Technology for producing marsh gas and recycling phosphorus in anaerobic fermentation mode through chicken manure

A technology for anaerobic fermentation and biogas production, applied in products, applications, gas fuels, etc., can solve the problems of orthophosphate concentration decrease, microbial activity inhibition, unfavorable phosphorus recovery, etc., to promote degradation, increase concentration, and alleviate environmental pollution The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

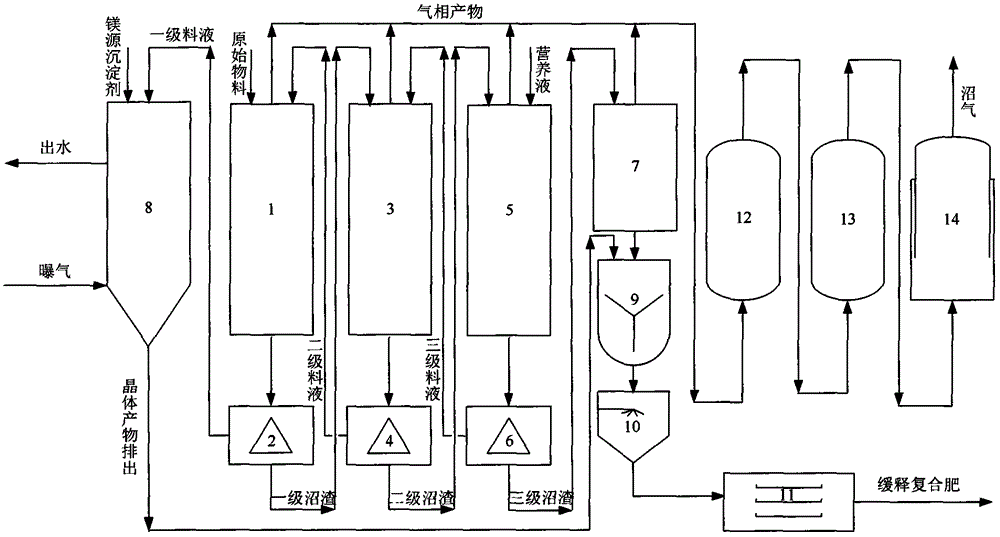

[0011] The process of using chicken manure anaerobic fermentation to produce biogas and reclaim phosphorus of the present invention is as follows: figure 1 shown. figure 1 The meanings of reference signs in are as follows: first-stage fermenter 1, first-stage solid-liquid separator 2, second-stage fermenter 3, second-stage solid-liquid separator 4, third-stage fermenter 5, third-stage solid-liquid separator 6, High temperature digestion tank 7, magnesium ammonium phosphate reactor 8, mixer 9, fertilizer granulator 10, dryer 11, gas-water separation device 12, desulfurization tank 13, gas storage tank 14.

[0012] The invention provides a process for producing biogas and recovering phosphorus by anaerobic fermentation of chicken manure. The process flow is as follows:

[0013] (1) The raw material enters the first-level fermentation tank 1 through the feed port, and undergoes anaerobic fermentation to produce biogas. After the fermentation, the material enters the first-level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com