New method for development and utilization of potato residue resource

A potato residue and potato residue powder technology, applied in the biological field, can solve the problems of poor quality and high value utilization, and achieve the effect of reducing the pressure of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

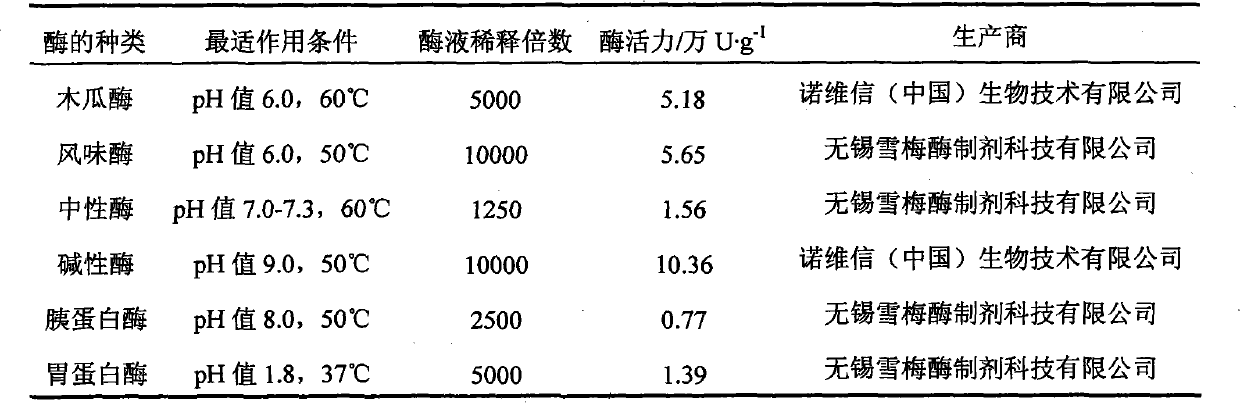

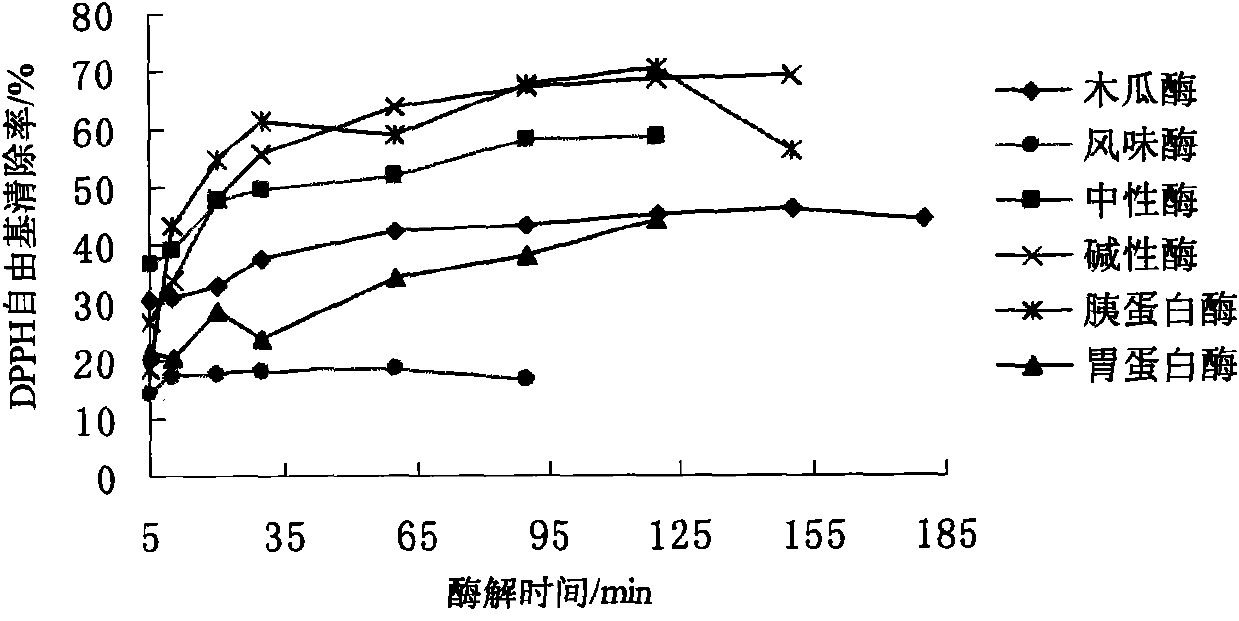

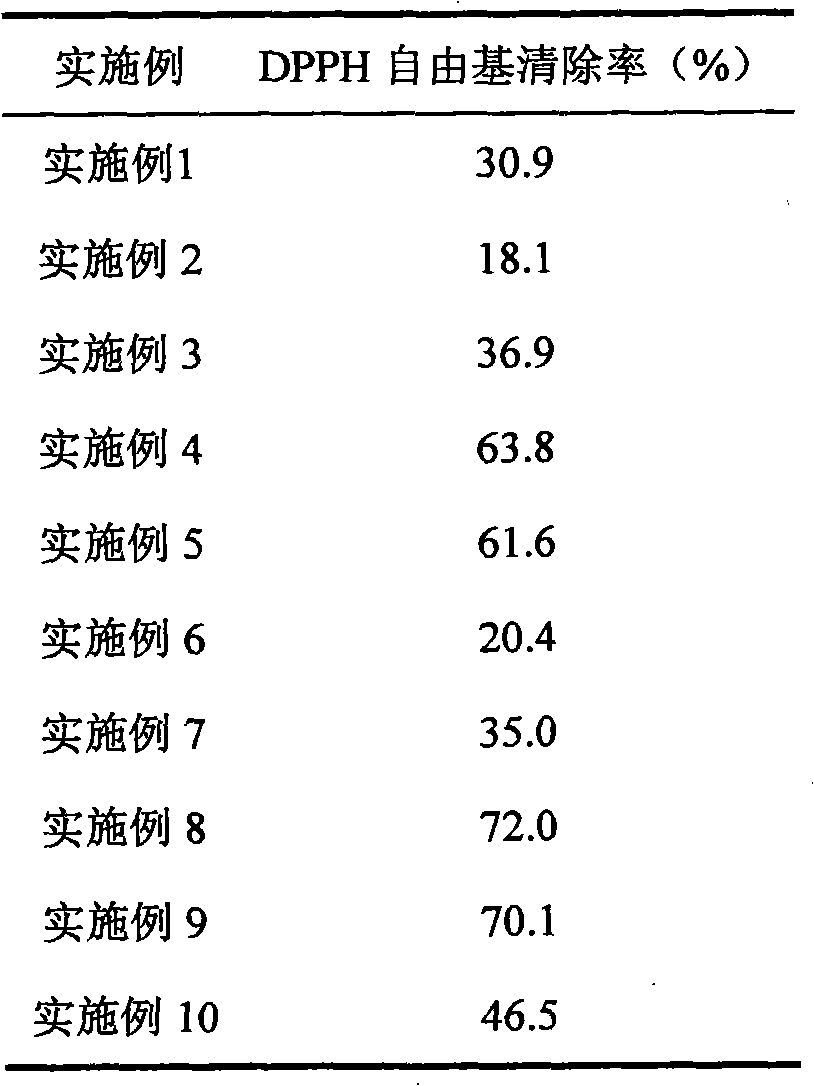

[0033] Take 10 g of potato residue powder, add 200 ml of water, add 0.5 g of papain at pH 6.0 and temperature 60°C, and carry out enzymatic hydrolysis for 150 minutes. Then adjust the pH to 7.0, boil for 10 minutes, cool to 20° C., centrifuge at 3500 rpm for 10 minutes, collect the supernatant, dilute the supernatant 20 times, and measure the DPPH free radical scavenging rate.

Embodiment 2

[0035] Take 10g of potato residue powder, add 200ml of water, add 0.5g of flavor enzyme under the conditions of pH 6.0 and temperature 50°C, and carry out enzymolysis reaction for 30min. Then adjust the pH to 7.1, boil for 10 minutes, cool to 25° C., centrifuge at 3500 rpm for 10 minutes, collect the supernatant, dilute the supernatant 20 times, and measure the scavenging rate of DPPH free radicals.

Embodiment 3

[0037] Take 10g of potato residue powder, add 200ml of water, add 0.5g of neutral protease under the conditions of pH 7.0 and temperature 60°C, and carry out enzymatic hydrolysis reaction for 5 minutes. Then adjust the pH value to 7.0, boil for 10 min, cool to 30°C, centrifuge at 3500 rpm for 10 min, collect the supernatant, dilute the supernatant 20 times, and measure the DPPH free radical scavenging rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com