, 3% industrial manganese slag, 37% red mud and 30% dolomite, add a certain amount of water and stir for 15 minutes Finally, it was dried to a water content of 6%, and the dried sample was crushed again, and sieved with a 200-mesh sieve to obtain a powdery sulfur-fixing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com