A comprehensive treatment method for epichlorohydrin production wastewater

A technology for the production of epichlorohydrin and waste water, which is applied in biological water/sewage treatment, natural water treatment, multi-stage water treatment, etc. It can solve problems such as microbial calcification, increased salt content, and dense sludge to improve treatment efficiency. , The treatment process is simple, and the effect of reducing inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

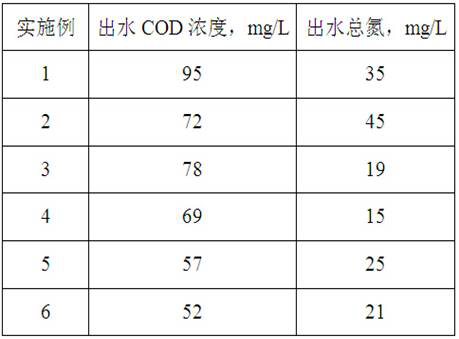

Examples

preparation example Construction

[0030] The specific process of the preparation method of microbial bacterial agent of the present invention is as follows:

[0031] (1) Inoculate Paracoccus FSTB-2, Microbacterium Kitami FSTB-4 and Pseudomonas stutzeri FSTB-5 on FSTB solid medium for activation respectively; denitrifying Paracoccus DN-3 and A Bacteria SDN-3 were respectively inoculated on the corresponding solid medium for activation; spread evenly and placed in a constant temperature incubator at 35°C for activation;

[0032] (2) Use the inoculation loop to inoculate the colonies of Paracoccus FSTB-2, Kitamibacterium FSTB-4 and Pseudomonas stutzeri FSTB-5 on the plate into the corresponding FSTB liquid medium respectively, and use the inoculation loop to Take the colonies of Paracoccus denitrificans DN-3 and Methylobacterium SDN-3 on the plate and inoculate them in the corresponding liquid medium respectively, and culture them with shaking at 30°C and 150rpm for 48 hours to the logarithmic growth phase to obt...

Embodiment 1

[0038] The water quality of epichlorohydrin production wastewater produced by a chemical plant is: calcium ion concentration 8000mg / L, COD (Cr method, the same below) 2000mg / L, salt content 2.5wt%, pH value 11.

[0039] The water quality of molecular sieve catalyst production wastewater produced by a chemical plant is: COD concentration is 40000mg / L, sulfate radical is 200mg / L, salt content is 2.0wt%, ammonia nitrogen concentration is 2000mg / L, nitrate nitrogen is 100mg / L, organic nitrogen is 8000mg / L, the pH value is 12.0, and the suspended solids concentration is 4000mg / L. Concentrated sulfuric acid is used for pretreatment. The quality of wastewater after treatment is: COD concentration 38000mg / L, sulfate radical 12000mg / L, salt content 3.5wt%, ammonia nitrogen 2000mg / L, nitrate nitrogen 100mg / L, organic nitrogen 3000mg / L , the pH value is 8.5, and the suspended matter is 200mg / L. After sulfuric acid pretreatment, the flocculent substances precipitated in the wastewater a...

Embodiment 2

[0043] The water quality of epichlorohydrin production wastewater produced by a chemical plant is: calcium ion concentration 8000mg / L, COD 2000mg / L, salt content 2.5wt%, pH value 12.

[0044] The water quality of molecular sieve catalyst production wastewater produced by a chemical plant is: COD concentration is 40000mg / L, sulfate radical is 200mg / L, salt content is 2.0wt%, ammonia nitrogen concentration is 2000mg / L, nitrate nitrogen is 100mg / L, organic nitrogen is 8000mg / L, the pH value is 12.0, and the suspended solids concentration is 4000mg / L. Concentrated sulfuric acid is used for pretreatment. The quality of wastewater after treatment is: COD concentration 38000mg / L, sulfate radical 12000mg / L, salt content 3.5wt%, ammonia nitrogen 2000mg / L, nitrate nitrogen 100mg / L, organic nitrogen 3000mg / L , the pH value is 8.5, and the suspended matter is 200mg / L. After sulfuric acid pretreatment, the flocculent substances precipitated in the wastewater are recycled after proper tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com