Acetylenic ketone compounds and preparing method thereof

A technology of aldehyde compounds and compounds, which is applied in the field of acetylenic compounds and their preparation, can solve the problems of low yield, complicated process, and harsh preparation conditions of acetylenic compounds, etc., and achieves reduced production costs, simple process, and smooth reaction process. Safe and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

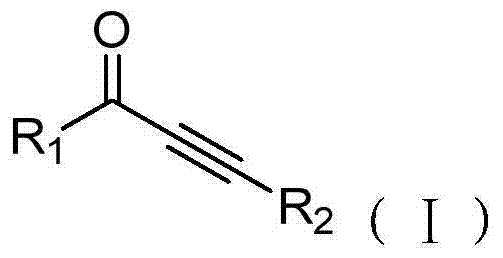

[0069] Correspondingly, the embodiment of the present invention also provides a preparation method of the acetylenic compound of the general formula (I) above. The method comprises the steps of:

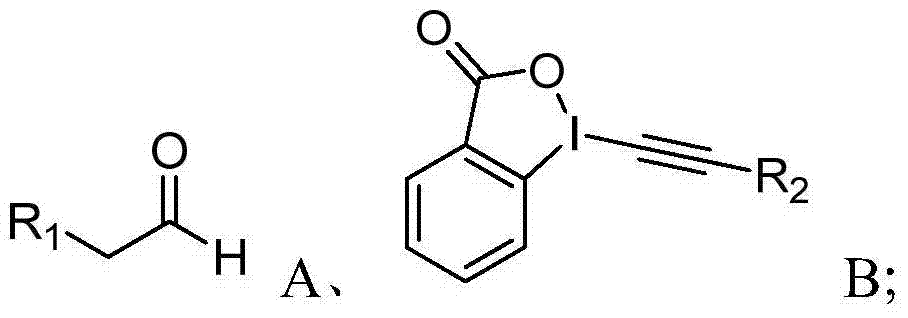

[0070] S01: respectively provide aldehyde compound A and hypervalent iodine compound B represented by the following structural formula:

[0071]

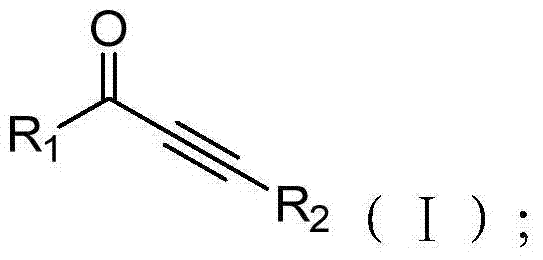

[0072] S02: adding the aldehyde compound A and the hypervalent iodine compound B into a reaction system containing a copper / gold salt catalyst, a secondary amine catalyst, a ligand catalyst and an oxidant to react at a temperature of -20-200°C, Obtain the following structural general formula as the acetylenic compound shown in (I),

[0073]

[0074] Specifically, in the above step S01, R in the molecular structural formula of aldehyde compound A 1 The represented group is as R in the general formula (I) of the acetylenic compound molecular structure above 1 The groups represented are the same. R in the molecular structure formula...

Embodiment 1

[0095] 4-Phenyl-1-triisopropylsilyl-1-yne-3-butanone and its preparation method. The structural formula of the 4-phenyl-1-triisopropylsilyl-1-yne-3-butanone is shown in the following molecular structural formula I1:

[0096]

[0097] Its preparation steps are as follows:

[0098] In a dry 10mL schlenk bottle, add 3.0mg (0.01mmol) of gold trichloride, 3.6mg (0.02mmol) of 4,5-diazofluoren-9-one, and triisopropylsilylethynylphenyliodoyl ketone ( TIPS-EBX) 51.3mg (0.12mmol), 5.0mL anhydrous Et 2 O, replaced with oxygen three times, added 0.1mmol phenylpropanal, 8.2uL pyrrolidine (0.1mmol, 1.0eq), and stirred at 40°C for 10h after sealing the reaction bottle. After the reaction was completed, the reaction solution was filtered through a glass dropper containing silica gel, rinsed with ether, the filtrate was spin-dried, and separated by column chromatography to obtain the target product, a pale yellow oily liquid, with a yield of 72%.

[0099] The product I1 of preparation is...

Embodiment 2

[0101] 4-(4-Bromophenyl)-1-triisopropylsilyl-1-yne-3-butanone and its preparation method. The structural formula of the 4-(4-bromophenyl)-1-triisopropylsilyl-1-yne-3-butanone is shown in molecular structural formula I2 below:

[0102]

[0103] Its preparation method refers to the preparation method of 4-phenyl-1-triisopropylsilyl-1-yne-3-butanone in Example 1, the difference is that 4-bromophenylpropanal (0.1mmol) is used instead of benzene Propionaldehyde, the secondary amine compound catalyst is pyrrolidine (0.1mol). After the reaction was completed, the reaction solution was filtered through a glass dropper containing silica gel, rinsed with ether, the filtrate was spin-dried, and separated by column chromatography to obtain the target product, a light yellow oily liquid, with a yield of 73%.

[0104] The product I2 of preparation is carried out proton nuclear magnetic resonance spectrum (H NMR) analysis, and the result is: 1 H NMR (400MHz, CDCl 3 )δ7.46(d, J=8.2Hz, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com