Method for extracting dietary fiber from potato residues

A technology of potato dregs and dietary fiber, which is applied in food preparation, food science, application, etc., can solve the problems of insignificant improvement in the quality of dietary fiber products, decrease in water holding capacity and expansion force, and high processing costs, so as to reduce the pressure , The proportion of hydrophilic groups is large, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

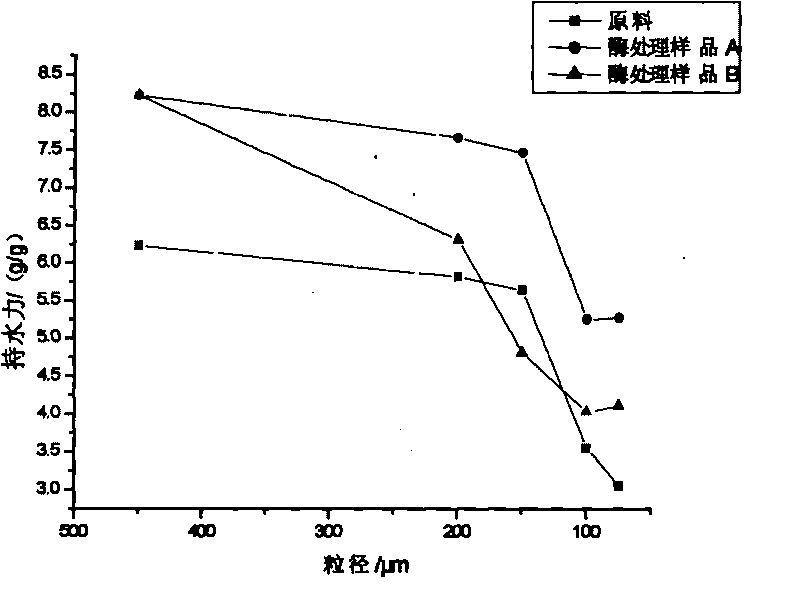

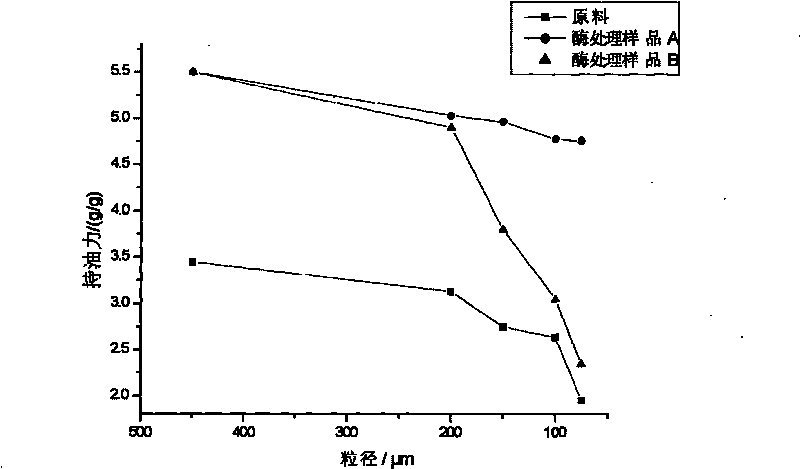

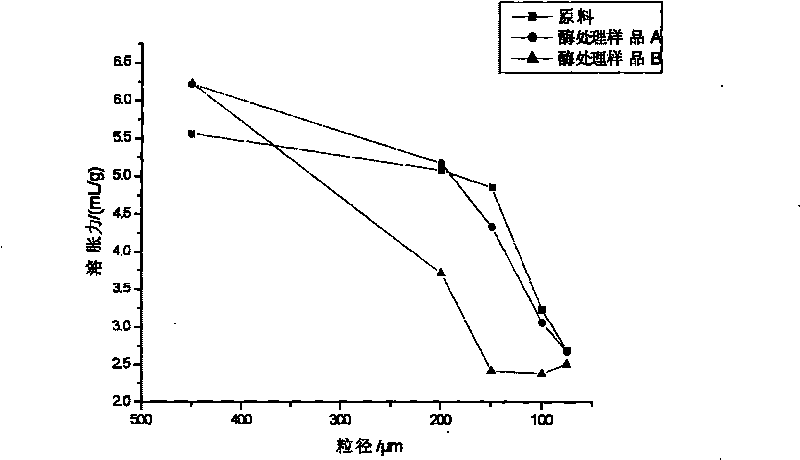

[0033]After the potato residue is dried, crush it through a 40-mesh sieve, take 100g of potato residue powder with a particle size of less than 40 mesh (450μm), add 600ml of water, add 10ul of mixed enzyme at pH 5.0 and temperature 50°C, enzymatically hydrolyze for 0.5h, and then boil 30min, cooled to a temperature of 50°C, at pH 5.0, 10ul of neutral protease was added at a temperature of 50°C, enzymatically hydrolyzed for 1h, then boiled for 30min, cooled to a temperature of 40°C. Filter the potato pulp and separate into filtrate and filter residue. The filter residue was dried at a temperature of 40°C, crushed, and sieved to obtain dietary fiber products of 80 μm, 100 μm, 150 μm, 200 μm, and 450 μm, and the product properties were measured.

Embodiment 2

[0035] After the potato residue is dried, crush it through a 40-mesh sieve, take 100g of potato residue powder with a particle size of less than 40 mesh (450μm), add 1000ml of water, add 50ul of mixed enzyme at pH 7.0 and temperature 60°C, enzymatically hydrolyze for 2h, and then boil for 60min , cooled to a temperature of 60°C, at pH 7.0, 50ul of neutral protease was added at a temperature of 60°C, enzymatically hydrolyzed for 2h, then boiled for 60min, and cooled to a temperature of 60°C. Filter the potato pulp and separate into filtrate and filter residue. The filter residue was dried at a temperature of 60°C, crushed, and sieved to obtain dietary fiber products of 80 μm, 100 μm, 150 μm, 200 μm, and 450 μm, and the product properties were measured.

Embodiment 3

[0037] After the potato dregs are dried, they are pulverized into 80 μm, 100 μm, 150 μm, 200 μm, and 450 μm. The water holding power, oil holding power and swelling property of the five kinds of potato dreg powders are measured respectively, and the obtained results are as follows: Figure 1-3 The raw material curve in is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com