High-concentration acrylonitrile wastewater treatment method

A technology of acrylonitrile wastewater and treatment method, which is applied in multi-stage water treatment, natural water treatment, heating water/sewage treatment and other directions, can solve the problems of up-to-standard discharge, biochemical treatment, insufficient recovery of acrylonitrile, etc., and achieve considerable economic benefits , The process is simple and energy-saving, and the effect of reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A high-concentration acrylonitrile wastewater, the feed rate is 1000kg / h, and the content of acrylonitrile is 0.1wt%.

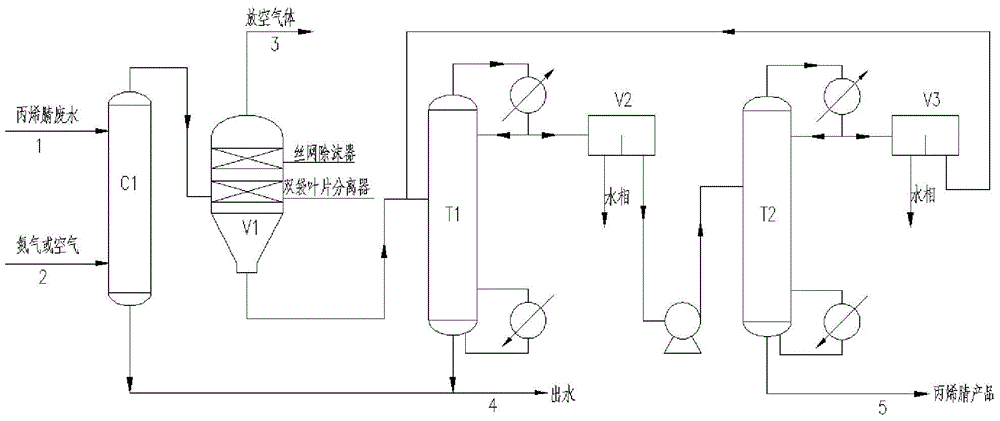

[0035] The acrylonitrile waste water 1 enters the upper part of the stripping tower C1, and the fractionation tower is a packed tower, and the filler is IMTP40# bulk packing, the packing height is 5 meters, and the compressed air 2 is fed from the bottom of the stripping tower C1, the flow rate is 290kg / h, and the air pressure 0.2MPa (absolute pressure), the effluent after removing acrylonitrile is discharged from the bottom of the C1 tower, the content of acrylonitrile in the effluent is 1mg / L, and the flow rate of the effluent is 995kg / h. The mist material entrained with acrylonitrile and water at the top of the C1 tower enters the gas-liquid separator V1. In the gas-liquid separation, it passes through the two-stage gas-liquid separation of the double-bag blade separator and the wire mesh demister respectively. The gas phase at the top is used as Ve...

Embodiment 2

[0039] A high-concentration acrylonitrile wastewater, the feed rate is 5000kg / h, and the content of acrylonitrile is 0.5wt%.

[0040] The acrylonitrile waste water 1 enters the upper part of stripping tower C1, and the fractionating tower is a packed tower. The filler is Pall ring bulk packing, and the packing height is 10 meters. 0.2MPa (absolute pressure), the effluent after removing acrylonitrile is discharged from the bottom of the C1 tower, the acrylonitrile content of the effluent is 0.6mg / L, and the effluent flow rate is 4936.5kg / h. The mist material entrained with acrylonitrile and water at the top of the C1 tower enters the gas-liquid separator V1. In the gas-liquid separation, it passes through the two-stage gas-liquid separation of the double-bag blade separator and the wire mesh demister respectively. The gas phase at the top is used as The air is vented, the substrate discharge is acrylonitrile aqueous solution, the acrylonitrile content is 76.5%, and the output i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com