Method for recycling of soybean whey wastewater by membrane separation technology

A technology of soybean whey wastewater and whey wastewater, which is applied in the preparation method of peptides, chemical instruments and methods, applications, etc., can solve the impact on the quality, membrane flux and service life of membrane separation whey protein and oligosaccharide syrup Huge, affecting the normal use of the membrane and other problems, to solve the pollution and separation efficiency drop, improve the comprehensive utilization rate, realize the effect of economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

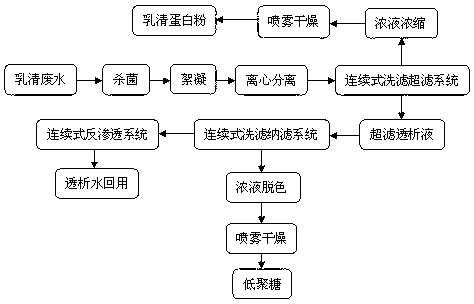

[0033] [Example 1] such as figure 1 Shown, a kind of membrane separation process recycles the method for soybean whey waste water, and it comprises the following steps:

[0034] S1: pretreatment sterilization: heating whey wastewater to 100°C for sterilization;

[0035] S2: Flocculation and centrifugal separation to remove impurities: adjust the pH value of the sterilized whey wastewater to 7.5, adjust the temperature to 50°C, and add CaCl 2 Fully flocculate for 30 minutes, and then use a 9000rpm centrifuge to remove the precipitate formed by impurities, and the light transmittance of the filtrate reaches 81%;

[0036]S3: Continuous separation and recovery of whey protein by ultrafiltration membrane: the whey wastewater after filtering and removing impurities enters the ultrafiltration membrane module. After separation and concentration, the concentrate and dialysate are directly discharged from the membrane module as two streams of effluent. Automatic washing and diafiltr...

Embodiment 2

[0042] [Example 2] such as figure 1 Shown, a kind of membrane separation process recycles the method for soybean whey waste water, and it comprises the following steps:

[0043] S1: pretreatment sterilization: heat the whey wastewater to 80°C for sterilization;

[0044] S2: Flocculation and centrifugal separation to remove impurities: adjust the pH value of the sterilized whey wastewater to 7.0, adjust the temperature to 80°C, and add CaCl 2 After fully flocculating for 50 minutes, the precipitate formed by impurities was removed by a 4000rpm centrifuge, and the light transmittance of the filtrate reached 82%;

[0045] S3: Continuous separation and recovery of whey protein by ultrafiltration membrane: the whey wastewater after filtering and removing impurities enters the ultrafiltration membrane module. After separation and concentration, the concentrate and dialysate are directly discharged from the membrane module as two streams of effluent. Automatic washing and diafilt...

Embodiment 3

[0051] [Example 3] such as figure 1 Shown, a kind of membrane separation process recycles the method for soybean whey waste water, and it comprises the following steps:

[0052] S1: pretreatment sterilization: heating whey wastewater to 90°C for sterilization;

[0053] S2: Flocculation and centrifugal separation to remove impurities: adjust the pH value of the sterilized whey wastewater to 7.2, adjust the temperature to 65°C, and add CaCl 2 After fully flocculating for 40 minutes, the sediment formed by impurities was removed by a 6500rpm centrifuge, and the light transmittance of the filtrate reached 82%;

[0054] S3: Continuous separation and recovery of whey protein by ultrafiltration membrane: the whey wastewater after filtering and removing impurities enters the ultrafiltration membrane module, and the ultrafiltration membrane adopts a negatively charged ultrafiltration membrane with a molecular weight cut-off of 3000-5000, and adopts a continuous separation and concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com